Multifunctional stringed material cutting and penetrating device

A multi-functional, cutting-knife technology, applied in fish threading devices, transportation and packaging, meat cutting/trimming, etc., can solve the problems of low production efficiency, not too large, cumbersome operation, etc., to improve production efficiency, reduce The effect of preparation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

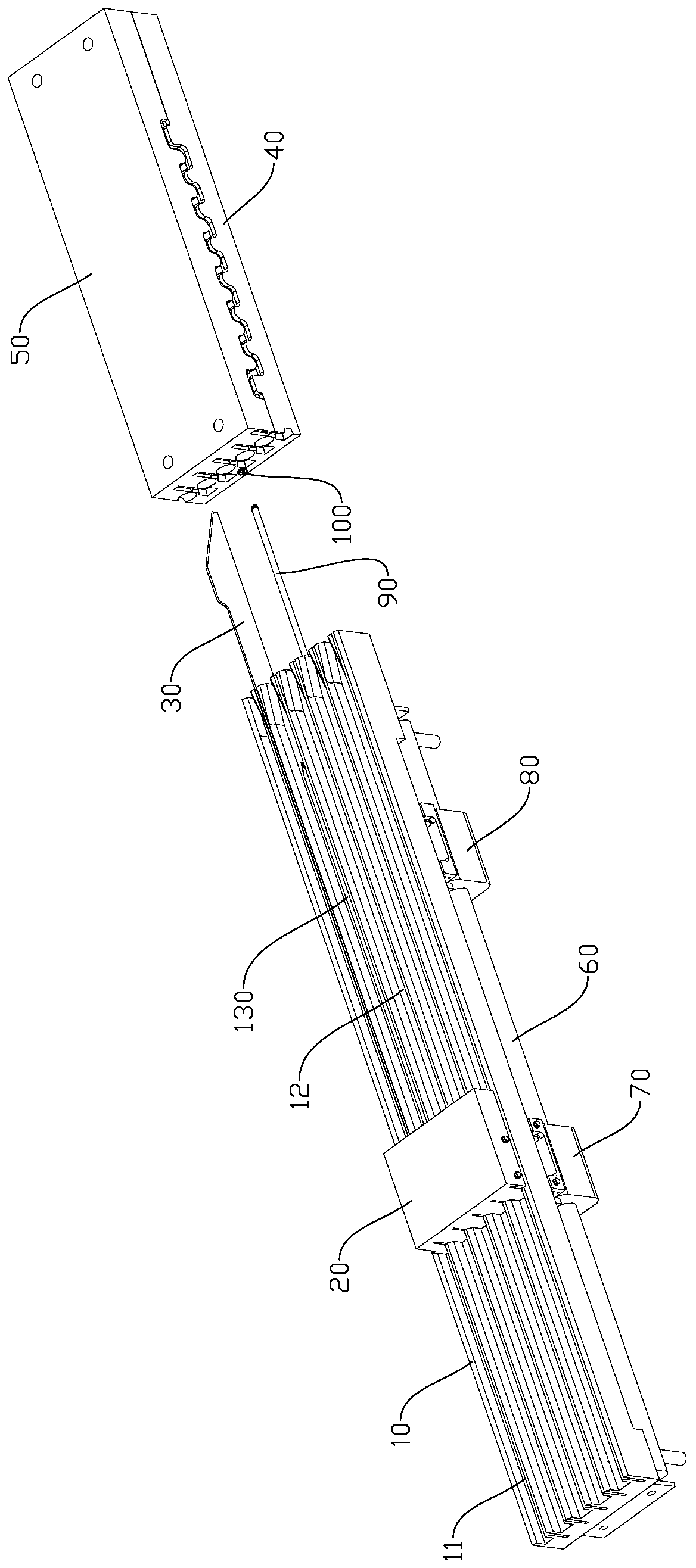

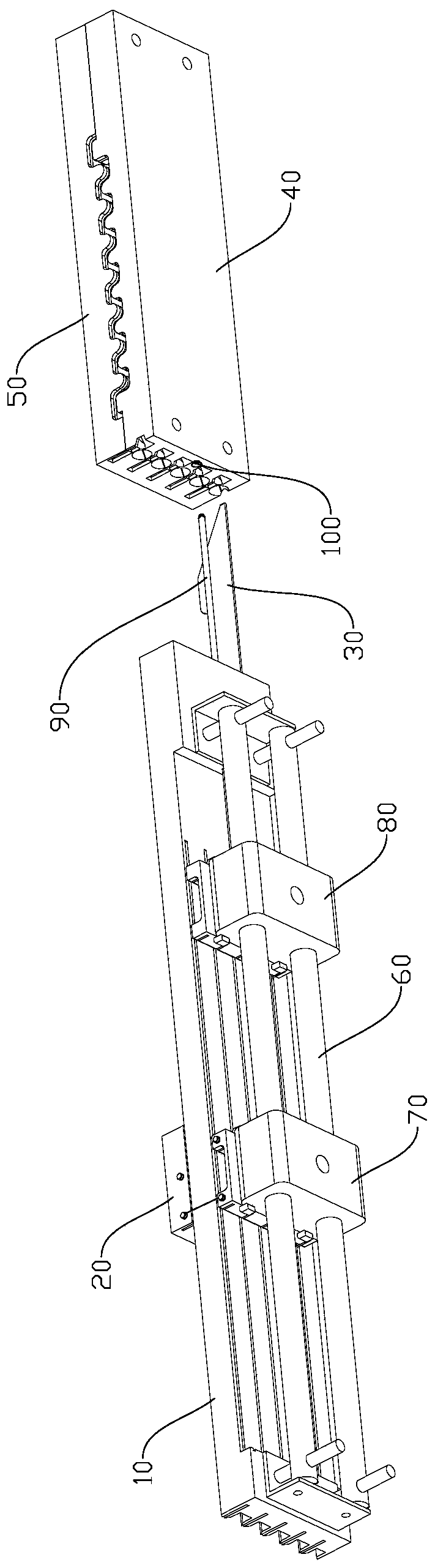

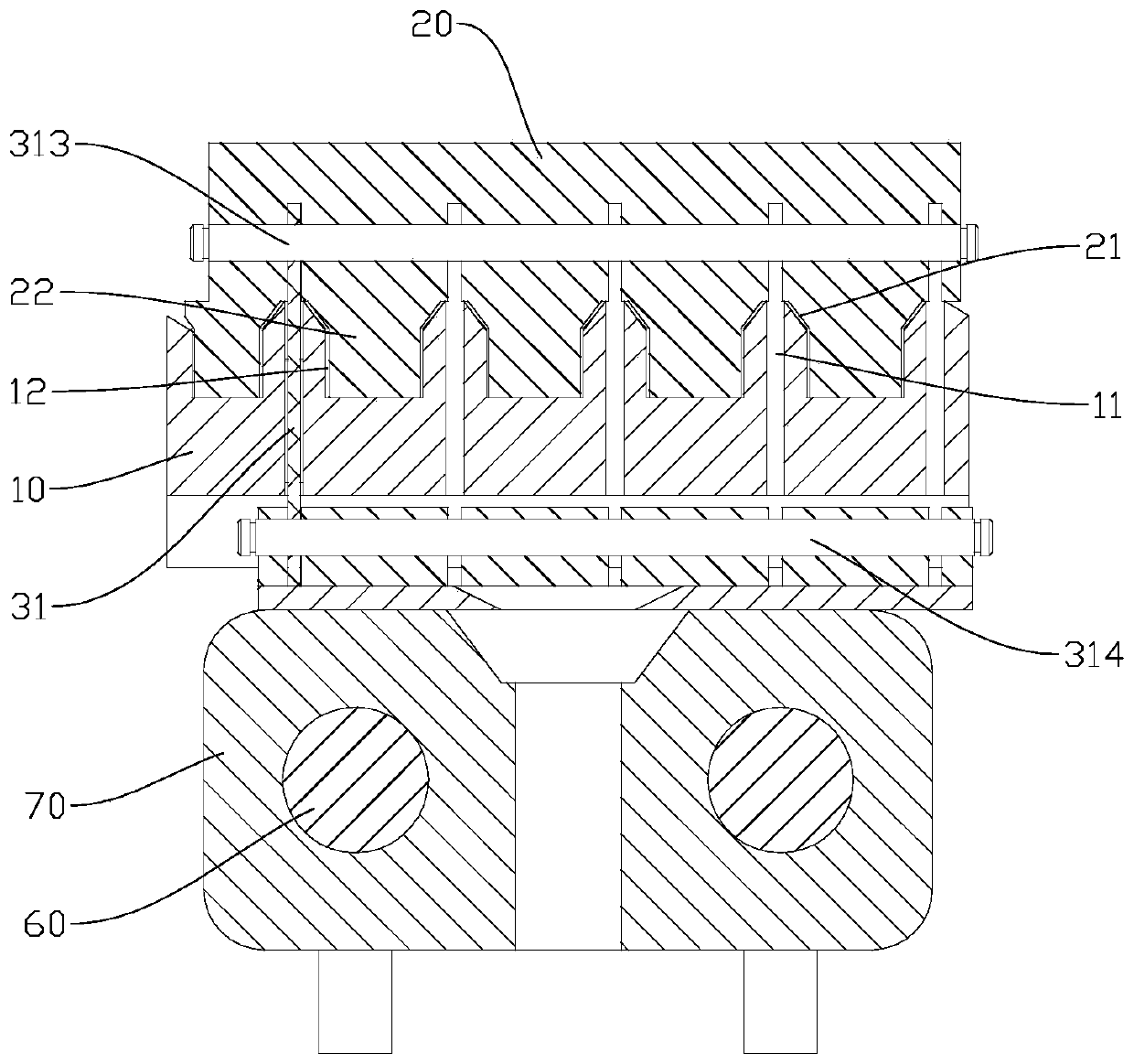

[0039] Such as Figure 1-2 As shown, the multifunctional string cutting device of this embodiment includes a knife seat 10 , a knife holder 20 , a cutter 30 , a first mold body 40 and a second mold body 50 . The knife rest 20 is slidably arranged on the knife seat 10, and the knife seat 10 is provided with a plurality