Production process of jacquard fabric with petit point effect

A production process and technology for jacquard fabrics, applied in the direction of excavated fabrics, fabrics, through-hole fabrics, etc., can solve the problems of cumbersome process, limited weaving conditions, and difficulty in showing sieve holes, so as to enrich the form of expression, improve the yield, The effect of reducing the number of weft combinations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A production process of jacquard fabric with nano-yarn embroidery effect, the production process comprises the following steps: specification design, fabric structure design, and machine weaving.

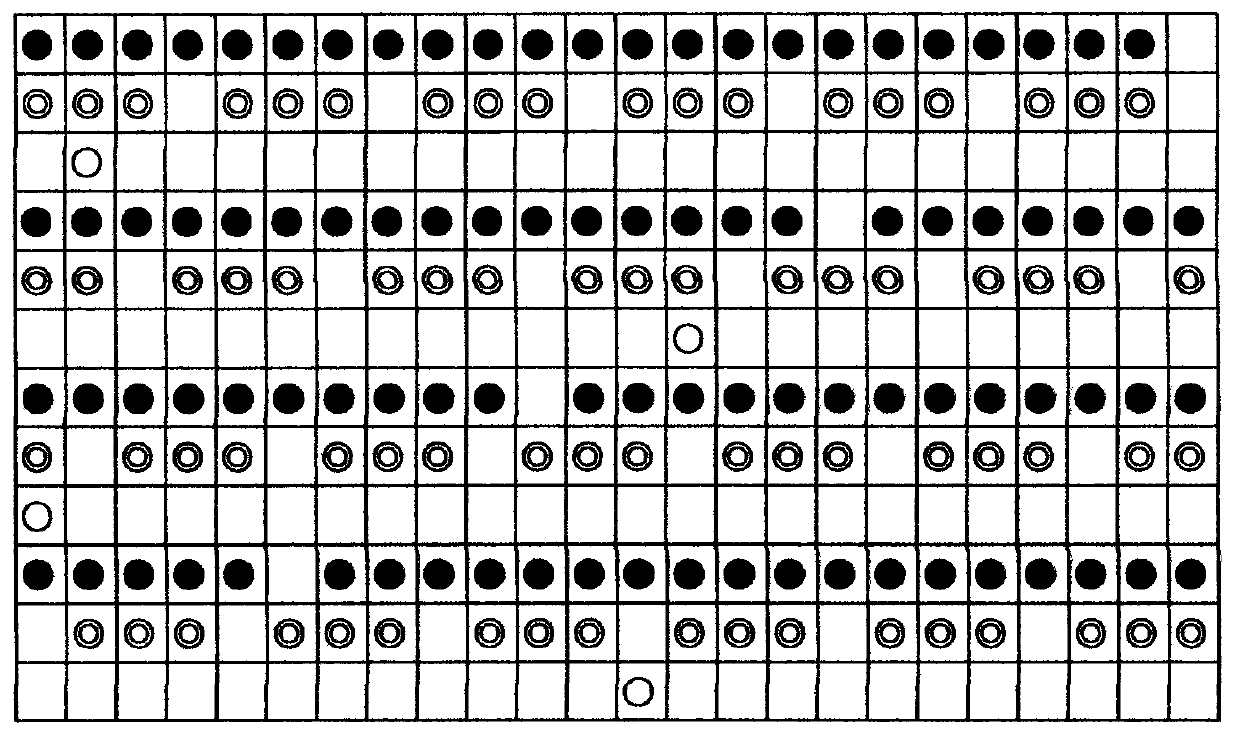

[0028] Specification design: The warp combination is composed of a large number of surface warp threads and a small number of inner layer warp threads. A weft, B weft and C weft form a weft combination to determine the inner width of the finished product, the finished warp and weft density and the effective number of warp threads.

