Test block for detecting coating of wind power tower barrel

A technology for wind power towers and test blocks, applied in the field of ultrasonic testing, can solve the problems of large number of welds, uneconomical, time-consuming, etc., and achieve the effects of good detection effect, strong practicability, and convenient data comparison

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

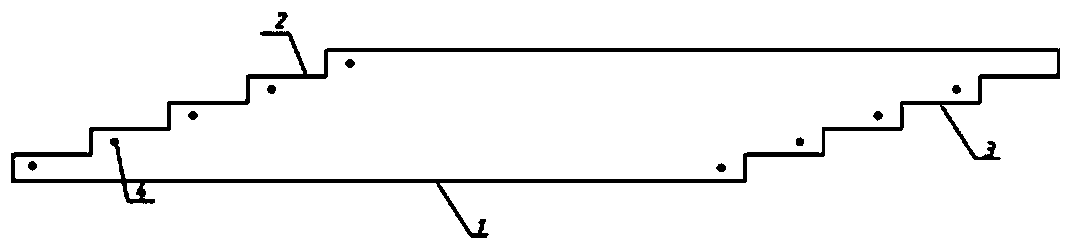

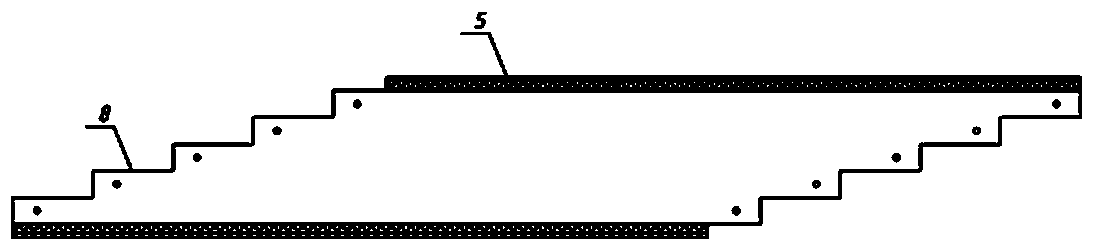

[0021] Such as figure 1 Or as shown in 3 or 4, a wind turbine tower coating detection test block of the present invention includes a test block body 1, the front side of the test block body 1 is provided with a positive step structure 2, and the reverse side of the test block body 1 is provided There is a reverse step structure 3 that can be installed in conjunction with the positive step structure 2. The positive step structure 2 and the reverse step structure 3 are centrally symmetrically distributed around the center line of the test block body 1, wherein the top surface of the test block body 1 and There are contrast areas 5 on the bottom. By providing the positive ladder structure 2 and the reverse ladder structure 3, a plurality of test block bodies 1 can be spliced together, which not only reduces the size of the test block body 1, but also has the characteristics of being convenient to carry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com