Patents

Literature

76results about How to "Improve nesting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

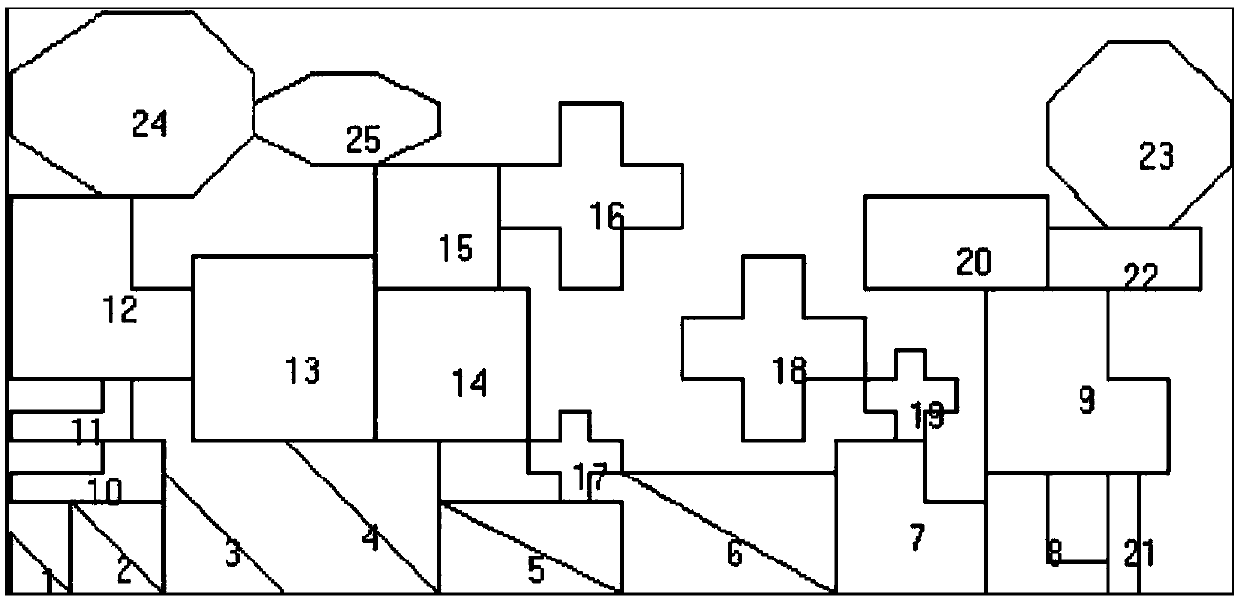

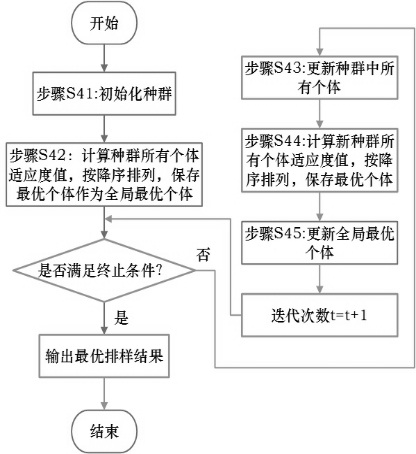

Irregular part stock layout method based on multi-factor particle swarm algorithm

ActiveCN105488562AReduce complexityReduce the numberBiological modelsLocal optimumPhases of clinical research

The invention provides an irregular part stock layout method based on a multi-factor particle swarm algorithm. The method comprises the following steps of 1, performing preprocessing on a sample sheet, performing sorting merging on some sample sheets, and finally obtaining sample sheets requiring the stock layout; 2, extracting contour points of a material and feature points of the sample sheets, and judging the overlapping relationship of the sample sheets and the material by a downwards sinking left and right dispersed stock layout algorithm; 3, performing an improved PSO algorithm searching process. A plurality of factors are added into the PSO algorithm; the factors are continuously changed according to a certain rule, so that the particle swarm has higher global and local searching capability in each stage, and the local optimum is avoided; and when the stock layout effect meets the requirements or the number of iteration times reaches the set value, the global optimum stock layout scheme is used as the final stock layout scheme. The irregular part stock layout method based on the multi-factor particle swarm algorithm provided by the invention has the advantages of high global searching capability, high local searching capability, good convergence property and good stock layout effect.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH

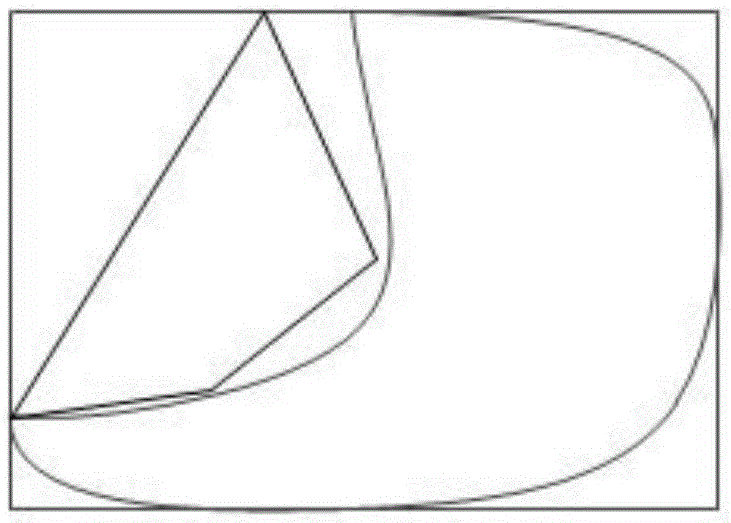

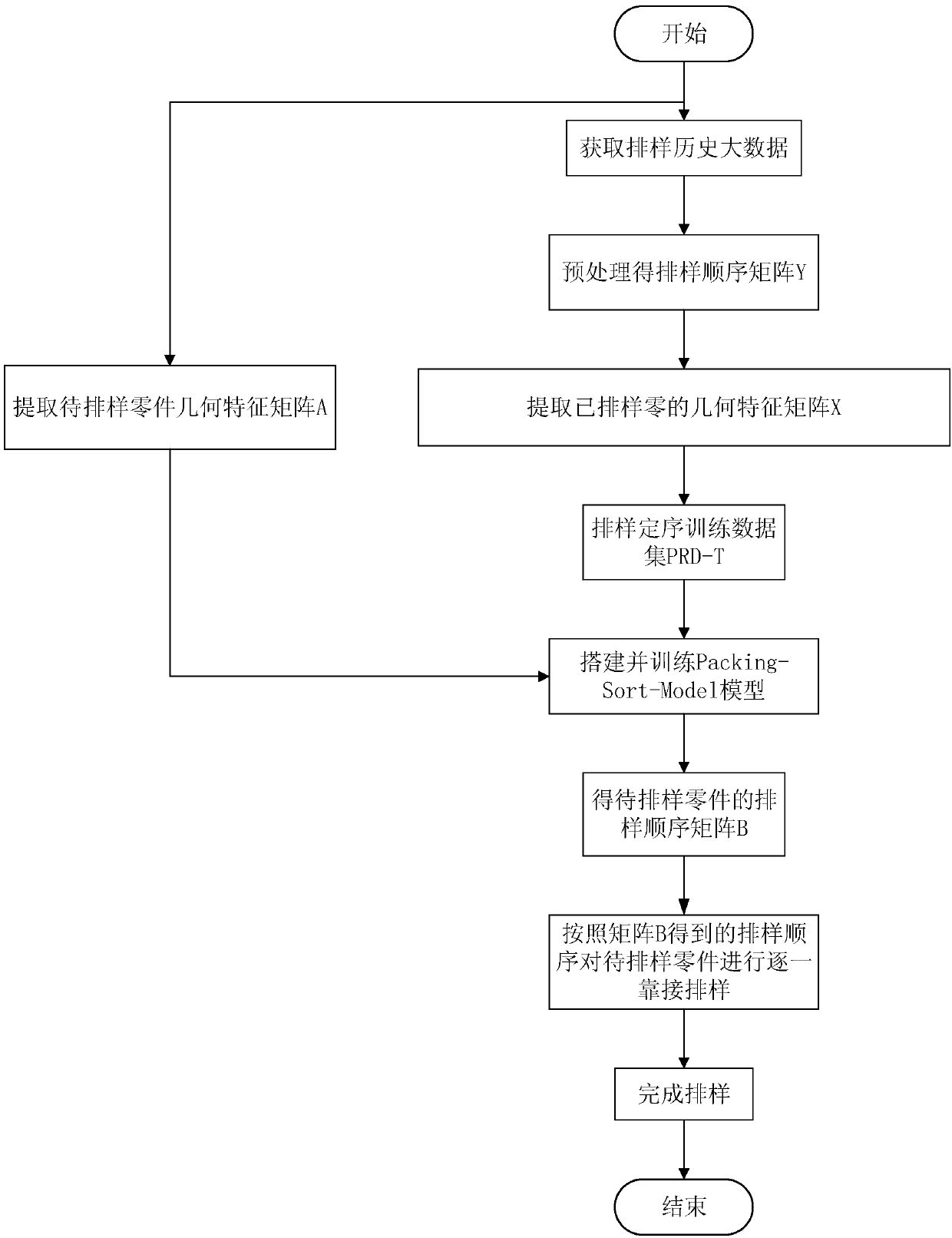

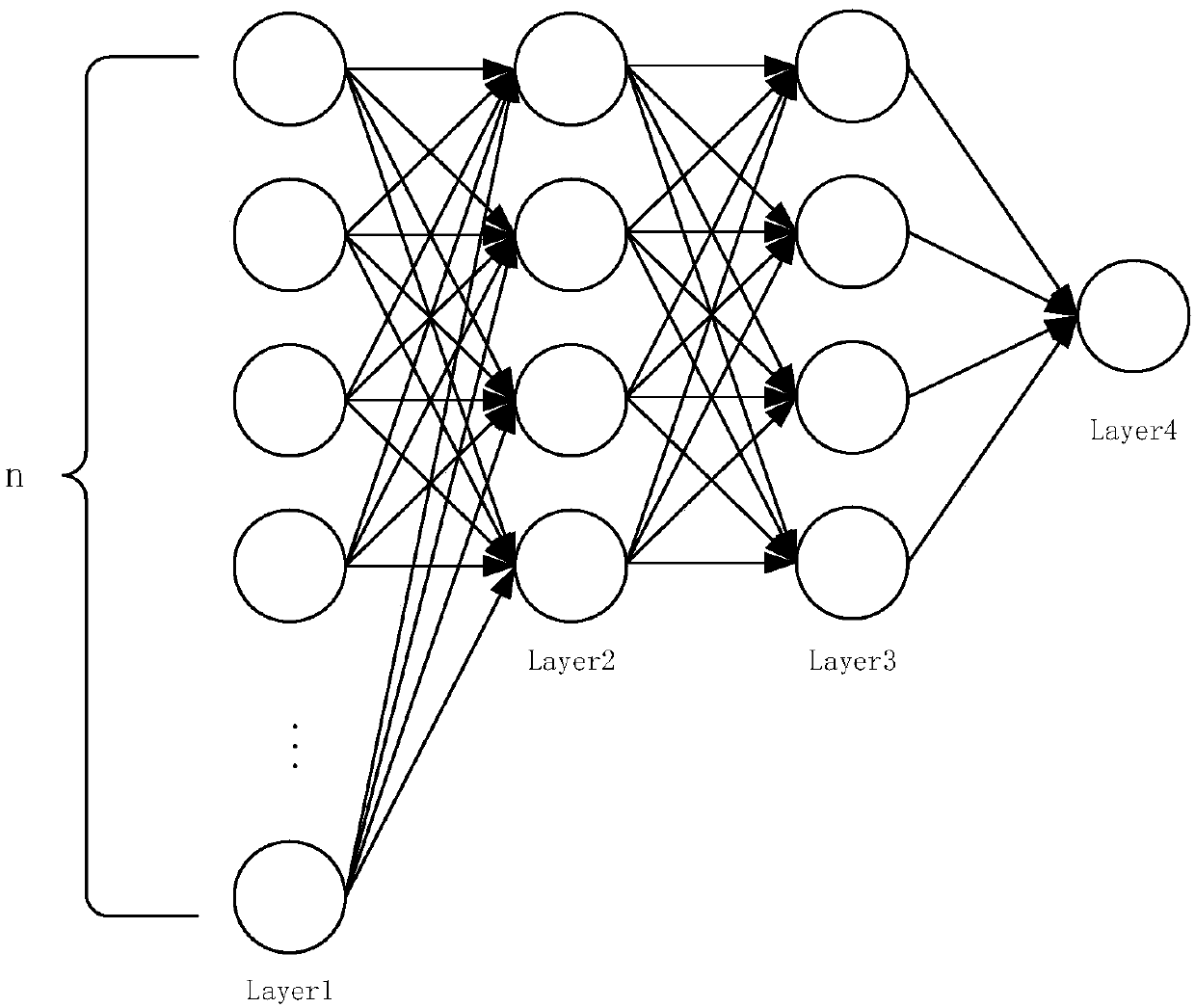

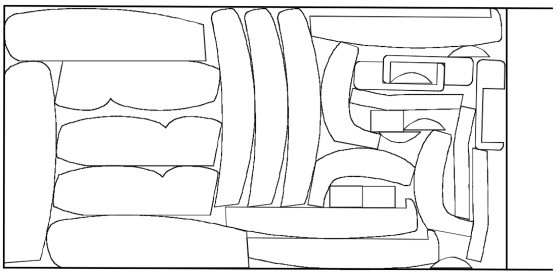

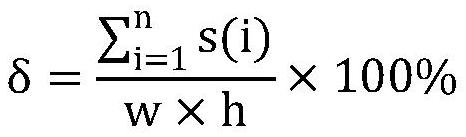

Two-dimensional contour packing sequencing method based on depth learning

ActiveCN109543899AImprove nesting effectImprove efficiencyForecastingNeural architecturesData setAlgorithm

The invention discloses a two-dimensional contour layout and sequencing method based on deep learning, which comprises: acquiring the layout history big data and pre-processing, and calibrating all the arranged parts in the historical data to obtain a layout order matrix Y. Extract the geometric features of each sampled part to obtain the geometric feature matrix X; sorting out the sampled sequence data set PRD-T; building the deep learning model Packing-Sort-Model; inputting the PRD-T data set, and traiiung to obtain, wherein The model Packing-Sort-Model that outputs the order of the parts tobe sampled; extracting the geometric features of the parts to be sampled, obtaining the geometric feature matrix A of the parts to be sampled; inputting the geometric feature matrix of the parts to be placed into the trained In the deep learning model; calculate the layout order matrix B of the parts to be placed; perform the nesting one by one according to the layout order, and complete the layout. The invention can realize the ordering of the parts to be discharged during the layout process, and has good layout effect and high efficiency.