of cutter slides 11 side by side along the moving direction of the cutter 30, and the cutter 30 is arranged in the cutter slide 11, and the rear of the cutter 30 The end is connected with the knife rest 20; under the action of the knife rest 20, the cutter 30 can move back and forth in the cutter slideway 11.

[0040] A stick chute 12 is arranged between the adjacent cutter slideways 11, and the stick 120 is placed in the stick chute 12, and the knife rest 20 can move back and forth along the cutter slideway 11 and the stick chute 12 at the same time, thereby driving the stick 120 sports.

[0041] Below the knife rest 10, a rod 60 and a knife rest driving block...

Embodiment 2

[0056] Such as Figure 7 As shown, in this embodiment, the knife rest 20' is slidably arranged on the knife seat 10', and the knife rest 20' is provided with a knife rest push-pull rod 140 (140'), and the knife rest push-pull rod 140 (140') is connected with the knife The rack 20' can adopt but not limited to the following two connection methods:

[0057] ①The knife rest push-pull rod 140 is arranged on the rear end of the knife rest 20', and realizes the push and pull of the knife rest 20' from the rear end;

[0058] ②The knife rest push-pull rod 140' is arranged on the top of the knife rest 20', and realizes the push and pull of the knife rest 20' from the top.

[0059] The above two connection methods can be used alone or in combination.

[0060] The difference between the technical solution of the first embodiment and the second embodiment is that the driving modes of the tool rest 20 (20') of the two are different. It is driven by the tool post push-pull rod 140 (140')...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com