Automatic adhesive removing device

An automatic, sliding installation technology, applied in the field of glue wiping, can solve the problems of hard to clean glue, small wiping range, low glue wiping efficiency, etc., and achieve the effect of energy saving, glue removal liquid saving and good glue removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

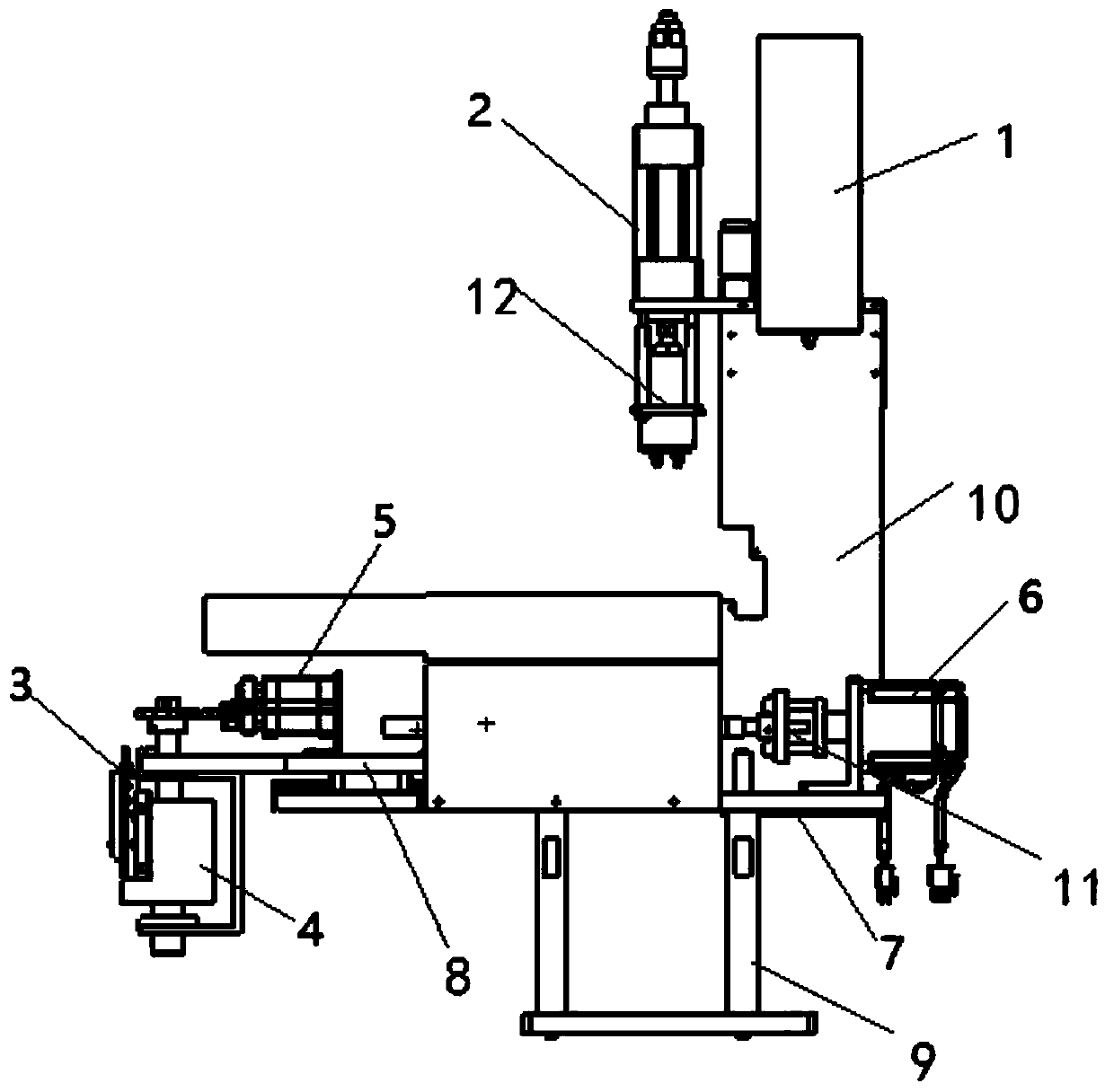

[0038] Embodiment: a kind of automatic deglue device, as figure 1 As shown, it includes a base frame 9, a quantitative cylinder 2 for glue removal, a quantitative cup 12, a temporary storage tank 1 for glue removal, a glue removal assembly, a guide mechanism for the glue removal assembly, an electrical control module and a power supply unit. The electrical control modules are respectively Connect the degumming solution quantitative cylinder 2, the degumming solution temporary storage tank 1, the degumming component, the degumming component guiding mechanism, the power supply unit provides power for the device, and the quantitative cup 12 and the degumming component pass through A glue removal channel is connected, and the power of the guide mechanism of the glue removal assembly is output to the glue removal assembly,

[0039]The top of the underframe 9 is fixed with a base plate 7, the base plate 7 is fixed with a mounting frame 10, and the glue removal temporary storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com