Owner:YANSHAN UNIV

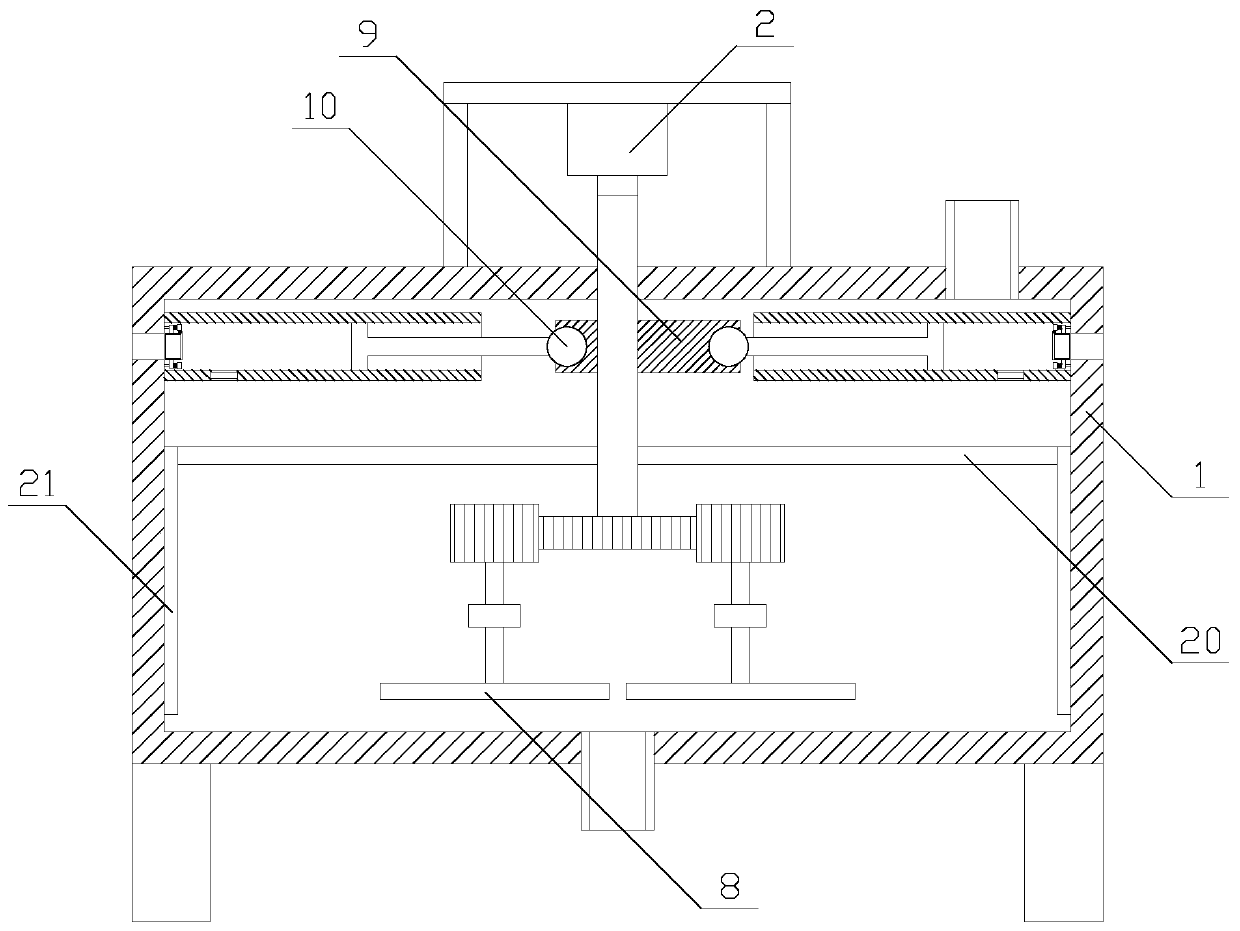

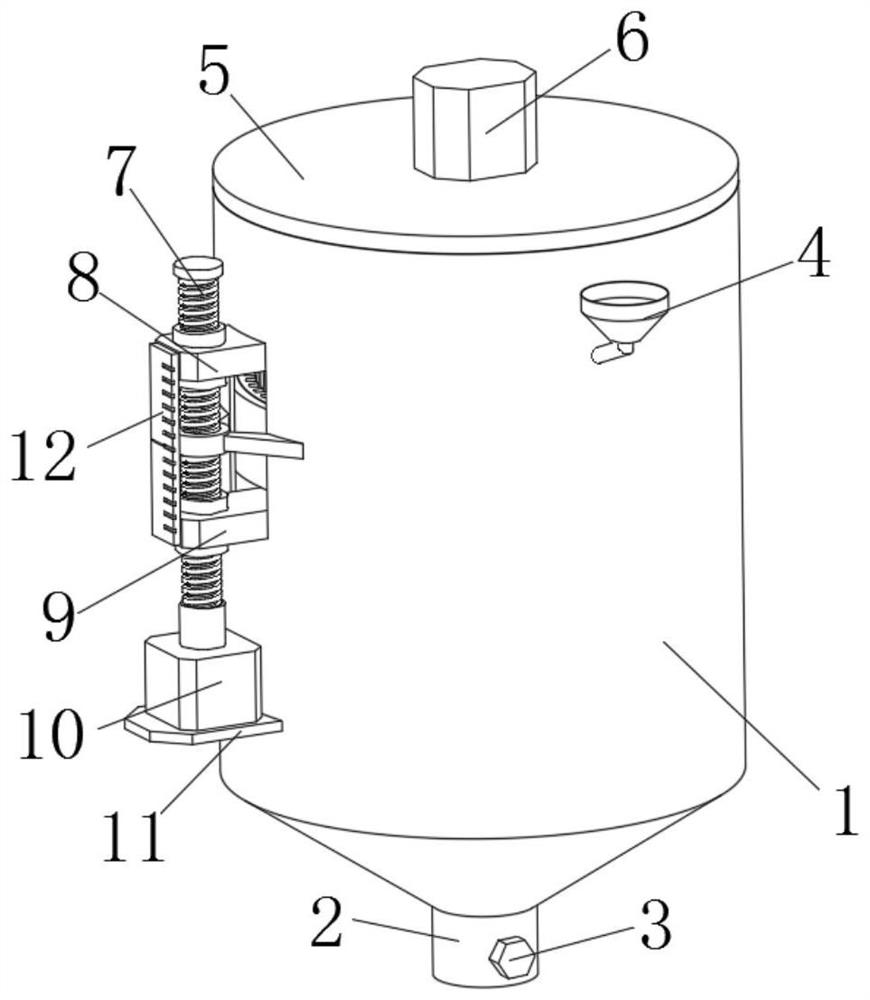

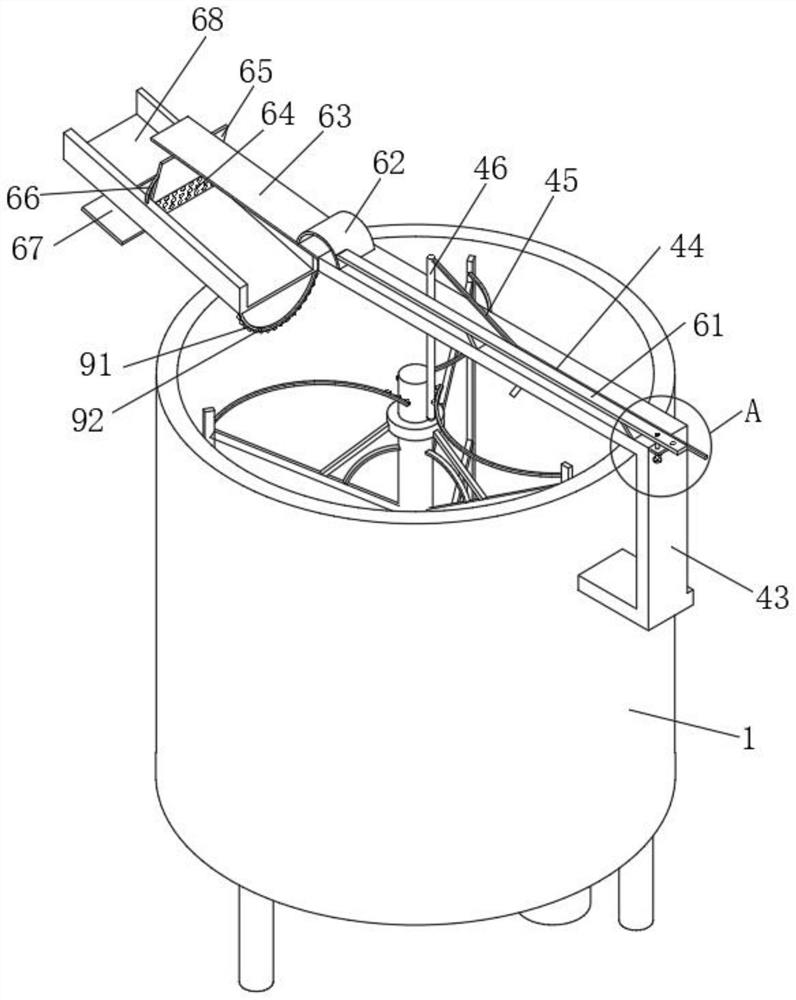

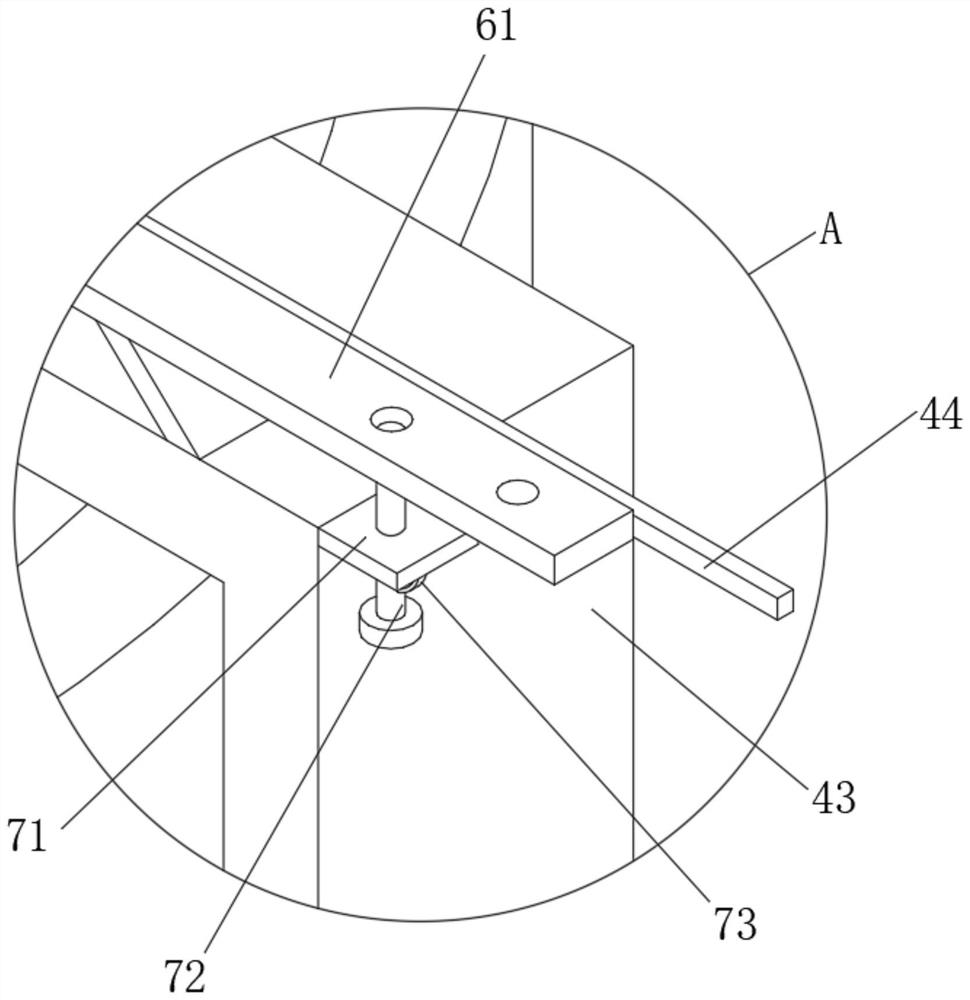

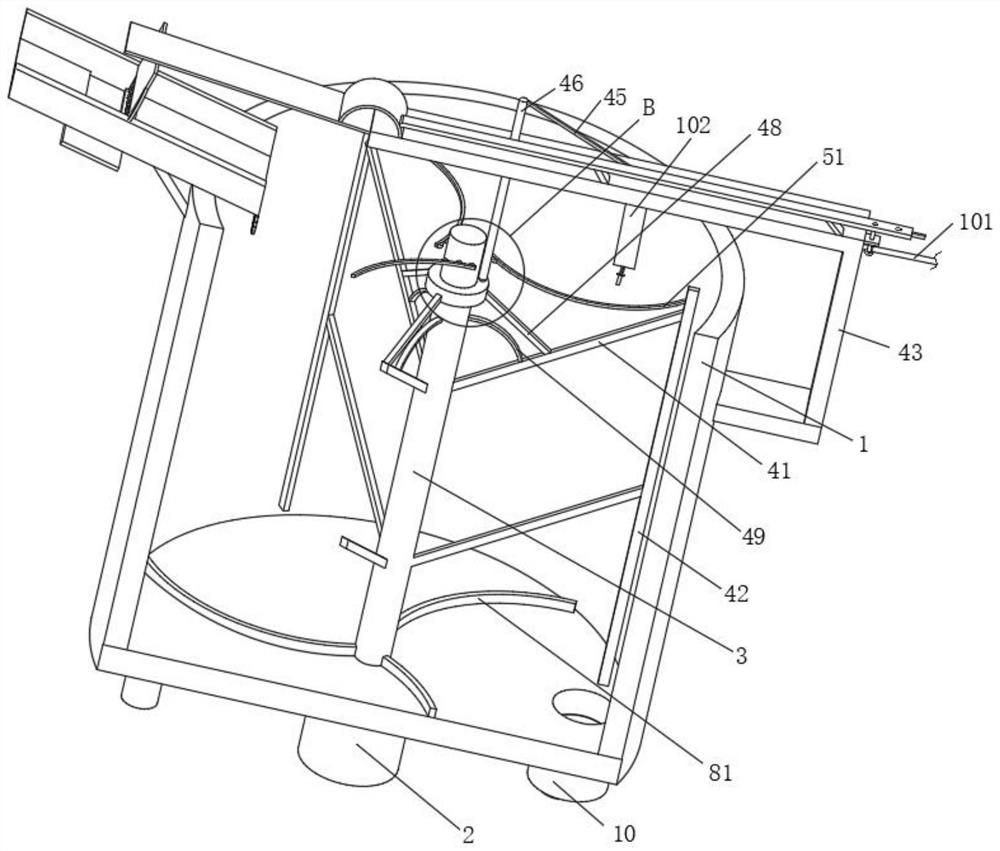

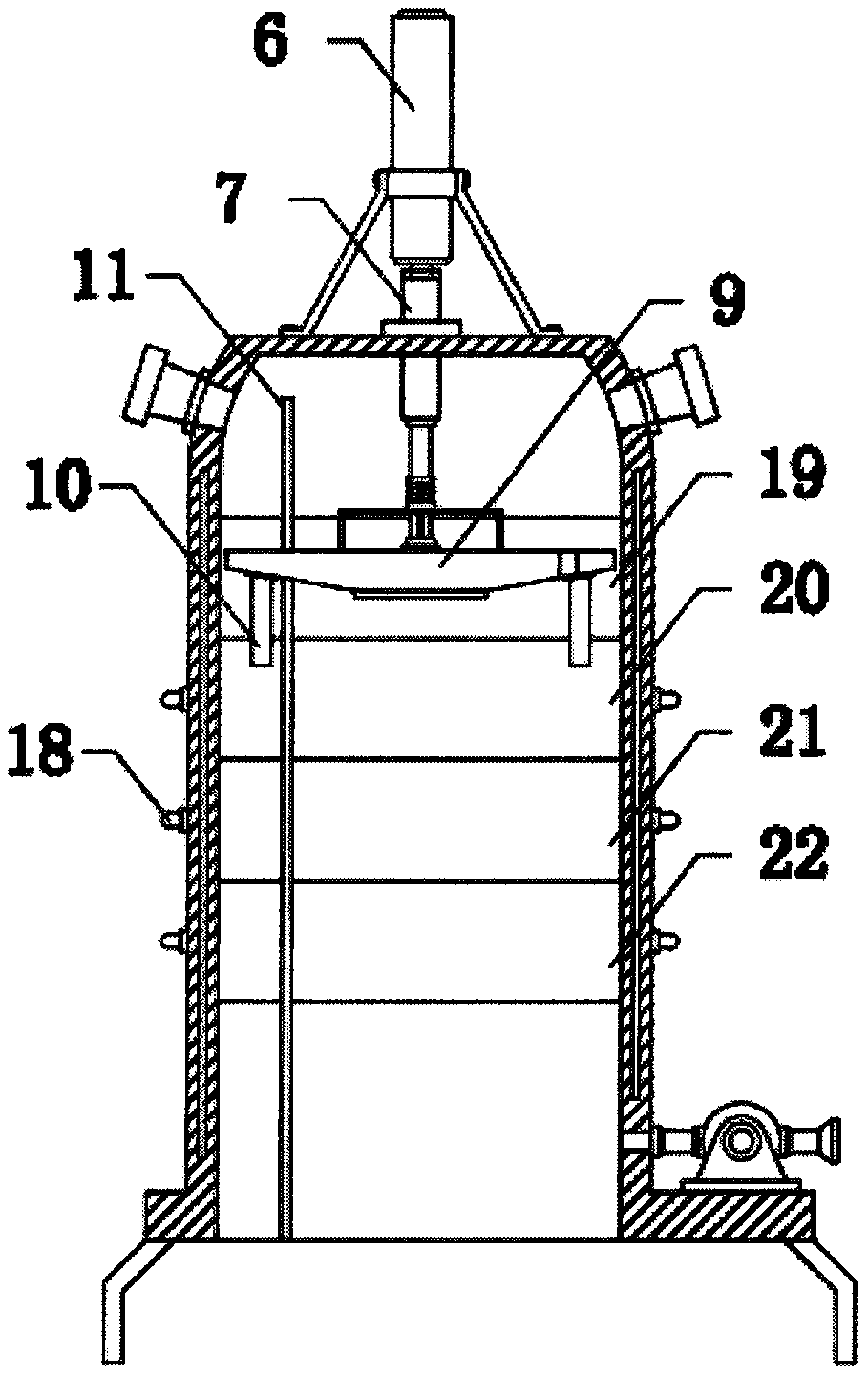

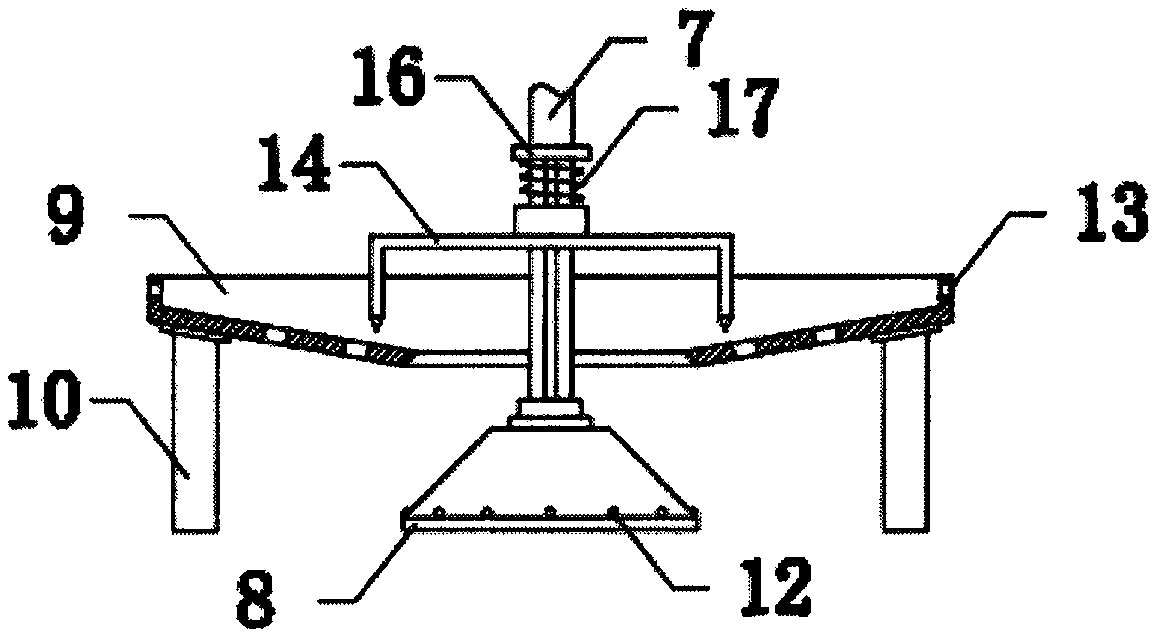

Fermentation equipment with good stirring effect for producing yogurt

InactiveCN110100888AImprove mixing uniformityIngenious structureMilk preparationBiochemical engineeringDrive shaft

The invention relates to fermentation equipment with a good stirring effect for producing yogurt. The fermentation equipment comprises a main equipment body, a driving motor and a transmission shaft;the main equipment body is in a cylindrical shape, the transmission shaft is coaxial with the main equipment body, a through hole is formed in the top of the main equipment body, and the transmissionshaft penetrates through the through hole, then slides and is hermetically connected with the through hole; the driving motor is arranged at the top of the main equipment body and is in transmission connection with the transmission shaft, the main equipment body is internally provided with a stirring mechanism and an auxiliary mechanism, the stirring mechanism is connected with the transmission shaft and comprises a driving gear and two stirring assemblies, and the driving gear is installed on the transmission shaft and located between the two stirring assemblies. The fermentation equipment with the good stirring effect for producing the yogurt has the advantages that the stirring function is achieved through the stirring mechanism, and moreover, the discharging effect is improved throughthe auxiliary mechanism.

Owner:武桂英

Two-dimensional irregular part layout method based on optimal foraging algorithm

PendingCN111985012AQuality assuranceImprove solution efficiencyGeometric CADArtificial lifeTheoretical computer scienceGlobal optimization

The invention relates to a two-dimensional irregular part layout method based on an optimal foraging algorithm. The method comprises the steps of S1, conducting mathematical description on the layoutproblem of two-dimensional irregular parts; S2, establishing constraint conditions needing to be met in the layout optimization process; S3, determining a target to be optimized, and establishing a corresponding two-dimensional irregular part layout target optimization function; and S4, performing global optimization search on the arrangement sequence and the rotation angle of the parts based on an optimal foraging algorithm, determining the optimal arrangement sequence and the rotation angle of the parts, and outputting an optimal layout result. The two-dimensional irregular part layout method based on the optimal foraging algorithm is suitable for layout of convex and concave polygonal parts and complex parts with holes. Compared with a two-dimensional irregular layout problem solving method based on a traditional heuristic algorithm, the method is high in layout efficiency, good in robustness and high in material utilization rate.

