Multi-stage crusher rotor with differential function

A technology of crushers and rotors, applied in grain processing, etc., to achieve the effect of simplifying the crushing process, reducing equipment and infrastructure investment, and increasing the crushing ratio of a single machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

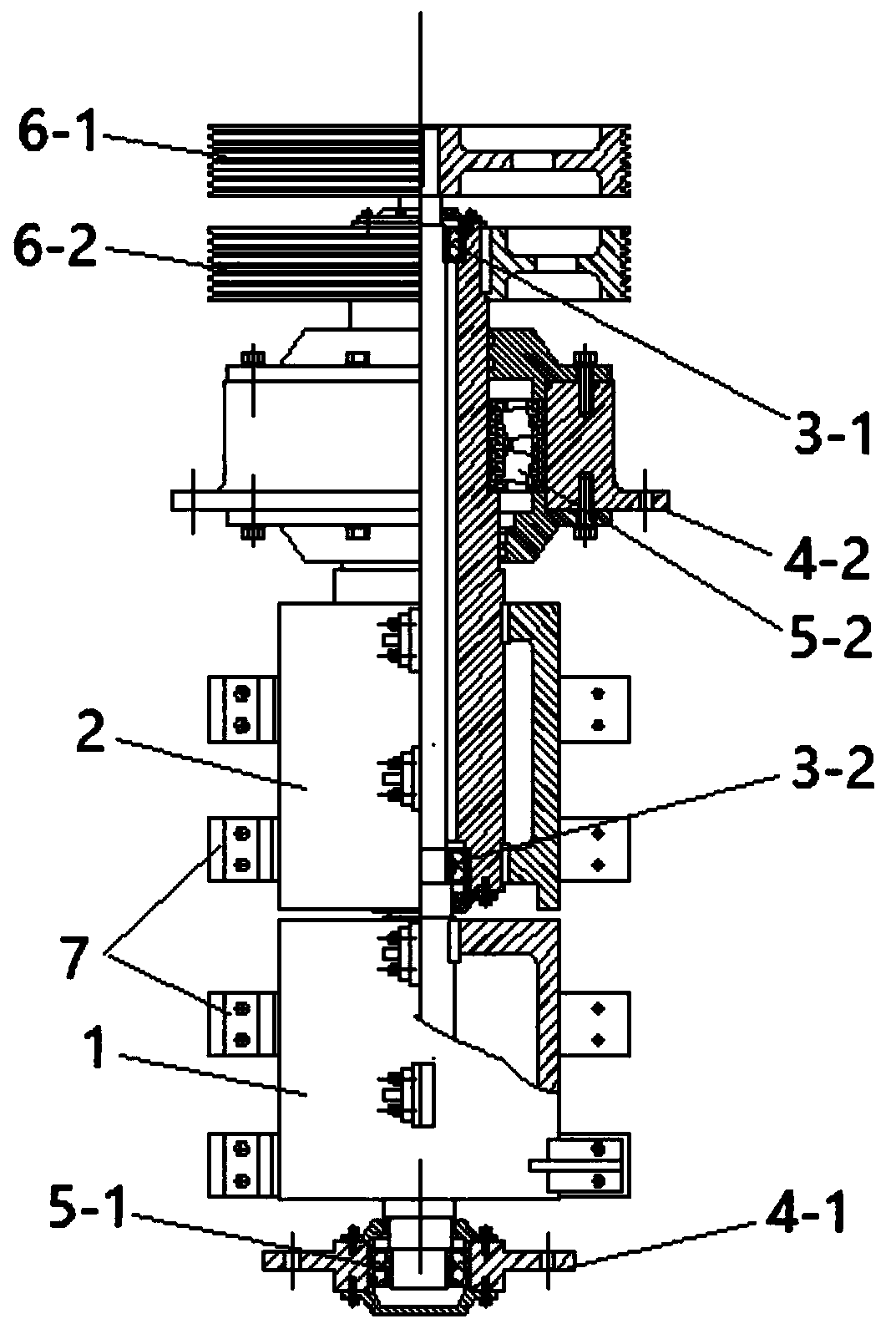

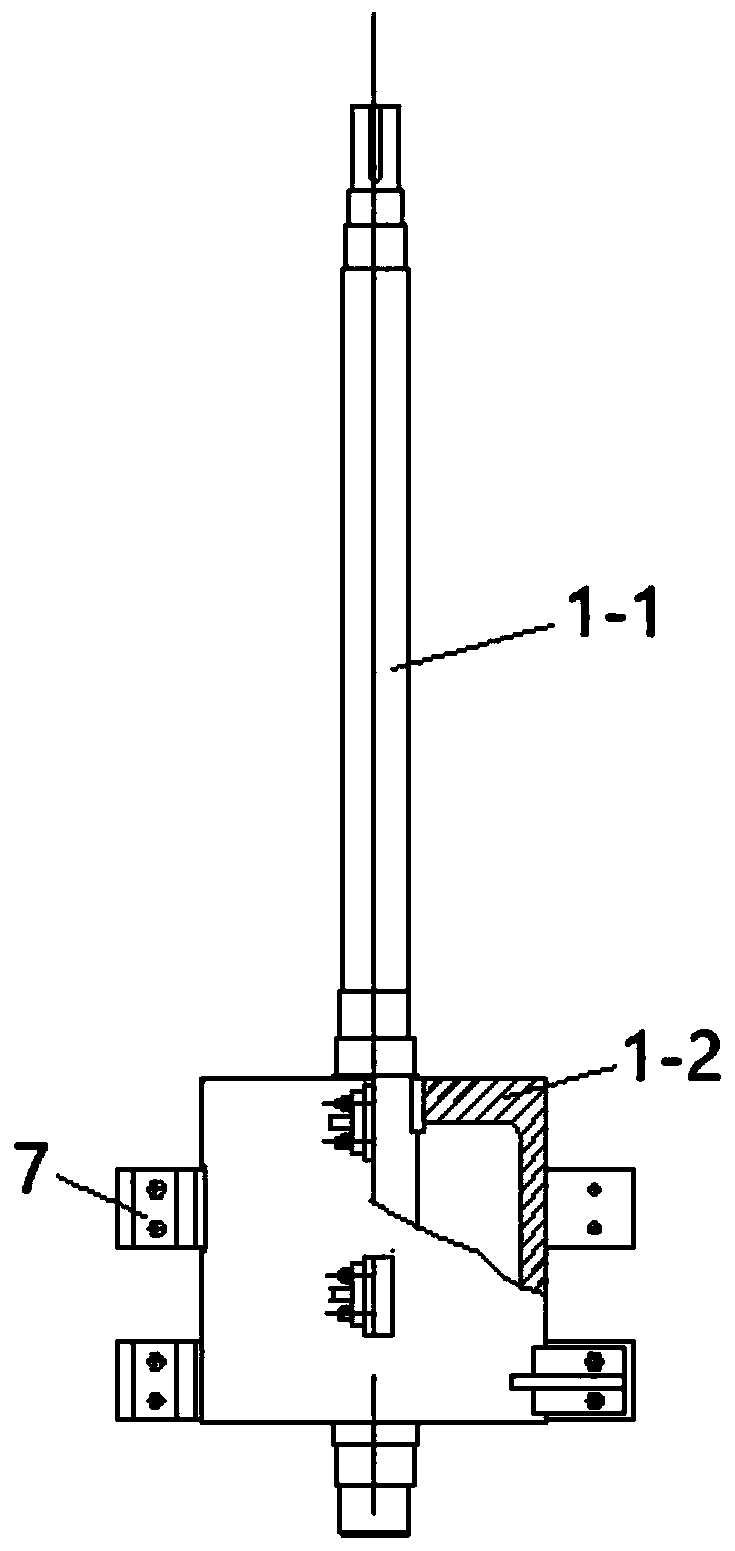

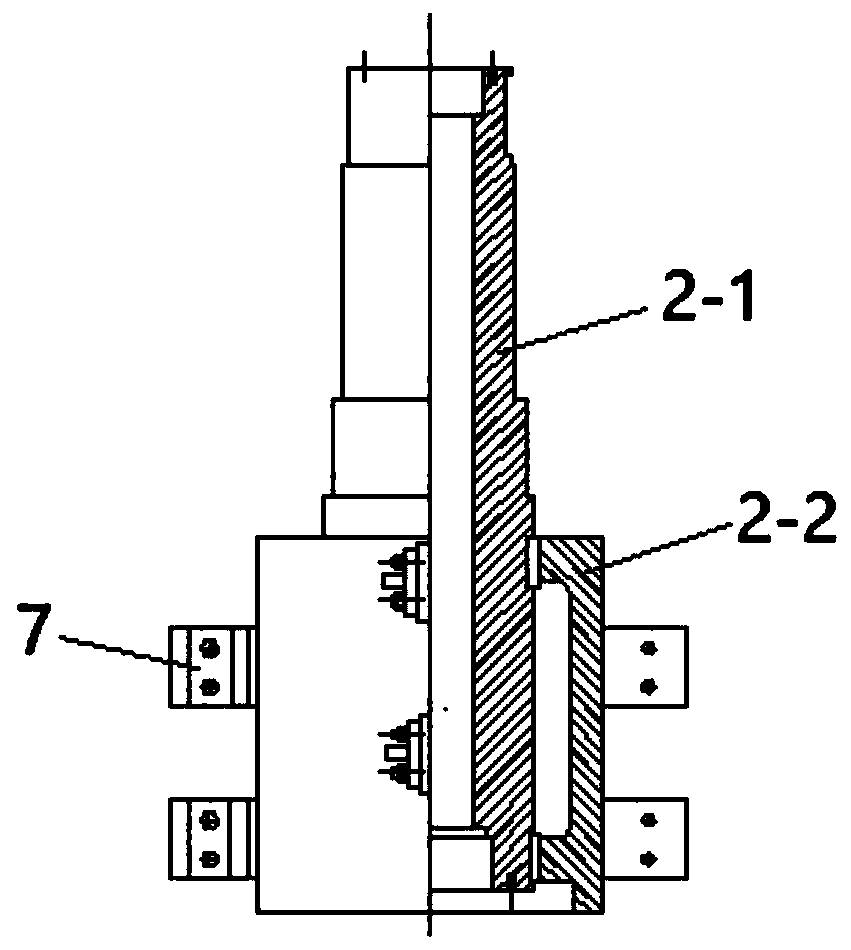

[0019] Referring to the accompanying drawings, the embodiments of the present invention are illustrated and described by taking a plurality of single-stage rotors as two single-stage rotors, that is, a long-axis rotor and a short-axis rotor, respectively, as follows:

[0020] A multi-stage crusher rotor with a differential function, including two single-stage rotors, respectively a long-axis rotor 1 and a short-axis rotor 2, the shaft 1-1 of the long-axis rotor 1 is coaxial with its rotor body 1-2 line, the rotating shaft 2-1 of the short-axis rotor 2 is coaxial with its rotor body 2-2, the rotating shaft 1-1 of the long-axis rotor 1 can be a solid shaft or a hollow shaft, and the rotating shaft 2-1 of the short-axis rotor 2 A hollow shaft is used, set on the rotating shaft 1-1 of the long-axis rotor 1, and coaxial with the rotating shaft 1-1 of the long-axis rotor 1, and the rotor body 1-2 of the long-axis rotor 1 and the rotor of the short-axis rotor 2 The body 2-2 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com