Noise-reducing conducting device of waste pyrolysis gasification furnace

A pyrolysis gasification and conduction device technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve problems such as easy generation of dioxin, uneven heating of garbage, injury to staff and surrounding residents, etc. Achieve good discharging effect, complete reaction and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

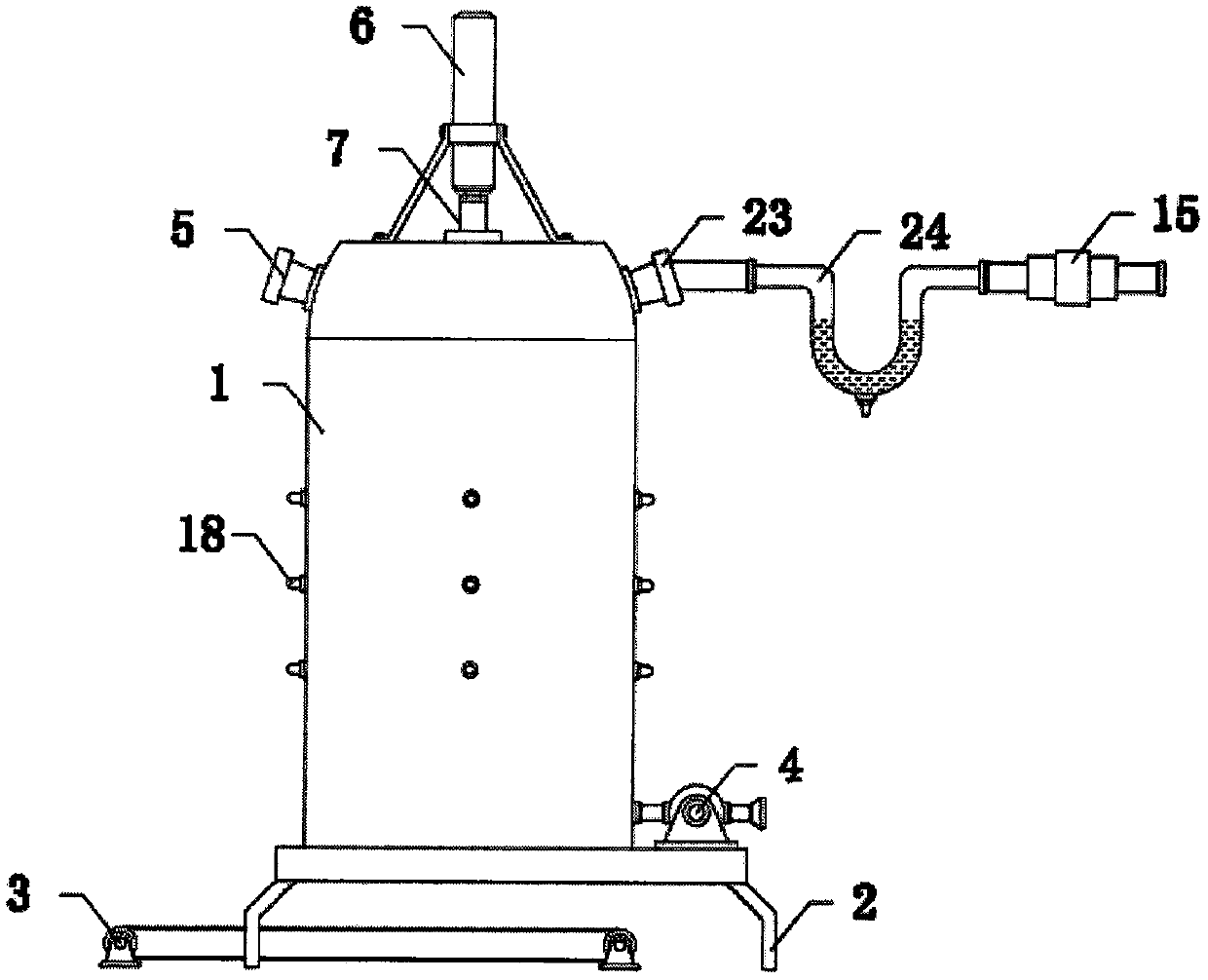

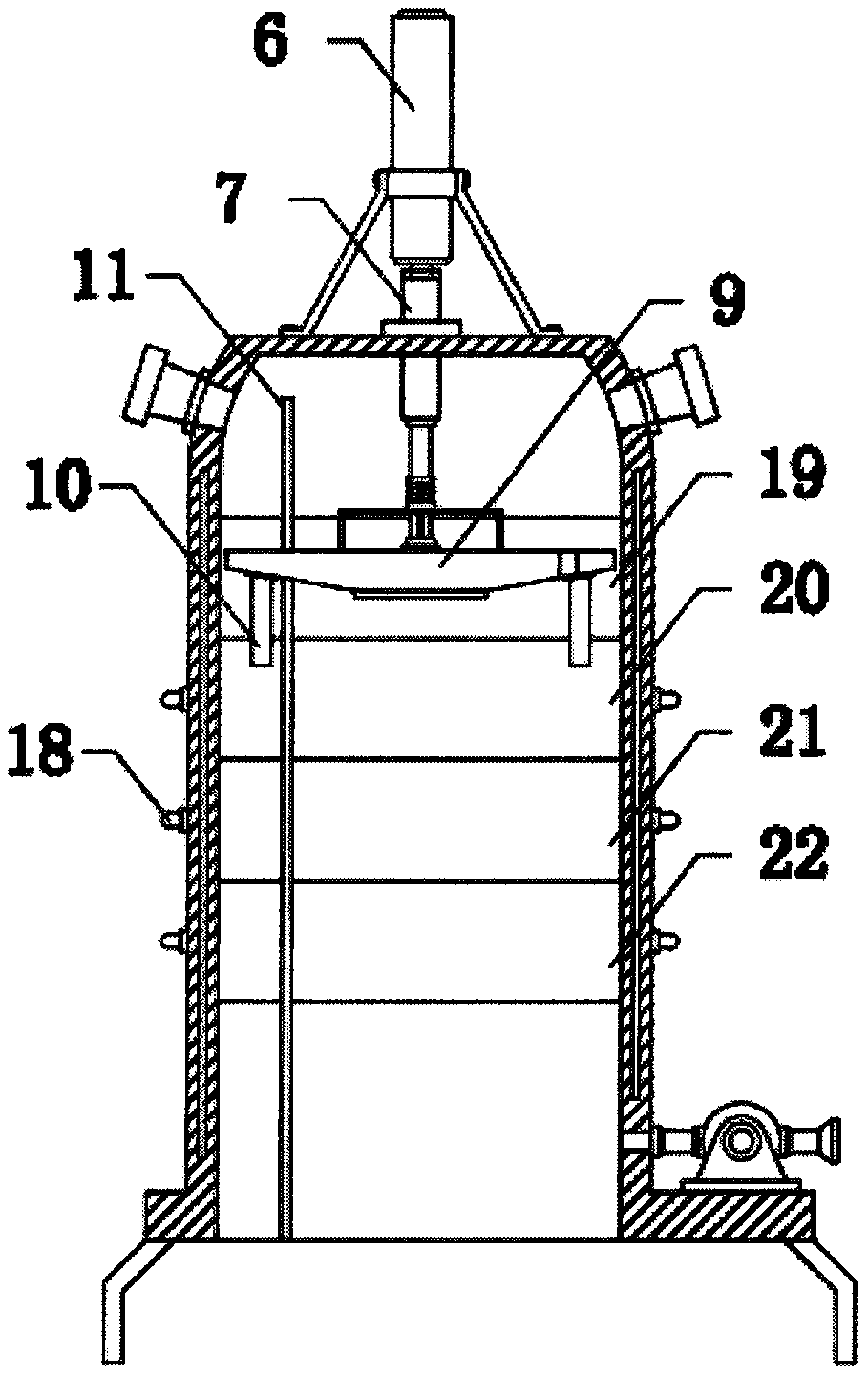

[0027] see Figure 1-4 , the present invention provides a technical solution: an antibacterial conduction device for a garbage pyrolysis gasifier, comprising a furnace body 1, a support 2 arranged at the bottom of the furnace body 1, and a feeding port is provided at the upper end of the side