Owner:FUZHOU UNIV

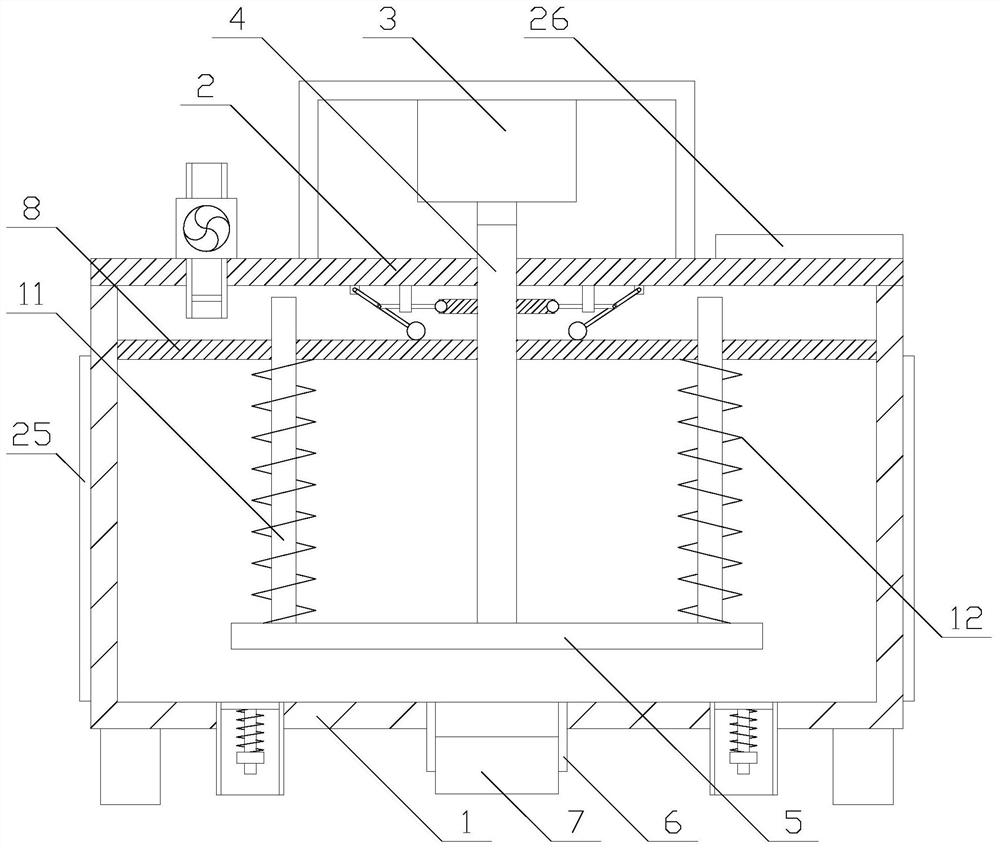

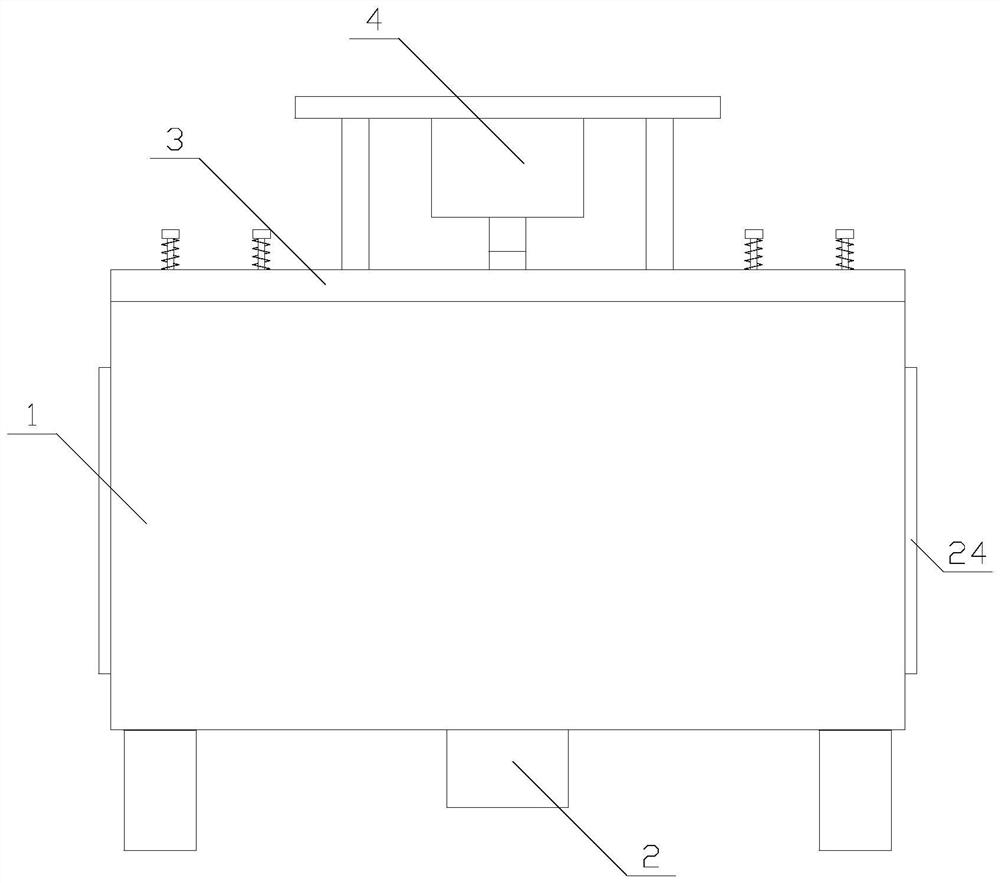

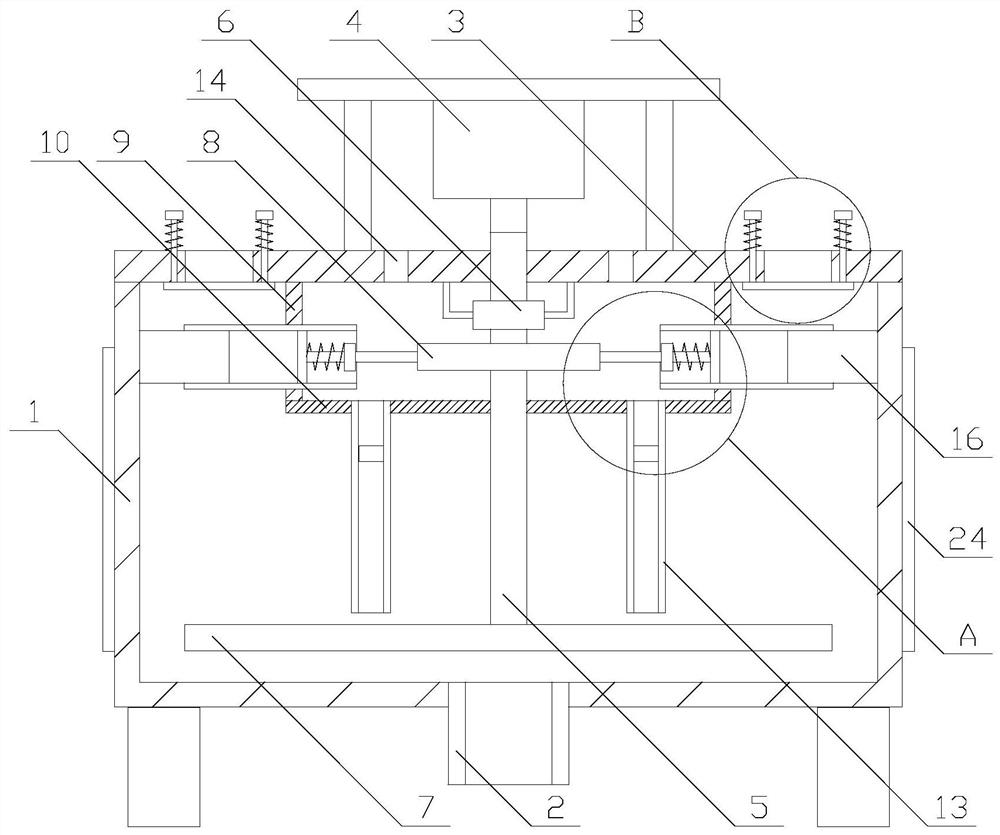

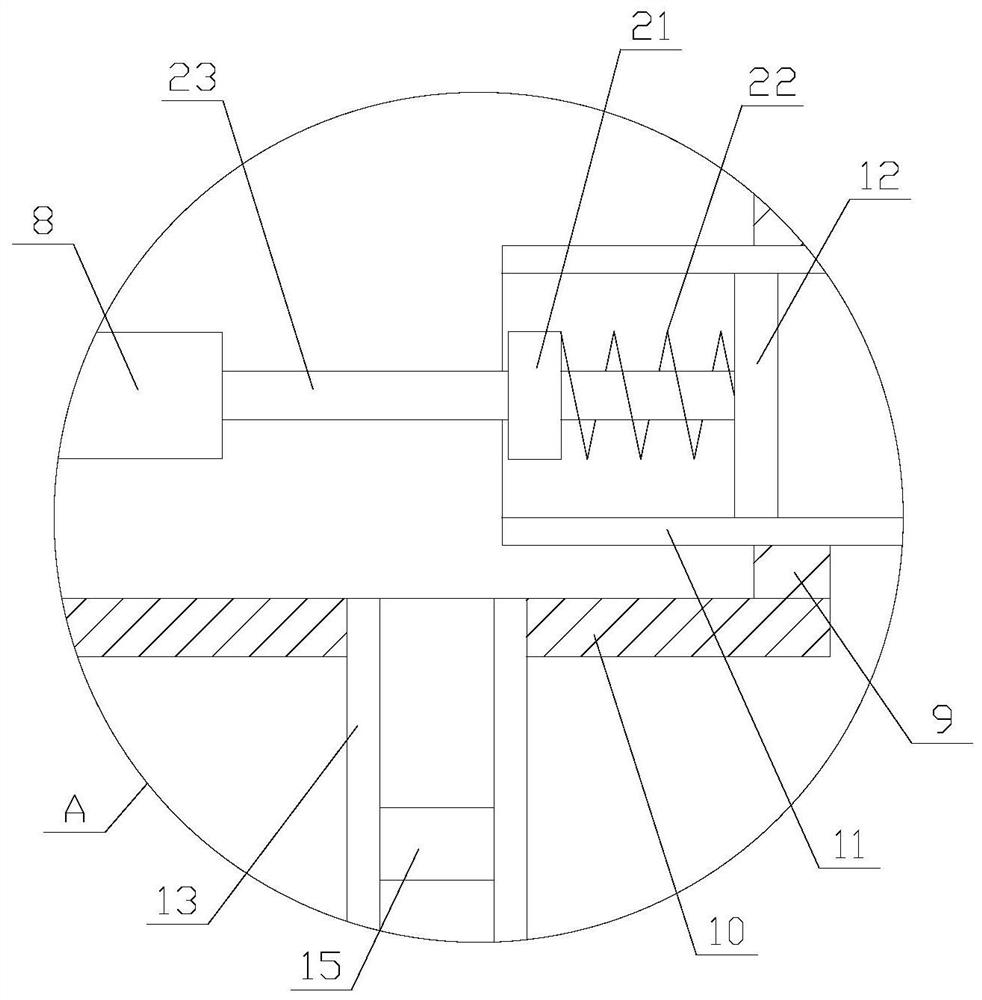

Constructional engineering equipment beneficial for discharging

InactiveCN112140335AAvoid stickingImprove nesting effectDischarging apparatusHollow article cleaningElectric machineryDrive motor

The invention relates to constructional engineering equipment beneficial for discharging. The constructional engineering equipment comprises a stirring barrel, a sealing cover, a driving motor, a transmission shaft, a stirring rod, a discharging pipe and a sealing plug, wherein the stirring barrel is cylindrical, the stirring barrel is vertically arranged, the top of the stirring barrel is provided with an opening, and the sealing cover covers the top of the stirring barrel and is in sealing connection with the stirring barrel. The discharging pipe and the transmission shaft are respectively coaxial with the stirring barrel, the top end of the discharging pipe is fixed at the bottom of the stirring barrel and communicates with the stirring barrel, the sealing plug is inserted into the bottom end of the discharging pipe, the sealing plug is matched with the discharging pipe and is in sealing connection with the discharging pipe, and an auxiliary mechanism and a connecting mechanism arearranged on the stirring barrel. According to the constructional engineering equipment beneficial for discharging, the discharging effect is improved through the auxiliary structure, concrete is prevented from adhering to the inner wall of the stirring barrel, and in addition, the stirring uniformity is improved through the connecting mechanism.

