Vertical shaft-type crushing machine with differential function

A vertical shaft crusher, functional technology, applied in grain processing and other directions, to achieve the effect of reducing equipment and infrastructure investment, increasing the single-machine crushing ratio, and simplifying the crushing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

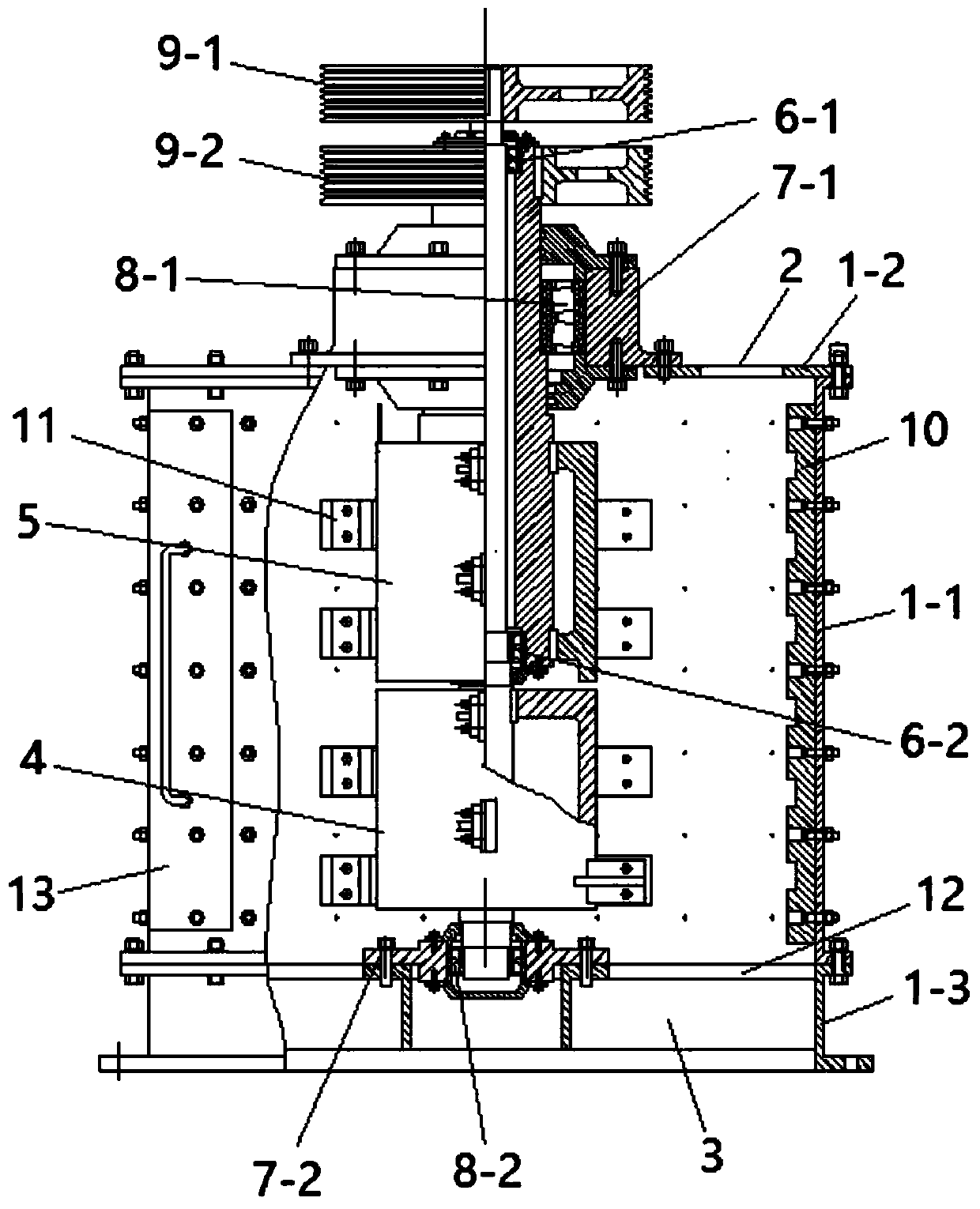

[0019] Referring to the accompanying drawings, the embodiments of the present invention are illustrated and described by taking a plurality of single-stage rotors as two single-stage rotors, that is, a long-axis rotor and a short-axis rotor, respectively, as follows:

