Glass panel with high-fidelity imitation ceramic effect, and preparation method thereof

A glass panel, fidelity technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of low production cost and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

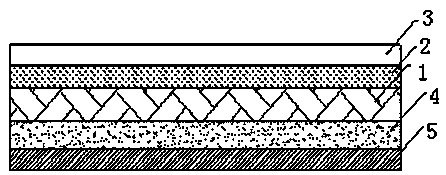

[0025] Embodiment 1~3 the glass panel of high-fidelity imitation pottery effect, as figure 1 As shown, a toughened glass panel 1 is included, and a base color high-temperature colored glaze layer 2 and a layered high-temperature colored glaze layer 3 are sequentially arranged on the upper surface of the toughened glass panel 1 from bottom to top, and on the lower surface of the toughened glass panel 1 There are primer ink layer 4 and dyne ink layer 5 arranged in sequence from top to bottom; among them, the thickness of tempered glass panel 1 is 0.3mm-8mm, and the thickness of base color high-temperature colored glaze layer 2 is >15µm, which has a sense of hierarchy. The thickness of the high-temperature colored glaze layer 3 is >50µm, the thickness of the primer ink layer 4 is 30µm-500µm, and the thickness of the dyne ink layer 5 is 50µm-500µm.

Embodiment 1

[0027] The preparation method of the glass panel with high fidelity imitating ceramic effect of this embodiment, the preparation method comprises the following steps:

[0028] Step 1: On the toughened glass panel 1 with a thickness of 0.3mm, uniformly coat a layer of base color high-temperature color glaze layer 2 with a thickness of 20um by silk screen printing, spraying, printing, roller coating or spin coating, and then dry it on Dry and solidify the glaze layer at a high temperature of 650°C;

[0029] Step 2: On the dried and solidified base color high-temperature glaze layer 2, evenly coat a layer of high-temperature glaze layer 3 with a thickness of 55um by silk screen printing, spraying, printing, roller coating or spin coating, and then pass The drying process is to dry at a temperature of 100°C, and then quench the fan to normal temperature to dry and solidify the glaze layer;

[0030] Step 3: The tempered glass panel 1 with the base color high-temperature glaze laye...

Embodiment 2

[0034] The preparation method of the glass panel with high fidelity imitating ceramic effect of this embodiment, the preparation method comprises the following steps:

[0035] Step 1: On the toughened glass panel with a thickness of 4mm, uniformly coat a layer of high-temperature color glaze layer with a thickness of 50um by silk screen printing, spraying, printing, roller coating or spin coating, and then dry it at 680°C Dry and solidify the glaze layer at high temperature;

[0036] Step 2: On the dried and cured base color high-temperature glaze layer, evenly coat a layer of high-temperature glaze layer with a thickness of 100um by silk screen printing, spraying, printing, roller coating or spin coating, and then dry The process is dried at a temperature of 200°C and then quenched by a fan to room temperature to dry and solidify the glaze layer;

[0037] Step 3: Put the tempered glass panel with the base color high-temperature glaze layer and the layered high-temperature glaz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com