Owner:广州市索德士皮具皮革贸易有限公司

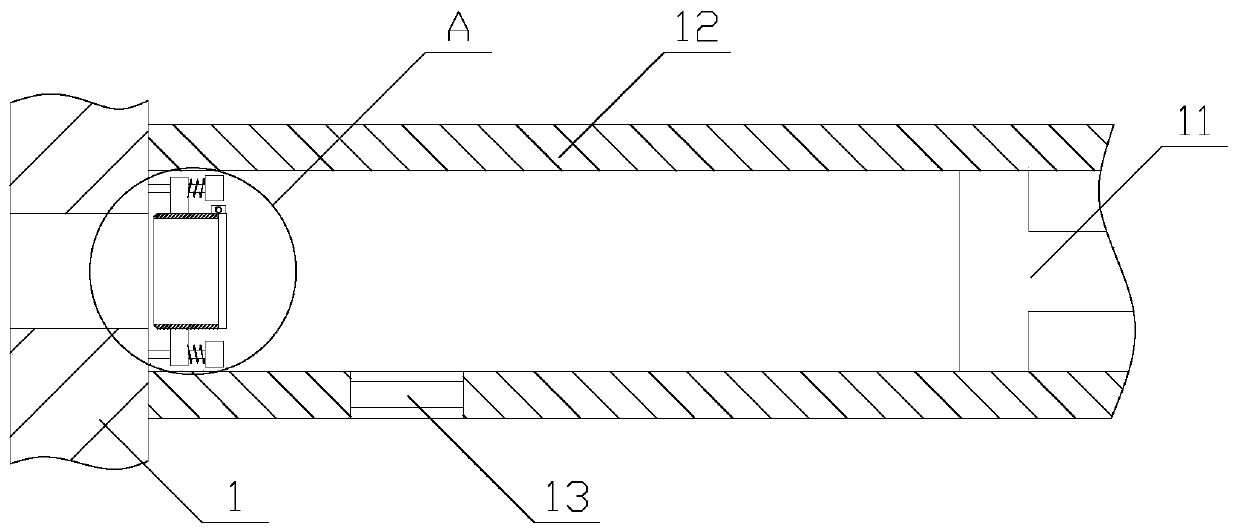

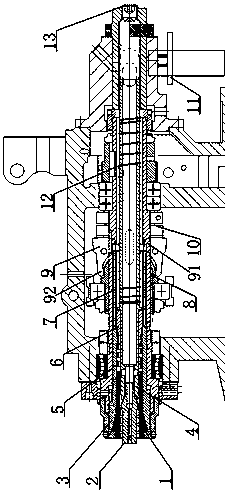

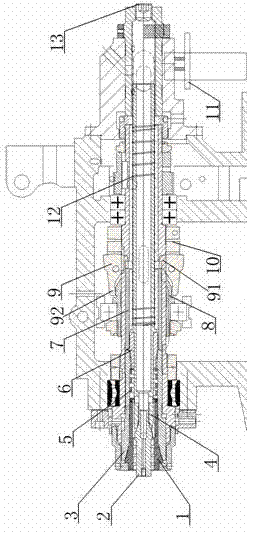

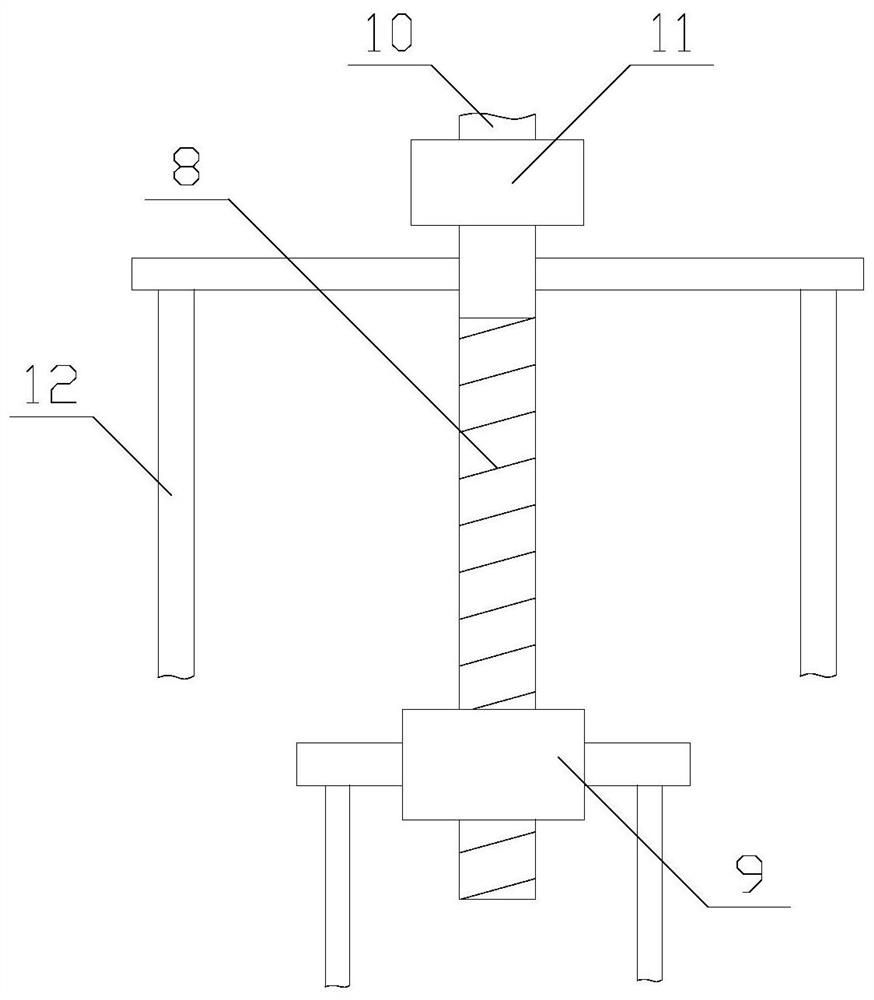

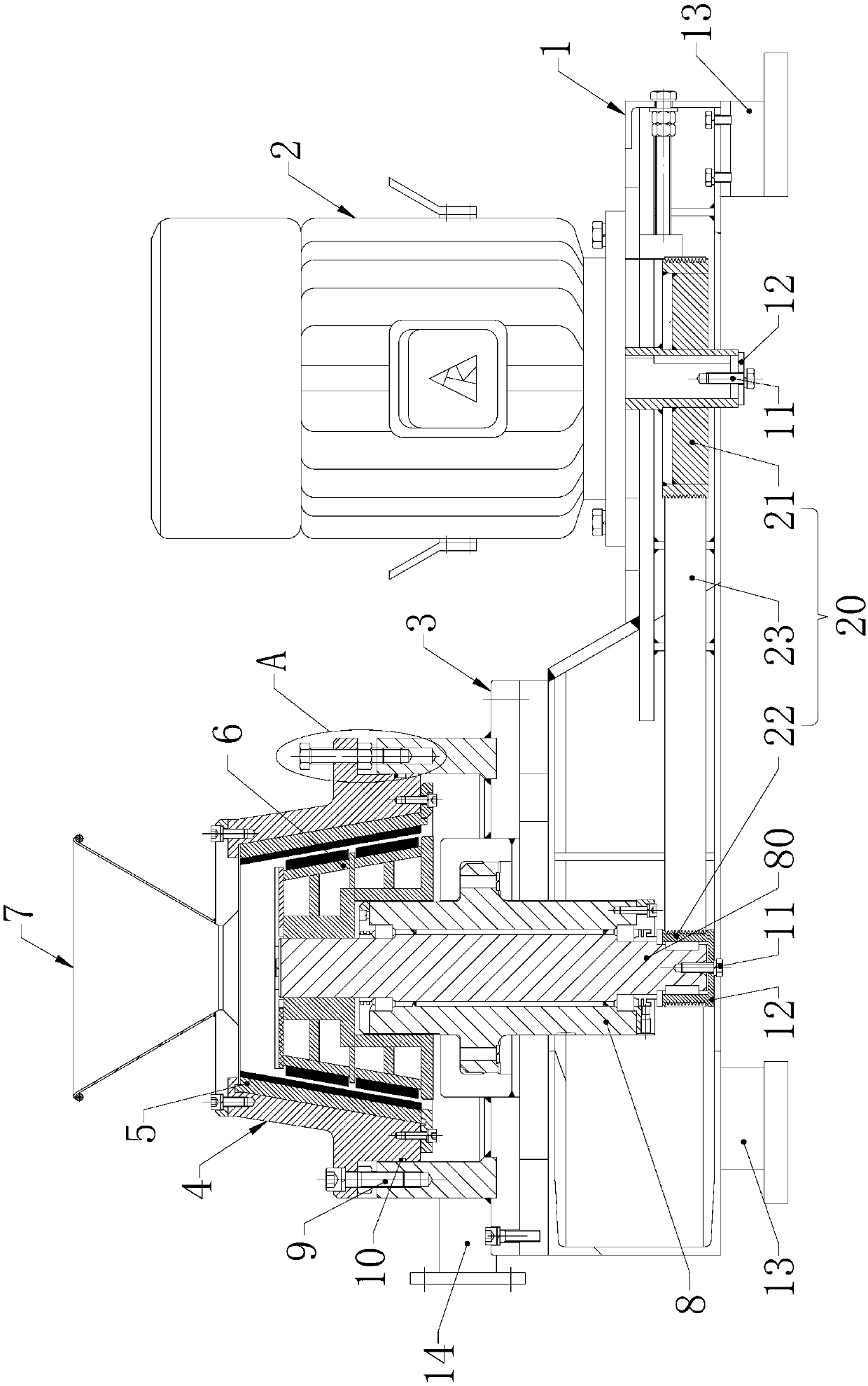

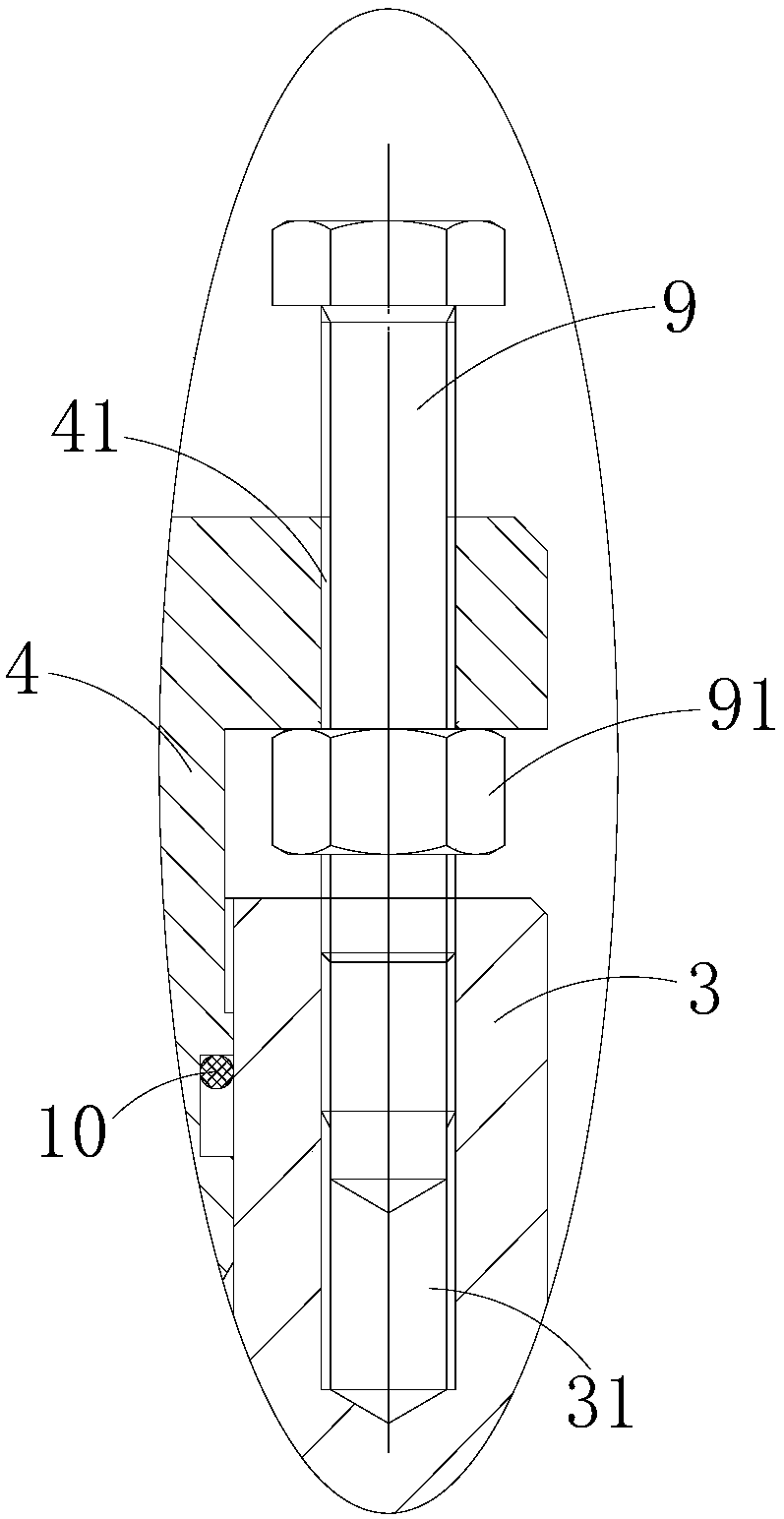

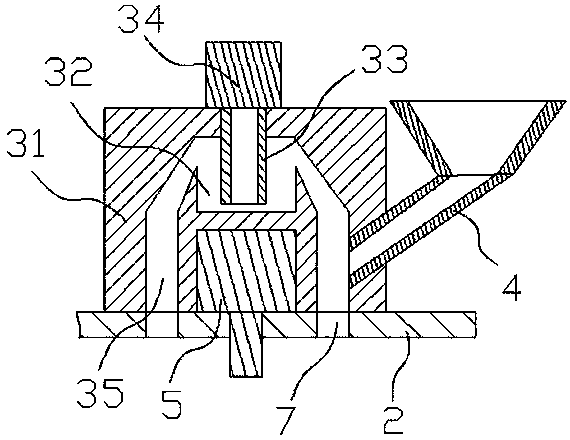

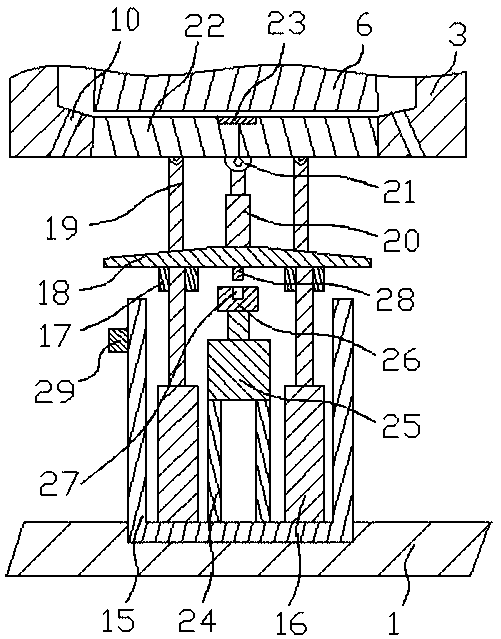

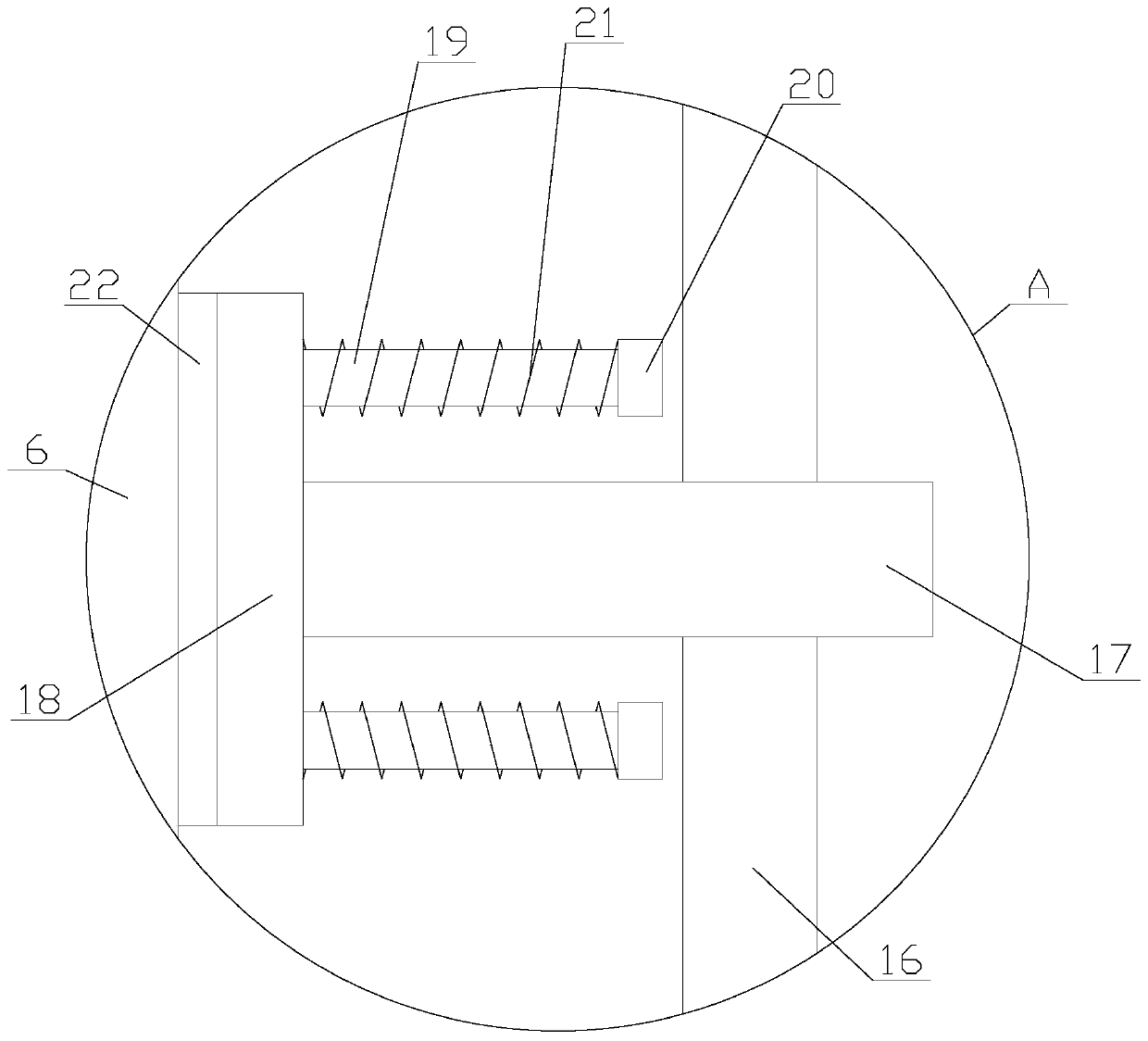

Automatic discharge device for back spindle

InactiveCN108788838ARealize automatic nestingSimple and fast operationPositioning apparatusMetal working apparatusProcess efficiencyEngineering

The invention discloses an automatic discharge device for a back spindle. The automatic discharge device comprises an elastic chuck, an ejector pin, a chuck sleeve and a bar charge hole, wherein the ejector pin is positioned in the elastic chuck; the elastic chuck is positioned in the chuck sleeve; the ejector pin is in threaded connection with a pushing rod I; the chuck sleeve is in threaded connection with a limiting sleeve; a return spring is arranged between the elastic chuck and the limiting sleeve; one end, close to the bar charge hole, of the chuck sleeve is in contact with a pushing rod II; the other end of the pushing rod II is in contact with a short arm of an opening-closing claw; a long arm of the opening-closing claw is in contact with a pneumatic performer; an ejecting springis arranged between the elastic chuck and the bar charge hole; and one side of the bar charge hole is equipped with an inducting switch. The automatic discharge device realizes an automatic chargingfunction and an automatic discharge function of the back spindle, is simpler and more convenient to operate, and is higher in processing efficiency.

Owner:HUBEI YIXING INTELLIGENT EQUIP CO LTD

Back spindle automatic discharging device

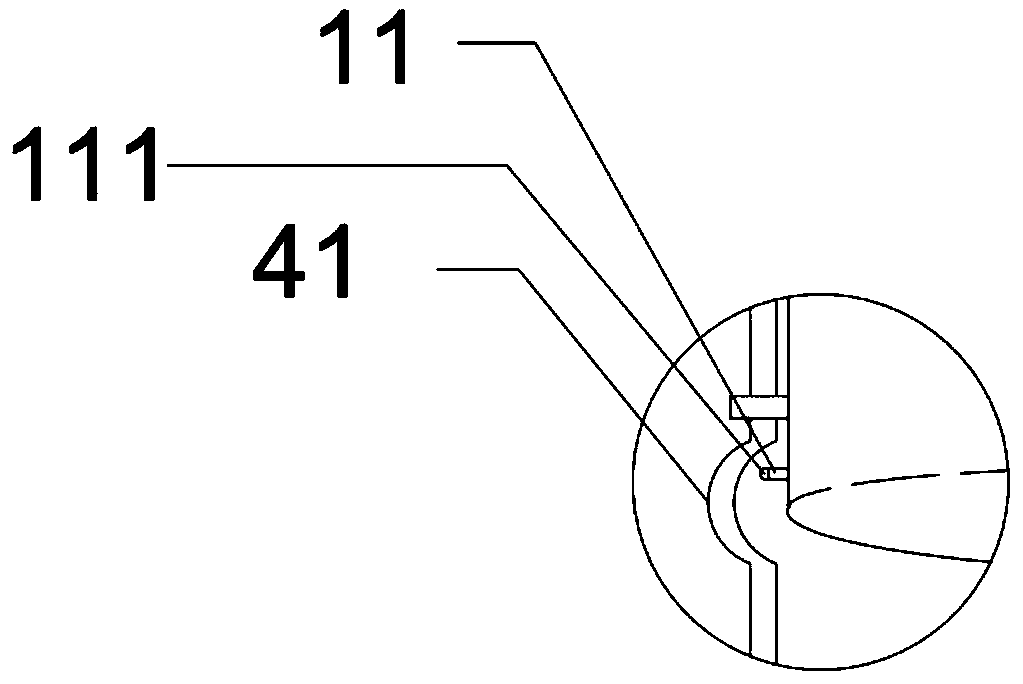

InactiveCN103028988ARealize automatic nestingSimple and fast operationPositioning apparatusMetal working apparatusEngineeringShort arms

The invention relates to a back spindle automatic discharging device which comprises an elastic chuck, an ejector pin, a chuck sleeve and a bar feed inlet. The ejector pin is positioned in the elastic chuck; the elastic chuck is positioned in the chuck sleeve; the ejector pin is in threaded connection with a first push rod; the chuck sleeve is in threaded connection with a limiting sleeve; a return spring is arranged between the elastic chuck and the limiting sleeve; one end of the chuck sleeve, which is close to the bar feed inlet, is in contact with a second push rod; the other end of the second push rod is in contact with a short arm of an opening and closing jaw; a long arm of the opening and closing jaw is in contact with a pneumatic actuator; an ejector spring is arranged between the elastic chuck and the bar feed inlet; and one side of the bar feed inlet is provided with an inductive switch. According to the invention, functions of automatically clamping and discharging a back spindle are implemented; and the back spindle automatic discharging device is simpler and more convenient to operate and has higher processing efficiency.

