Knob type yarn tension regulator

A technology of yarn tension and tension adjustment, applied in the direction of thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problem of large loss of iron wire and iron hook, time-consuming adjustment, and falling of iron wire and iron hook. and other problems, to achieve the effect of improving production efficiency, large span of yarn thickness and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

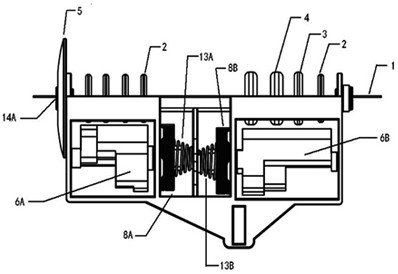

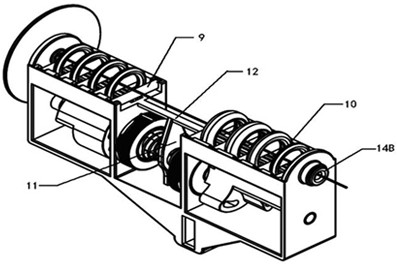

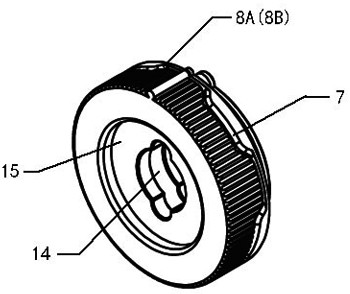

[0027] Such as figure 1 As shown, a tension disc 5 is set at the yarn entrance. The function of the tension disc 5 is to straighten the yarn before the yarn 1 enters the knob-type yarn tension regulator, so as to prevent the yarn 1 from catching the knob-type yarn tension regulator when twisted. Parts of the yarn tension regulator cause the problem of yarn tightness; yarn 1 enters the knob-type yarn tension regulator from the magnetic eye 14A in the middle of the tension disc 5, and then passes through the first set of tension pressure rings. The pressure ring is composed of 4 tension pressure rings 2 2 with the same weight. Whether these 4 tension pressure rings 2 have a positive pressure effect on the yarn 1 depends on the position of the corresponding cam upper edge of the cam group 6A; the yarn 1 wears After passing through the first group of ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com