Reservoir rock hole crack three-dimensional visualization and gas flow simulation method

A technology of gas flow and simulation method, which is applied in the field of three-dimensional visualization of rock pores and fissures and simulation of gas flow, which can solve the problems of incomparable distribution and strength indicators of rock pores and fissures, unreliable and accurate results, and time-consuming problems. , to achieve the effects of eliminating sample discreteness, promoting safe development, and reducing the probability of disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing, the present invention will be further described, embodiment is exemplary, only for revealing and explaining the present invention, in order to fully understand the present invention, but does not therefore limit the present invention to described implementation within the scope of the example.

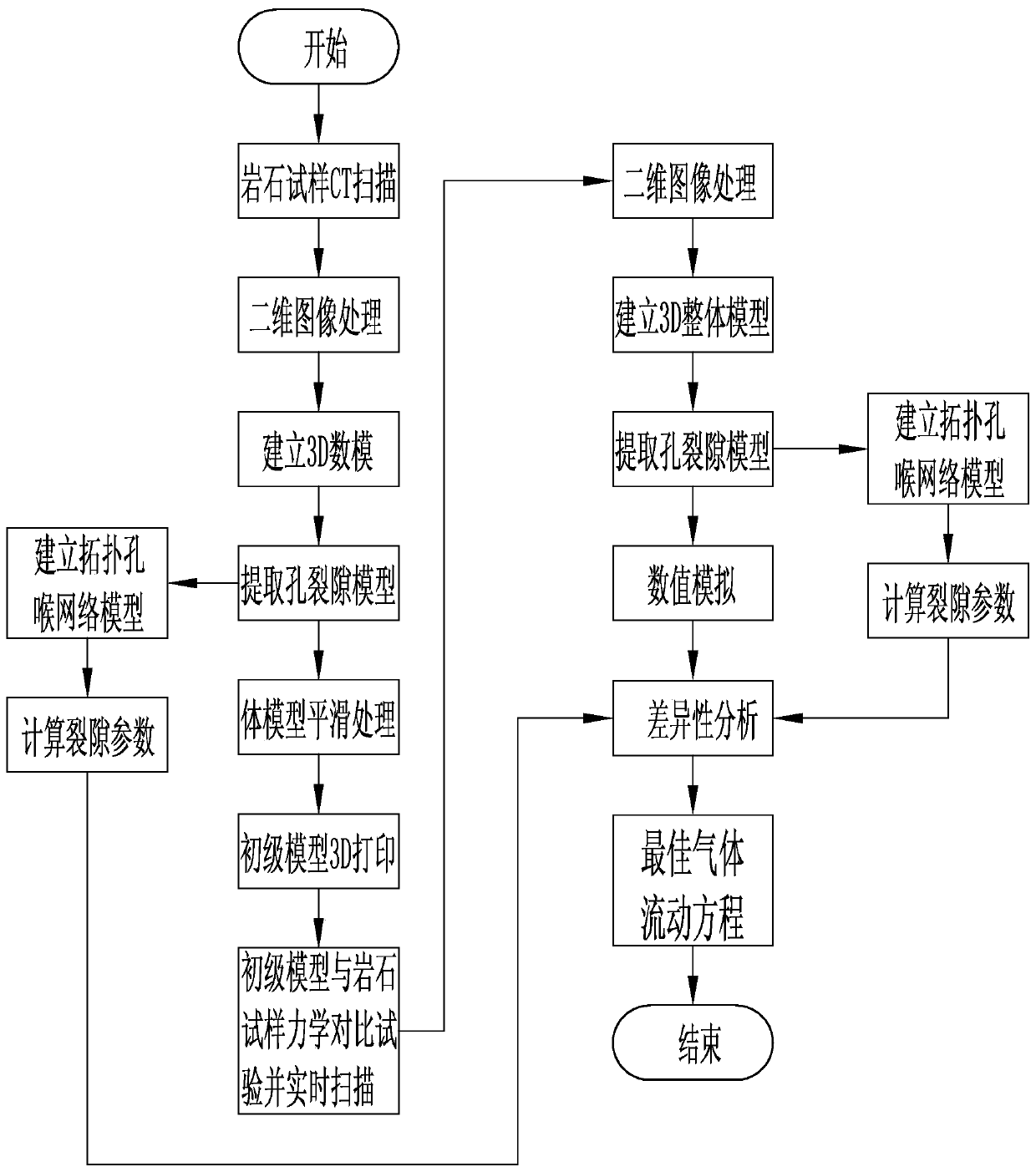

[0046] see figure 1 A method for three-dimensional visualization of reservoir rock pores and fractures and simulation of gas flow, comprising the following steps:

[0047] S1. Scanning of the original state of the rock sample and printing of the rock sample model: the rock sample model data is obtained by performing a three-dimensional CT scan on the rock sample in a non-stressed state, and the rock sample model is printed by processing the scanned data and 3D printing technology 3D printing;

[0048] S2, mechanical seepage physical experiment and real-time CT scanning simulation: conduct mechanical seepage physical experiment an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com