Owner:陈胜喜

Casting bait for fishing crucian

InactiveCN102217723AIncreased hungerStrongly stimulate the sense of tasteClimate change adaptationAnimal feeding stuffZoologyVegetable Proteins

The invention discloses casting bait for fishing crucian. The casting bait is composed of duck blood powder, pig blood powder, fresh scallop meal, silkworm chrysalis meal, tenebrio molitor meal, fish viscera meal, chicken meal, malt powder, 8 to 10% bean cake meal, fish attractant powder, fish feeding promoting agent powder, defatted milk powder, vegetable protein powder, water spice powder and sweet corn protein powder. The casting bait is prepared by the steps of: mixing all the powder together in a ratio and placing in a stirrer for stirring for 100 minutes; then taking out and placing in a drier for drying for 1 to 2 hours, wherein the temperature of the dryer is controlled to be 55 to 65 DEG C, and the dryness index of the dried substance is controlled to be 75 to 85%; taking out and cooling; then placing in the stirrer again for stirring for 120 minutes; taking out and placing in a bulking machine for bulking for 1 to 2 hours, wherein the temperature of the bulking machine is controlled to be 65 to 75 DEG C and the dryness index of the bulked substance is controlled to be 75 to 85%; and taking out, cooling, and then packaging.

Owner:王夫存

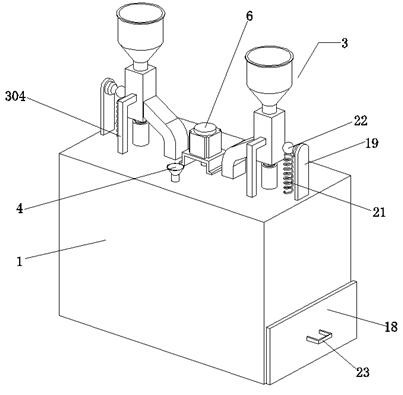

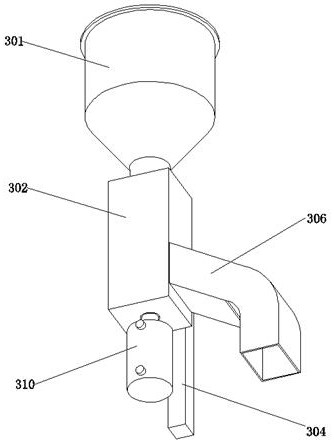

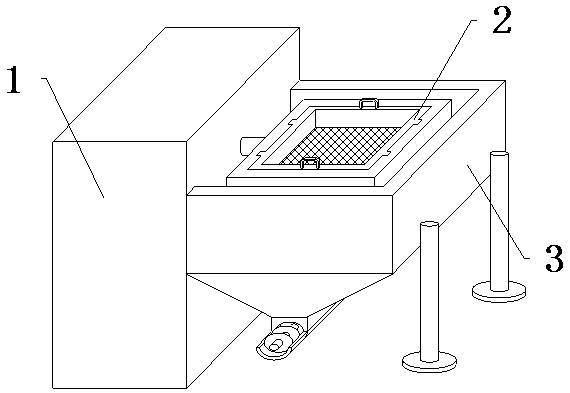

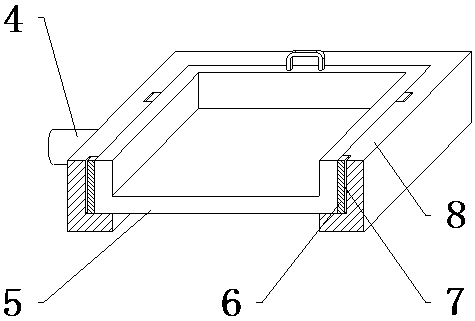

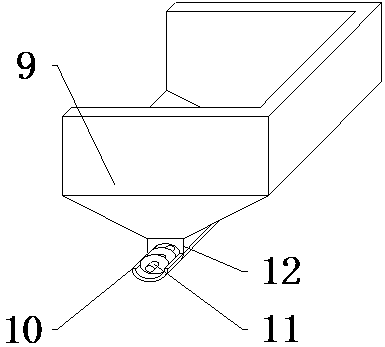

Epoxy polyester powder coating production equipment and production process thereof

ActiveCN113321008AAdjustable distanceImprove production nesting effectChemical industryPowdery paintsEpoxyPolyester

The invention discloses epoxy polyester powder coating production equipment and a production process thereof, and relates to the technical field of epoxy polyester powder coating production equipment. The epoxy polyester powder coating production equipment comprises a machine box and a box cover installed on the top of the machine box, the bottom of the machine box is fixedly connected with a discharging pipe, a valve is arranged on the discharging pipe, discharging parts are installed in the machine box, and the discharging parts are connected with the box cover. The epoxy polyester powder coating production equipment is reasonable in structure, by arranging a discharging gap adjusting unit, the distance between the discharging parts is adjusted, the particle size of discharged epoxy polyester powder coating is conveniently adjusted, the production requirements of epoxy polyester powder coating with different requirements are met, and the production cost caused by machining of different equipment is reduced; and by arranging a power transmission unit, reverse simultaneous rotation of the discharging parts is achieved, the discharging effect of production of the epoxy polyester powder coating is improved, the discharging speed of production of the epoxy polyester powder coating is increased, and the practicability is good.

