Nickel cobalt lithium manganate material with trace metal impurities, preparation method and application

A technology of nickel-cobalt lithium manganese oxide and trace metals, which is applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of ineffective removal of metal impurities, high energy consumption, and corrosion of equipment materials, so as to promote industrial development, The effect of simple preparation method and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] see figure 1 , the embodiment of the present invention provides a kind of preparation method of nickel cobalt lithium manganate material with trace metal impurity, comprising the following steps:

[0033] Step S1: providing nickel-cobalt lithium manganese oxide sintered material, said nickel-cobalt lithium manganese oxide sintered material including metal impurities;

[0034] Step S2: providing a metal chloride solution, adding ammonia water to the metal chloride solution, so that the metal chloride in the metal chloride solution and the ammonia water undergo a complex reaction to form an alkaline etching solution;

[0035] Step S3: mixing the nickel-cobalt-lithium-manganese-oxide sintered material and the alkaline etching solution, so that the alkaline etching solution etches the metal impurities in the nickel-cobalt-lithium-manganese-oxide sintered material to obtain the Nickel cobalt lithium manganese oxide material with trace metal impurities.

[0036] In step S1,...

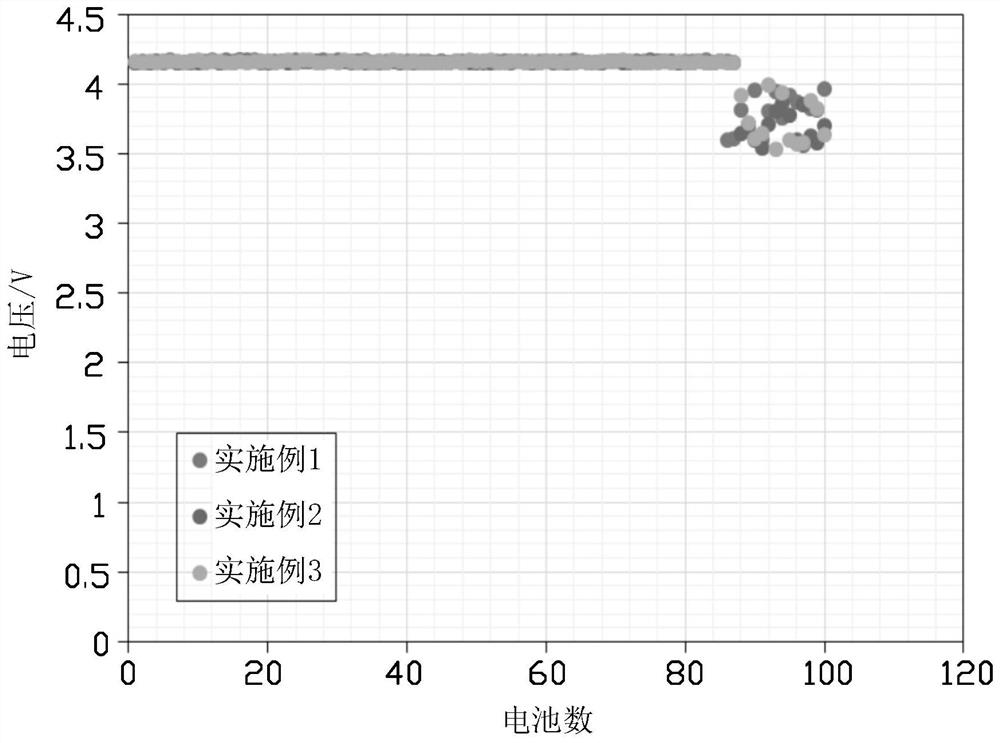

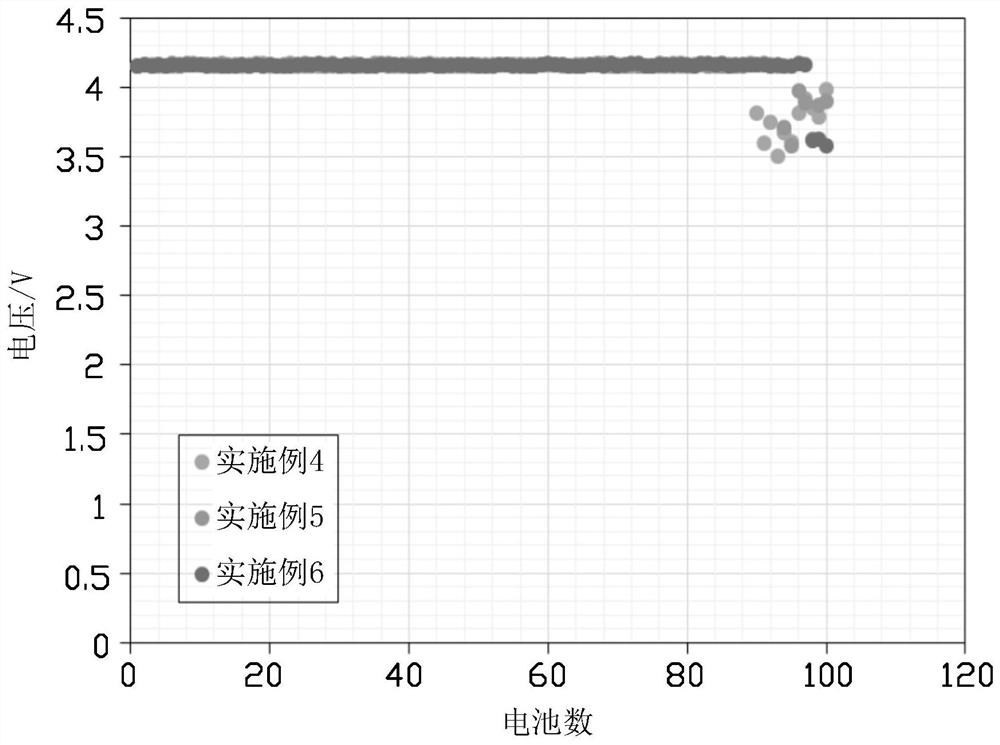

Embodiment 1

