Flow coefficient calibration and flowmeter verification method and standard flow device

A standard flow rate and flow coefficient technology, applied in the field of flowmeter verification, can solve the problems of the accuracy and accuracy of the verification results, flow loss, and affecting the weighing results of electronic scales, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

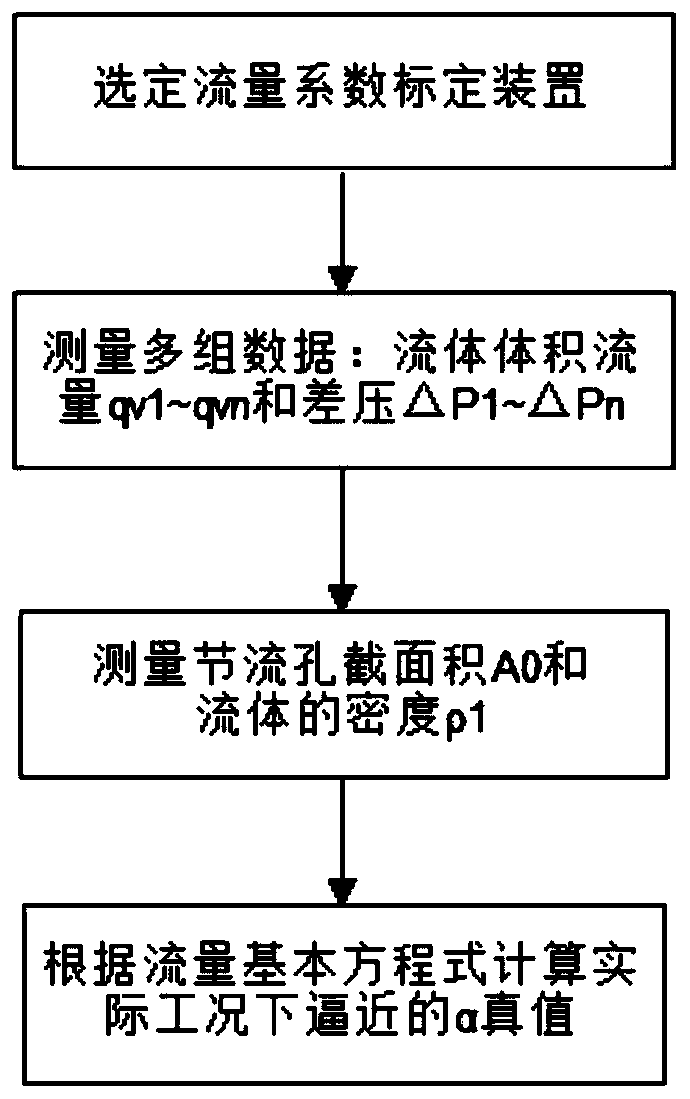

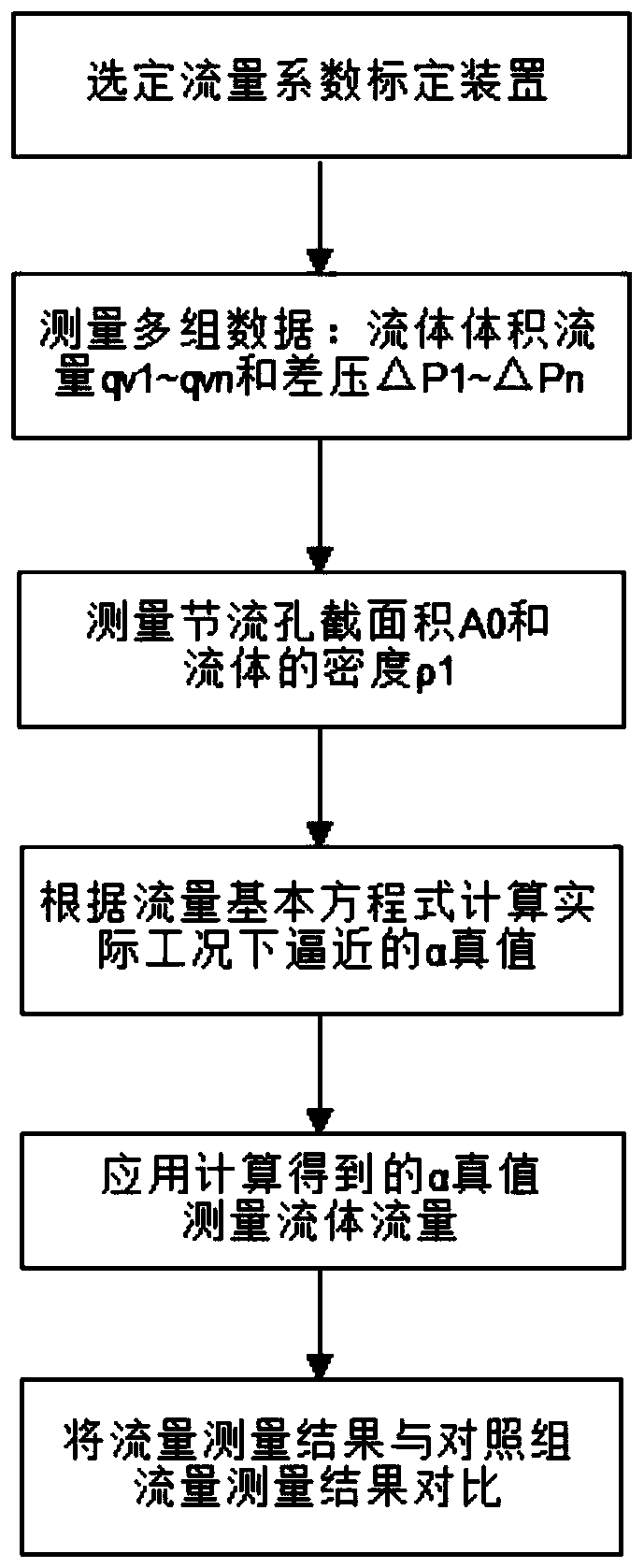

[0057] This embodiment provides a flow coefficient calibration method, such as figure 1 shown, including the following steps:

[0058] S1. Select the standard flow device with the differential pressure flowmeter to be tested as the flow coefficient calibration device;

[0059] S2. Use a standard flow device to measure the flow of the fluid to obtain the first set of data: volume flow q v1 and the differential pressure △P output by the differential pressure flowmeter 1 ;

[0060] S3. Repeat step S2 several times to obtain several sets of data: volume flow q v2 ~q vn and the differential pressure △P output by the differential pressure flowmeter 2 ~△P n ;

[0061] S4. Measure and calculate the cross-sectional area of the orifice of the differential pressure flowmeter, and measure the density of the measured fluid under working conditions;

[0062] S5. Several sets of data measured in steps S2~S3: volume flow q v1 ~q vn , differential pressure △P 1 ~△P n , the data c...

Embodiment 2

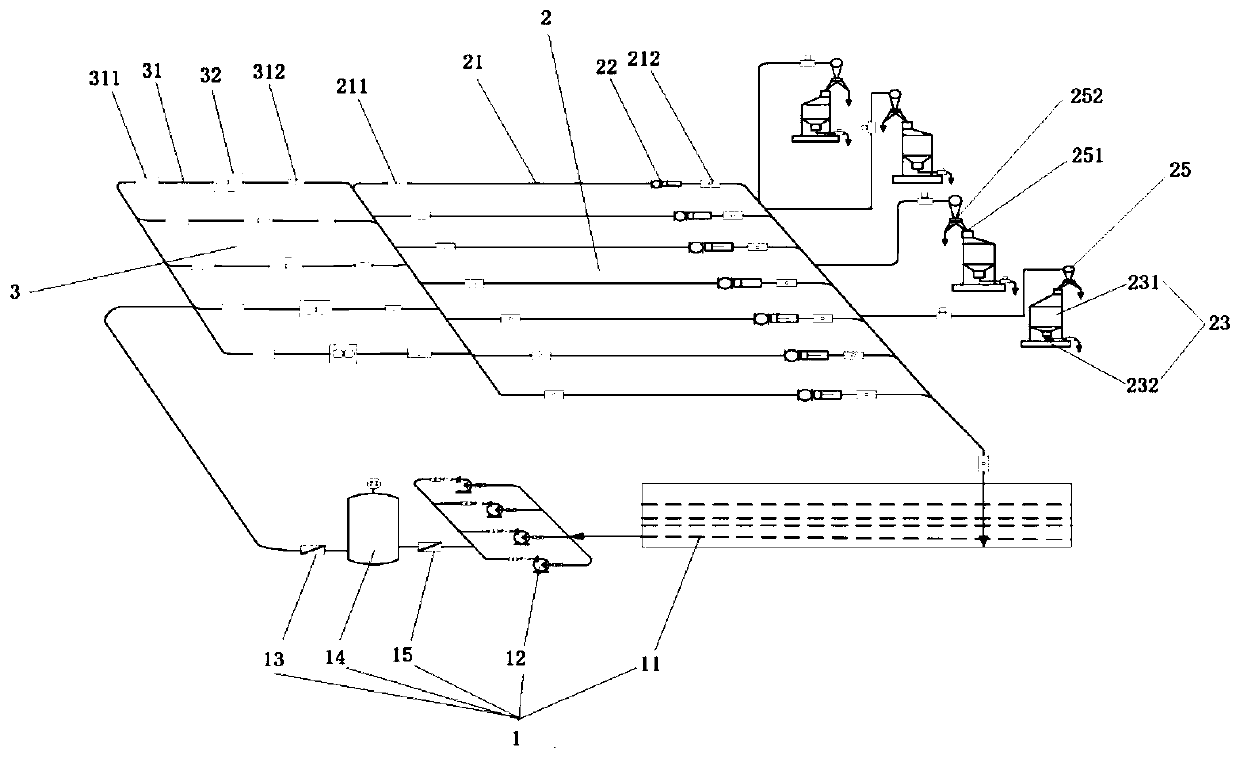

[0078] This embodiment provides a standard flow device, such as image 3 As shown, it includes a fluid supply system 1 , a first verification pipeline group 2 connected to the fluid supply system 1 at one end, and a control system 4 .

[0079] The fluid supply system 1 includes a liquid storage tank 11, a pump 12 arranged on one side of the liquid storage tank 11 for driving fluid flow, and a first switch valve 13 used to control pipeline circulation and cut-off, the first switch valve 13 is located at the pump 12 and the first verification pipeline group 2. A surge tank 14 for increasing the stability of the fluid in the pipeline is provided between the pump 12 and the first switch valve 13 , and a second switch valve 15 is provided between the pump 12 and the surge tank 14 .

[0080] The first test pipeline group 2 includes several first test pipelines 21 connected in parallel with different pipe diameters. A differential pressure flowmeter 22 to be tested is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com