Owner:肇庆市大雄岭新材料有限公司

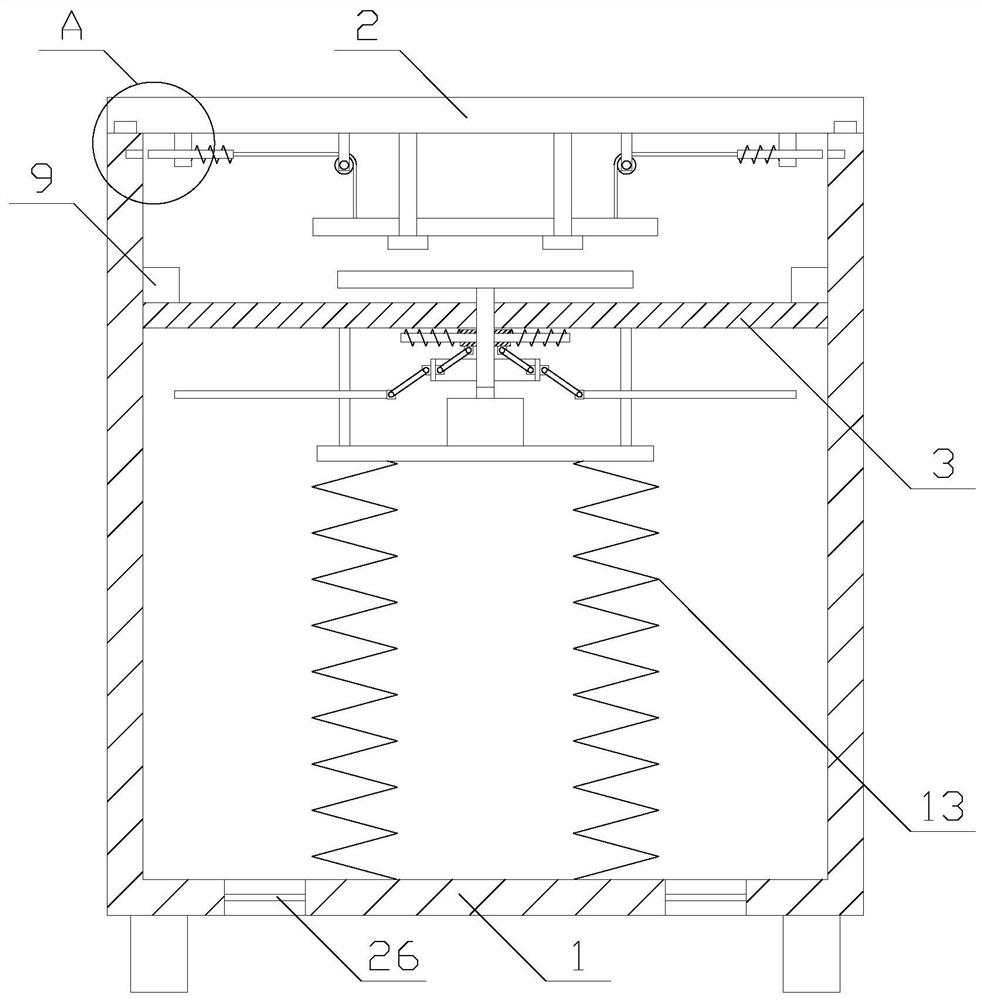

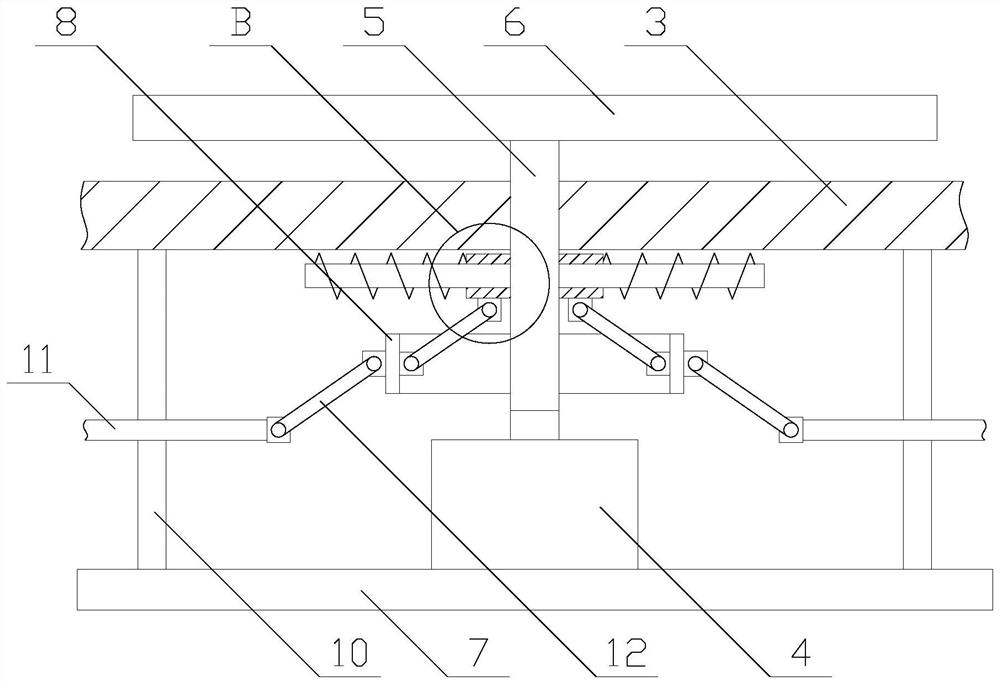

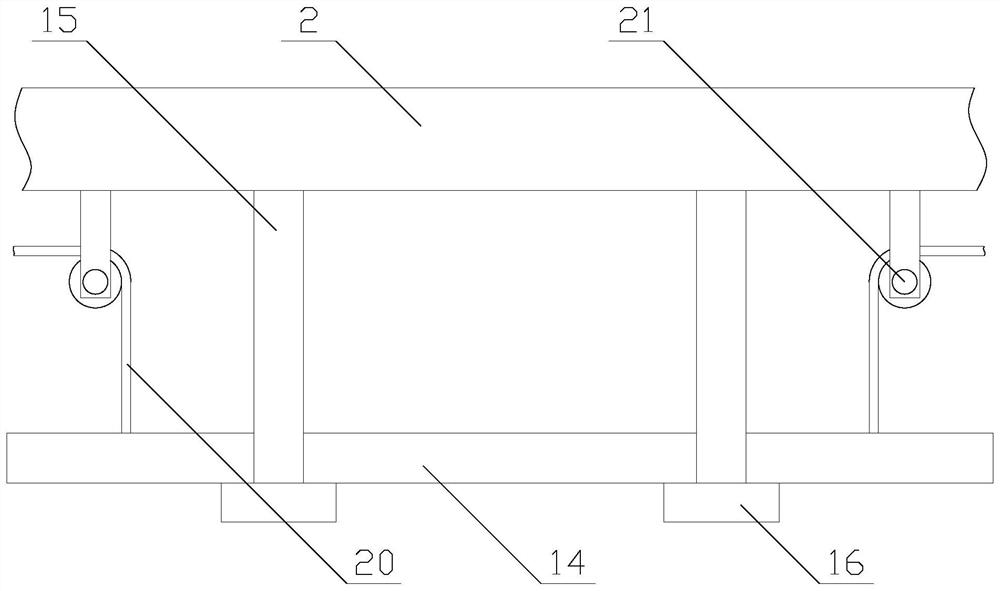

Efficient building engineering device

InactiveCN111633824AImprove stirring efficiencyImprove mixing uniformityDischarging apparatusCement mixing apparatusDrive shaftArchitectural engineering

The invention relates to an efficient building engineering device which comprises a body, a discharging pipe, a sealing cover, a driving motor, a transmission shaft, a bearing and a stirring rod. Thesealing cover is arranged on the top of the body in a covering manner and is connected with the body in a sealed manner. The discharging pipe is arranged at the bottom of the body. A sealing device isarranged on the discharging pipe. The transmission shaft is vertically arranged. A connecting hole is formed in the sealing cover. The transmission shaft penetrates the connecting hole. The transmission shaft slides on the inner wall of the connecting hole and is connected with the inner wall of the connecting hole in a sealed manner. The driving motor is in transmission connection with the top end of the transmission shaft and is fixedly connected with the sealing cover. The axis of the stirring rod and the axis of the transmission shaft are perpendicular to each other and are crossed. The stirring rod is located in the body, the middle end of the stirring rod is fixed to the bottom end of the transmission shaft, and an auxiliary mechanism and a discharging mechanism are arranged in thebody. By means of the efficient building engineering device, the stirring efficiency is improved through the auxiliary mechanism, and furthermore, the discharging efficiency is improved through the discharging mechanism.

Owner:南京虞如梦信息技术有限公司

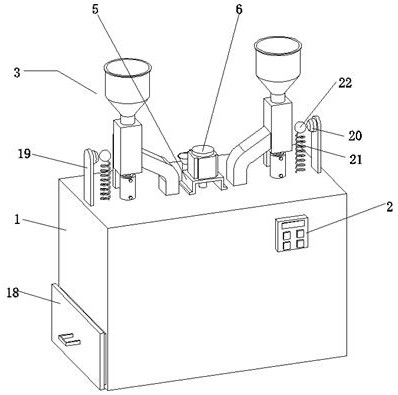

Accurate blending device for food additive

InactiveCN112439347ARealize accurate weighingContinuous operationRotary stirring mixersTransportation and packagingFood additiveElectric machinery

The invention relates to the technical field of food additive production equipment, and particularly discloses an accurate blending device for a food additive. The device comprises a box body, whereina plurality of quantitative feeding mechanisms and a liquid inlet hopper are arranged on the upper surface of the box body; a motor support is arranged at the center of the upper surface of the box body; a stirring motor is fixedly installed on the motor support; a rotating rod is connected to the lower end of a rotating shaft of the stirring motor and provided with a plurality of stirring blades; the lower end of the rotating rod is connected with a scraping plate; a stirring tank is arranged in the box body; the lower end of the stirring tank is connected with a collecting hopper; the lowerend of the collecting hopper is connected with a vertical through pipe; the left lower end of the vertical through pipe is connected with a discharging pipe; the bottom wall of the box body is fixedly connected with a vertical rod; the upper end of the vertical rod is connected with a fixing plug; and a plurality of first telescopic devices are fixed to the box body and fixedly connected with thecollecting hopper. The device disclosed by the invention can accurately weigh raw materials in proportion, and the prepared food additive is better in quality; and meanwhile, continuous operation isrealized, and processing efficiency is high.

Owner:含山县贝亲生物科技有限公司

Metal silicon production equipment with cleaning function

InactiveCN112661160AAvoid cloggingAffect the air purification effectSiliconDispersed particle filtrationProcess engineeringMechanical engineering

The invention relates to metal silicon production equipment with a cleaning function, which comprises a main body, an ash bucket, an air inlet pipe, a discharge pipe, a filter bag and a support disc; the ash bucket is arranged at the bottom of the main body, the discharge pipe is vertically arranged at the bottom of the ash bucket, the air inlet pipe is arranged on the main body, and an air outlet is formed in the top of the main body; the filter bag is cylindrical; the filter bag, the supporting disc and the air outlet hole are all coaxial with the discharging pipe, the hole diameter of the air outlet hole is smaller than the inner diameter of the filter bag, the filter bag and the supporting disc are both arranged in the body, the top end of the filter bag and the top in the body are sealed and fixedly connected, a cleaning mechanism is arranged on the filter bag, and an auxiliary mechanism is arranged on the ash bucket. According to the metal silicon production equipment with the cleaning function, the discharging effect is improved through the auxiliary mechanism, the discharging pipe is prevented from being blocked, and in addition, the function of cleaning the filter bag is achieved through the cleaning mechanism.