wall of the furnace body 1 5 and the air outlet 23, the bottom end of the side wall of the body of heater 1 is equipped with an air intake fan 4, the air outlet of the air inlet fan 4 communicates with the inner cavity of the body of heater 1, and the charging port 5 is used to inject garbage to be processed in the body of heater 1 , the gas outlet 23 is used to discharge the gas that can be reused after the reaction, and the air intake fan 4 drives the airflow to provide the oxygen required for the reaction in the furnace body 1;

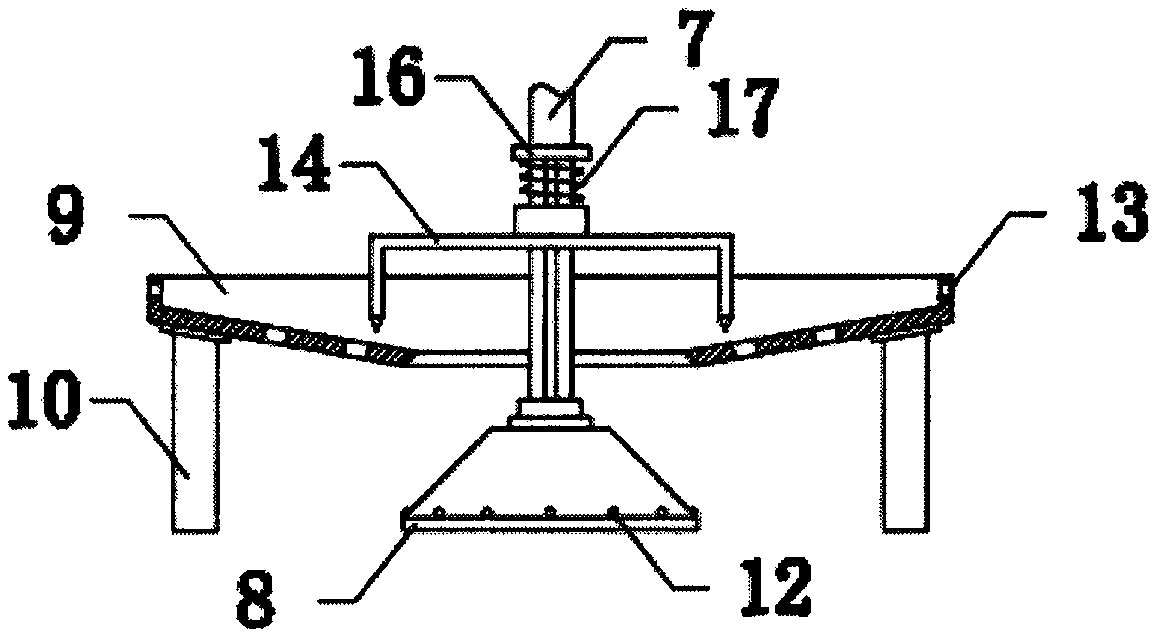

[0028] The upper end of the furnace body 1 is equipped with a rotating motor 6 through a motor base, and the bottom end of the rotor shaft of the rotating mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com