[0020] A vertical shaft crusher with a differential speed function, including a box body and two single-stage rotors, the box body includes a cylinder body 1-1, and cover plates respectively installed on the top of the cylinder body 1-1 by means of bolts 1-2 and the base 1-3 installed at the bottom of the cylinder 1-1, the cover plate 1-2 is provided with a feed port 2, and the inside of the base 1-3 is connected with the lower port of the cylinder 1-1 Hollow structure, forming the discharge port 3;

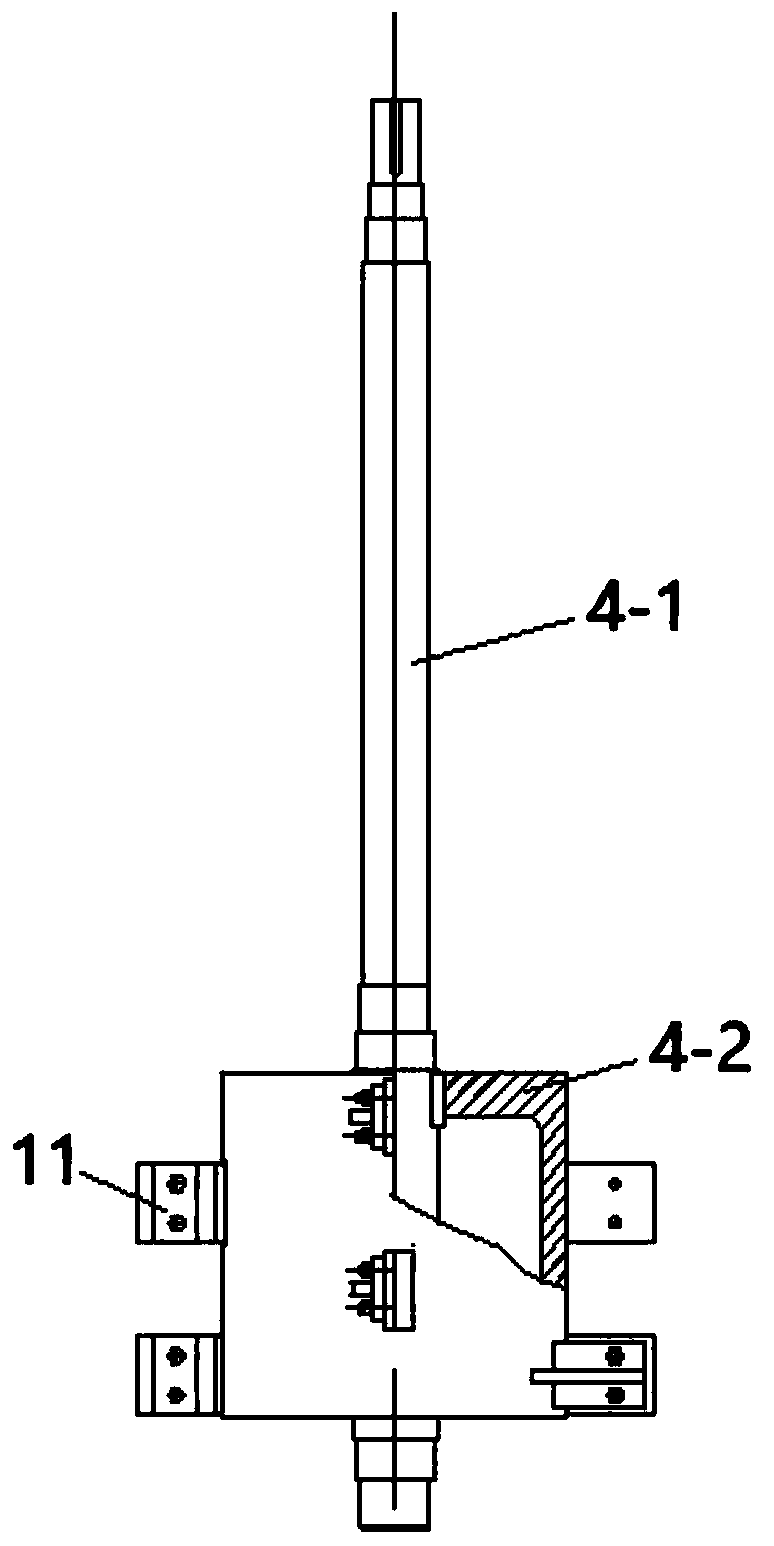

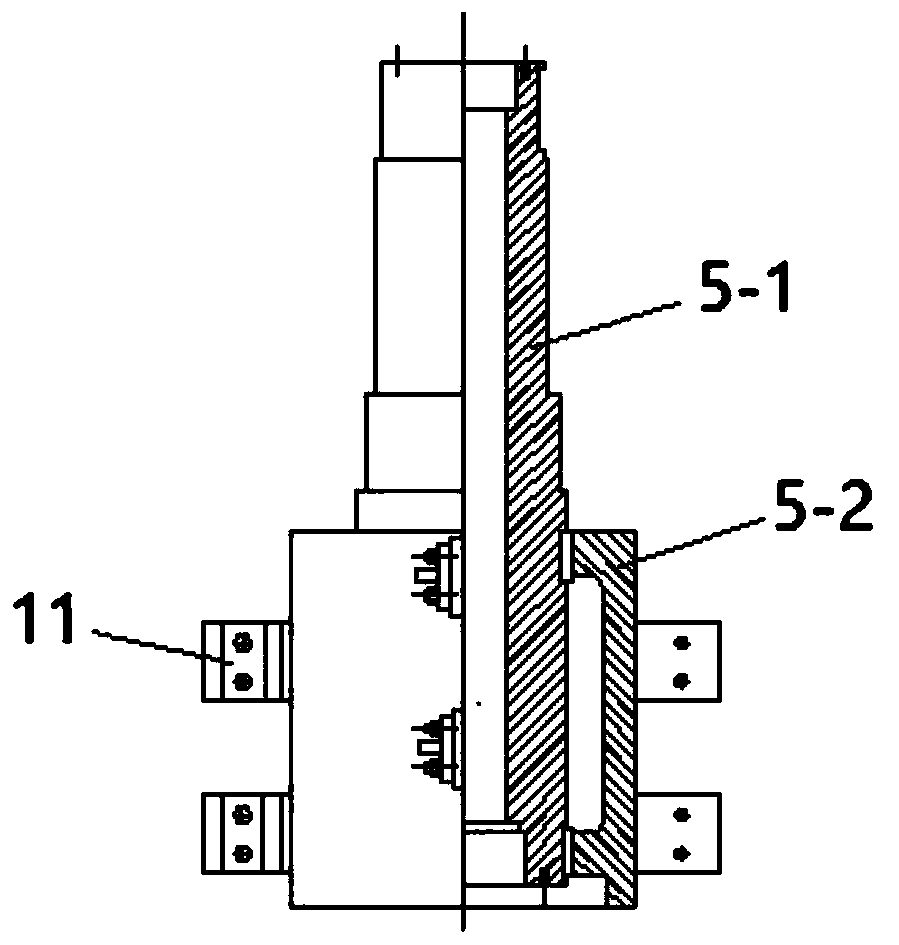

[0021] The two single-stage rotors are respectively the long-axis rotor 4 and the short-axis rotor 5, the rotating shaft 4-1 of the long-axis rotor 4 is coaxial with its rotor body 4-2, and the rotating shaft 5-1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com