[0067] Convert lithium carbonate to lithium salt and Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 After the transition metal oxide is uniformly mixed in a ball mill mixer, the mixed material is obtained, wherein the lithium atom (Li) of lithium carbonate in the mixed material is mixed with Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 The molar ratio of the total content of metal atoms (Ni, Co, and Mn) in the medium is 1.05:1; the mixed material is sintered at a temperature of 920°C, kept for 12 hours, and the sintering atmosphere is air; a jaw crusher or a roller is used The sintered sintered agglomerate is coarsely crushed by a machine, and then mechanically crushed to obtain nickel-cobalt-lithium manganese oxide material.

[0068] Prepare CuCl 2 solution, to the CuCl 2 Add ammonia water to the solution, the CuCl 2 The solution undergoes a complexation reaction with ammonia water: CuCl 2 +4NH 3 →Cu(NH 3 ) 4 Cl 2 , forming Cu(NH 3 ) 4 Cl 2 Alkaline etchant, the CuCl 2 The molar concentration ...

Embodiment 2

[0071] Different from Example 1: the transition metal oxide is Ni 0.4 co 0.3 mn 0.3 (OH) 2 ; Lithium atom of lithium carbonate and Ni 0.4 co 0.3 mn 0.3 (OH) 2 The molar ratio of the total content of metal atoms in the medium is 1.04:1; the sintering temperature is 910°C.

[0072] Prepare CrCl 3 solution, to the CrCl 3 Add ammonia water to the solution, the CrCl 3 The solution undergoes a complexation reaction with ammonia water: CrCl 3 +4NH 3 →Cr(NH 3 ) 4 Cl 3 , forming Cr(NH 3 ) 4 Cl 3 Alkaline etchant, the Cr(NH 3 ) 4 Cl 3 The molar concentration of the solution is 0.015mol / L, and the pH of the alkaline etching solution is 10.

[0073] Other steps are the same as in Example 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com