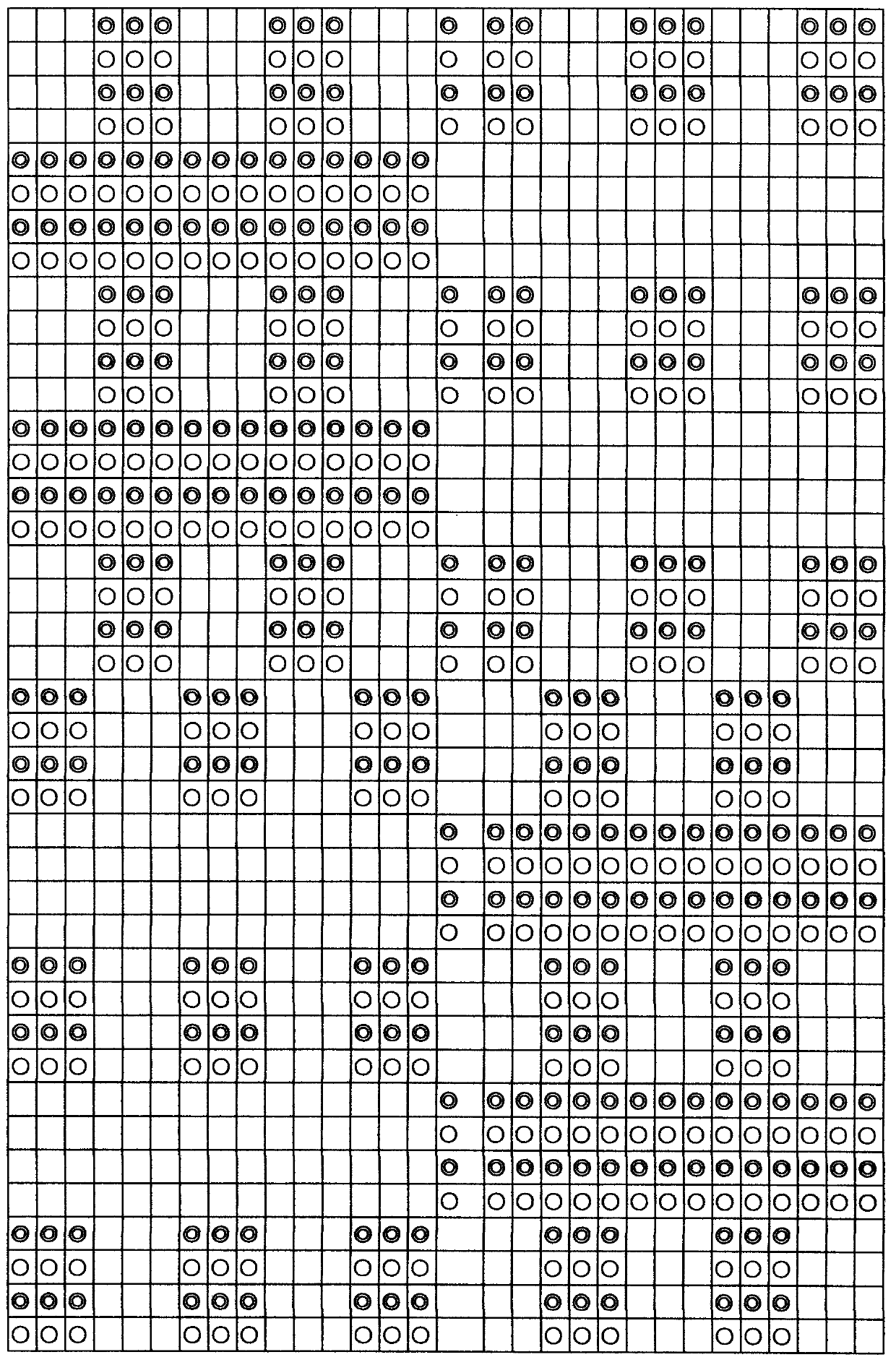

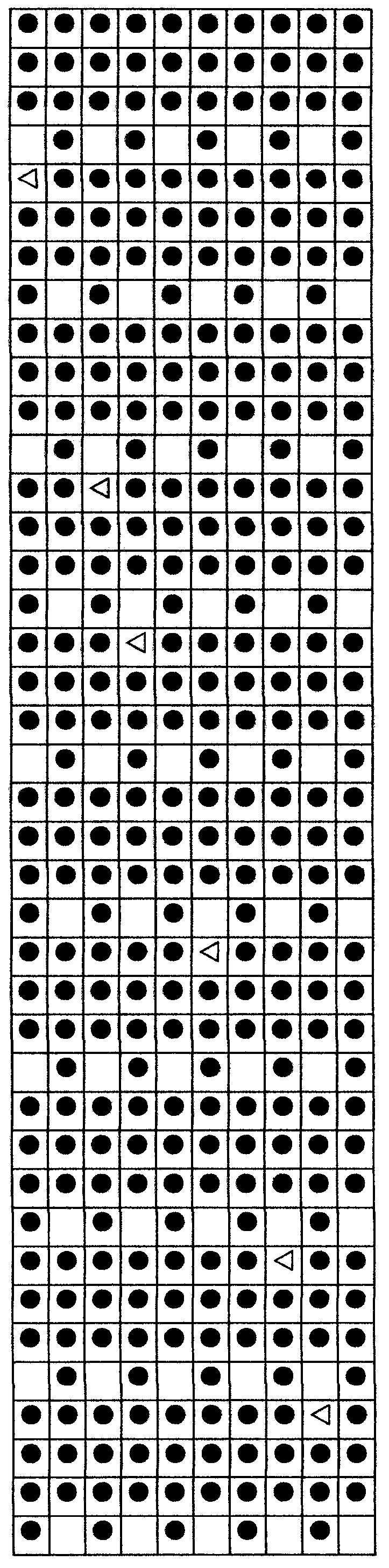

[0029] Weave Design: There are raised flower parts on the surface of the fabric. The flower part adopts heavy weft weave, and all warp threads are interwoven with A weft, B weft and C weft. 4, that is, the number of cycles of the three sets of wefts is controlled at 12.

[0030] In the ground where the fabric needs to form weaving yarn holes, the ground structure adopts a double-layer structure, the surface structure adopts a through-hole structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com