Environment-friendly thermal transfer printing film and preparation method thereof

A thermal transfer printing and printing film technology, which is applied in the direction of copying/marking methods, printing, printing devices, etc., can solve the problem of unsatisfactory mechanical strength, toughness and elasticity of the hot stamping layer, product quality that does not meet the technical requirements for environmental protection and safety, and non-reflective Delicate and exquisite decoration and other issues, to achieve the effect of simple and convenient production process, excellent washing resistance, and enhanced display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

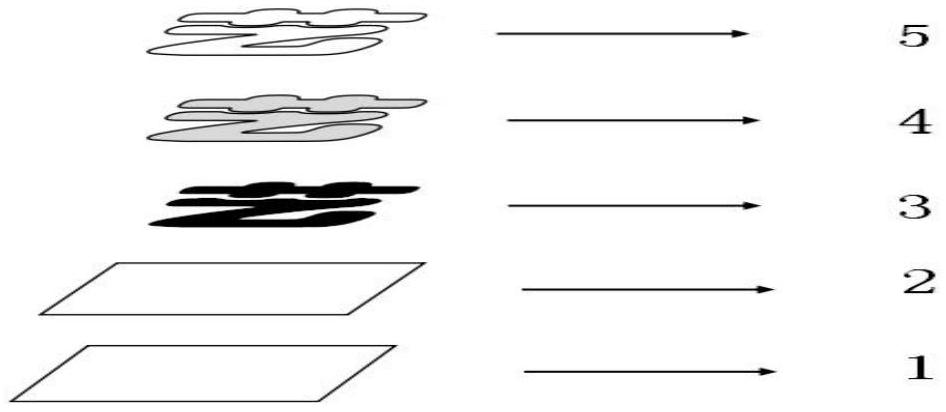

[0039] like figure 1 As shown, the present invention provides an environmentally friendly thermal transfer printing film, which includes a printing carrier 1 (quality requirements must meet the technical requirements of Q / FJQY 004-2019), a protective layer 2, a graphic layer 3, and a background from bottom to top. Layer 4 and hot melt adhesive layer 5, the protective layer 2 is formed by printing a polyurethane resin solution with a solid content of 24% on the surface of the printing carrier 1, and the graphic layer 3 is printed on the protective layer 2 by ink The background layer 4 is formed by printing background paste on the graphic layer 3, and the hot melt adhesive layer 5 is formed by coating hot melt adhesive on the background layer 4.

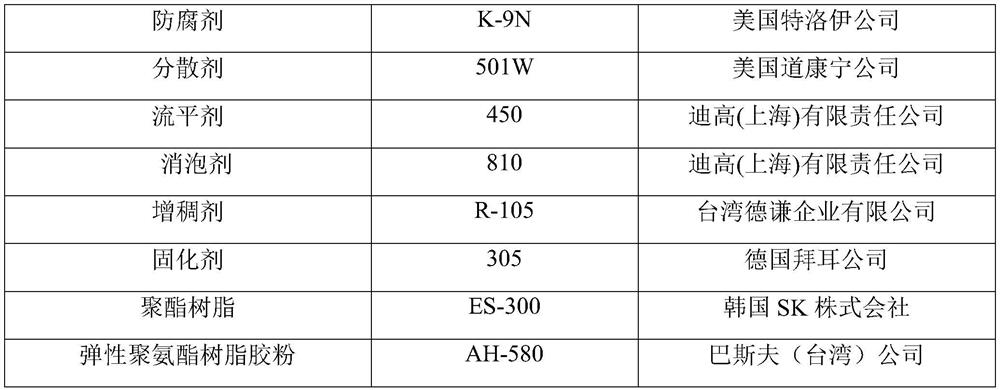

[0040] The background slurry includes the following components in parts by mass: 7 parts of deionized water above 15 megohm, 6 parts of propylene glycol, 1 part of water-based wax with a solid content of 20%, 0.07 part of preservative,...

Embodiment 2

[0050] like figure 1 As shown, the present invention provides an environmentally friendly thermal transfer printing film, which includes a printing carrier 1 (quality requirements must meet the technical requirements of Q / FJQY 004-2019), a protective layer 2, a graphic layer 3, and a background from bottom to top. Layer 4 and hot melt adhesive layer 5, the protective layer 2 is formed by printing a polyurethane resin solution with a solid content of 24% on the surface of the printing carrier 1, and the graphic layer 3 is printed on the protective layer 2 by ink The background layer 4 is formed by printing background paste on the graphic layer 3, and the hot melt adhesive layer 5 is formed by coating hot melt adhesive on the background layer 4.

[0051] The background slurry includes the following components in parts by mass: 5 parts of deionized water above 15 megohm, 4 parts of propylene glycol, 0.5 part of water-based wax with a solid content of 20%, 0.06 part of preservativ...

Embodiment 3

[0061] like figure 1 As shown, the present invention provides an environmentally friendly thermal transfer printing film, which includes a printing carrier 1 (quality requirements must meet the technical requirements of Q / FJQY 004-2019), a protective layer 2, a graphic layer 3, and a background from bottom to top. Layer 4 and hot melt adhesive layer 5, the protective layer 2 is formed by printing a polyurethane resin solution with a solid content of 24% on the surface of the printing carrier 1, and the graphic layer 3 is printed on the protective layer 2 by ink The background layer 4 is formed by printing background paste on the graphic layer 3, and the hot melt adhesive layer 5 is formed by coating hot melt adhesive on the background layer 4.

[0062] The background slurry includes the following components in parts by mass: 9 parts of deionized water above 15 megohms, 8 parts of propylene glycol, 1.5 parts of water-based wax with a solid content of 20%, 0.07 parts of preserva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com