Owner:南京荷电新能源科技有限公司

Tilapia fishing nesting bait

InactiveCN101584410AIncreased hungerImprove nesting effectAnimal feeding stuffOther angling devicesTilapiaAnimal science

The invention discloses tilapia fishing nesting bait, which comprises the following powders by weight percent: 8 to 18 percent of pig lung powder, 7 to 19 percent of chicken intestine powder, 8 to 16 percent of pig blood powder, 5 to 11 percent of rough fish powder, 6 to 10 percent of lobster powder, 1 to 3 percent of decayed animal powder, 1 to 3 percent of decayed plant powder, 2 to 4 percent of expandable microspheres, 2 to 4 percent of fish hunger promoter powder, 2 to 4 percent of fish contrastimulant, 3 to 8 percent of strong adhesive and 20 to 35 percent of sweet corn protein powder. The tilapia fishing nesting bait is prepared by the following steps that: all of the powders are mixed together in proportion and put in a stirrer to be stirred for 100 minutes; after being taken out, the stirred mixture is put in a drier to be dried under the conditions that the temperature of the dryer is controlled to be between 45 and 55 DEG, that the drying time is 1 to 2 hours, and that the dryness of the dried substance is controlled to be 85 to 95 percent; the dried mixture is taken out, cooled and put into the stirrer to be stirred again for 80 minutes; the re-stirred mixture is taken out and put in an expanding machine to be expanded under the conditions that the temperature of the expanding machine is controlled to be between 65 to 85 DEG C, that the expanding time is 1 to 2 hours, and that the dryness of the expanded mixture is controlled to be 85 to 95 percent; and the expanded mixture is taken out, cooled and packaged.

Owner:昝金昨

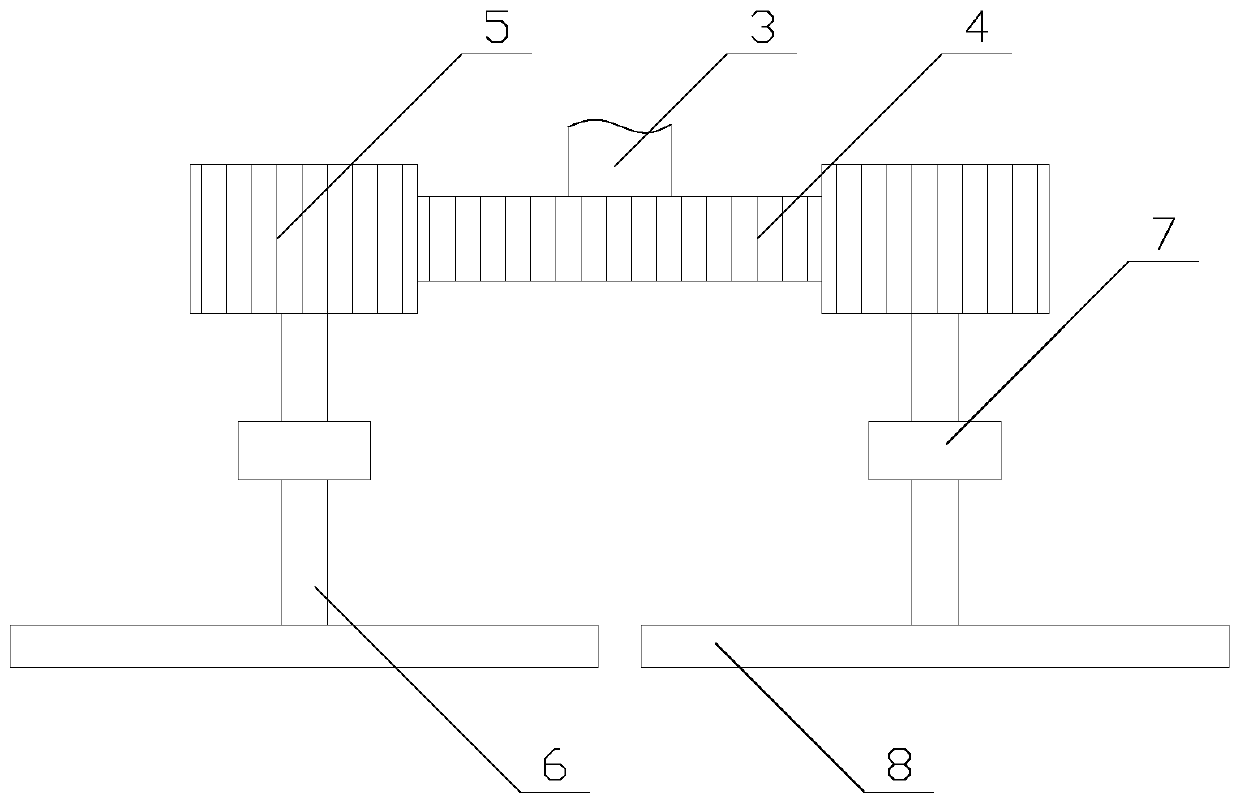

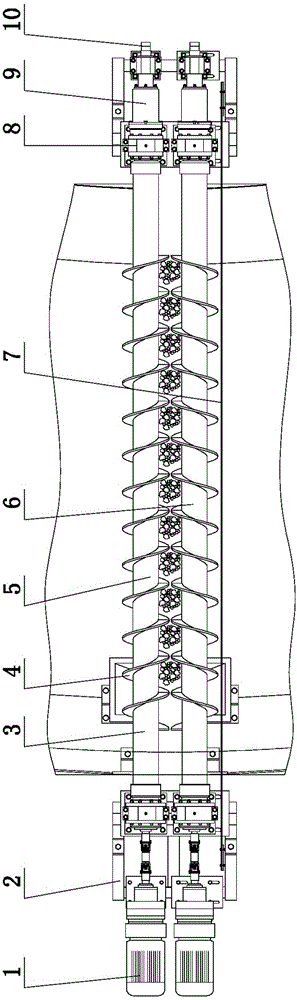

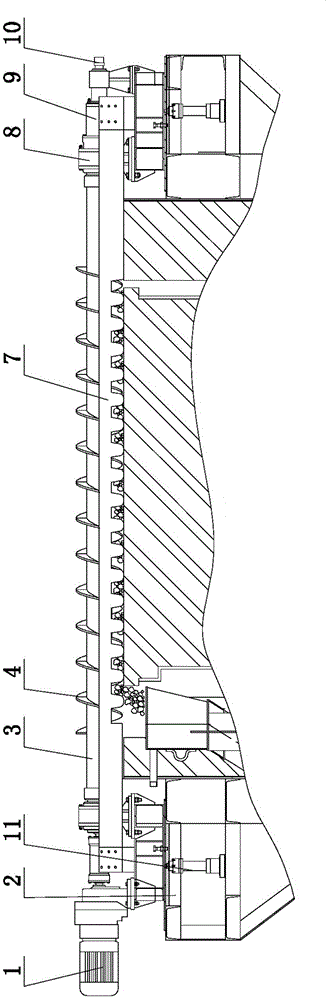

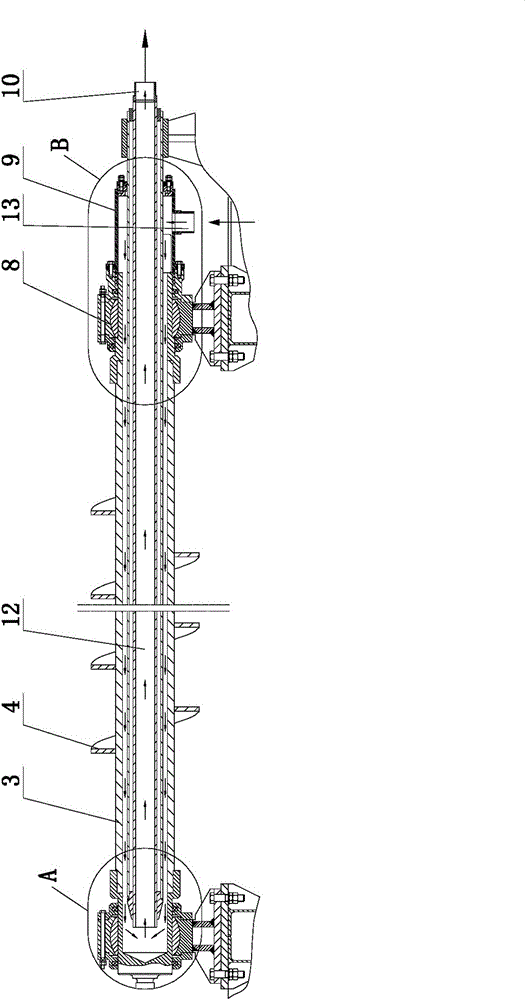

Discharge device for rotary hearth furnace

InactiveCN104006653AReduce scatterImprove nesting effectCharge manipulationFurnace typesEngineeringHearth

The invention discloses a discharge device for a rotary hearth furnace and relates to an improved structure of a water-cooling spiral discharge device for the rotary hearth furnace. The discharge device for the rotary hearth furnace comprises a first water-cooling spiral part, and is characterized in that a second water-cooling spiral part is opposite to the first water-cooling spiral part. The discharge device for the rotary hearth furnace has the advantages that the structure is simple, production and machining are easy and convenient, and the service life is long.

Owner:NFC (SHENYANG) METALLURGICAL MACHINERY CO LTD

Double-layer glass cup nest production process

InactiveCN109721225AIncrease productivityReduce manufacturing costGlass reforming apparatusDrinking vesselsComposite materialGas bubble

The invention discloses a double-layer glass cup nest production process, which comprises: (1) drawing; (2) blowing a billet; (3) nesting; (4) sticking a handle; and (5) sealing the bottom. Accordingto the present invention, the glass cup billet is blown by using a double-head burning lamp, such that the glass cup billet can be simultaneously burned through two fire outlets, and the gas bubbles in the burned glass cup are less so as to achieve the firm glass cup; by setting the nesting process, the nesting of the blown one-layer glass cup billet is replaced with the blowing into the two-layerbubble material in the original blowing process, such that the production efficiency is high, the production cost is low, and only 5 people are required for the original process requiring 10 people;the original production process can produce 500 double-layer glass cups while 700 double-layer glass cups can be produced by using the process including nesting so as to substantially save the labor costs and increase the yield; and the glass cup is subjected to nesting by using the pressing mold made of a lime material, such that the nesting effect is good, and the service life of the pressing mold is long.

Owner:王振

Novel stirring machine convenient to use and high in stirring efficiency

InactiveCN107053461AImprove stirring efficiencyAchieve regulationCement mixing apparatusHelical bladePulp and paper industry

The invention provides a novel stirring machine which is convenient to use and high in stirring efficiency. The novel stirring machine comprises a base frame and a stirring mechanism; a stirring cavity is formed in the base frame, a first rotation shaft is installed in the stirring cavity, and helical blades are installed on the first rotation shaft; a discharging frame is installed on the base frame and located at the second end of the first rotation shaft, a discharging through hole is formed in the discharging frame, and the upper end of the discharging through hole communicates with the lower end of the stirring cavity; multiple material guiding frames are installed on the base frame and located on the side, close to the first end of the first rotation shaft, of the discharging frame, the material guiding frames are sequentially arranged in the axial direction of the first rotation shaft, a material guiding through hole is formed in each material guiding frame, and the lower ends of the material guiding through holes communicate with the upper portion of the stirring cavity; the first stirring mechanism comprises a first gear, an arc-shaped plate, an installing frame, a stirring barrel and a second gear. According to the novel stirring machine which is convenient to use and high in stirring efficiency, use is convenient, the material stirring efficiency is high, and the discharging effect of the stirring barrel is excellent.

Owner:WUHU XIAOSHENG ELECTROMECHANICAL TECH CO LTD

Special digging bait for fishing channel catfish

InactiveCN101584402AIncreased hungerSwim quicklyAnimal feeding stuffOther angling devicesShrimpFinless eel

The invention relates to a special digging bait for fishing channel catfish, which comprises the following components by weight percent: 4-11 of fish powder, 3-5 of finless eel powder, 6-13 of chicken intestine powder, 8-16 of langouste powder, 5-9 of goat blood powder, 6-11 of goat intestine powder, 2-4 of water sachet powder, 2-4 of fishy odour powder, 2-4 of shrimp odour powder, 3-8 of hunger promoting agent powder for fish, 2-6 of fish contrastimulant powder, 2-4 of expansion powder, 2-4 of bulking powder, 3-5 of strong bond powder, 5-9 of corn powder, 3-8 of milk essence powder and 8-13 of wheat protein powder. A method for preparing the special digging bait for fishing channel catfish comprises the following steps: combining the powders together according to the weight percent; placing the powders into a stirring mill to stir for 80 minutes; taking the powders out from the stirring mill and placing into a drier, and controlling the temperature of the drier to be 35-45 DEG C, the drying time to be 1-2 hours and the dryness of the dried substances to be 60-75 percent; taking the powders out from the drier, cooling and placing into the stirring mill again to stir for 60 minutes; taking the powders out from the stirring mill and placing into a bulking machine for bulking, and the controlling the temperature of the bulking machine to be 60-95 DEG C, the bulking time to be one hour and the dryness of the bulked substance to be 85-95 percent; and finally taking the bulked powder out from the bulking machine and packing.

Owner:刘世得

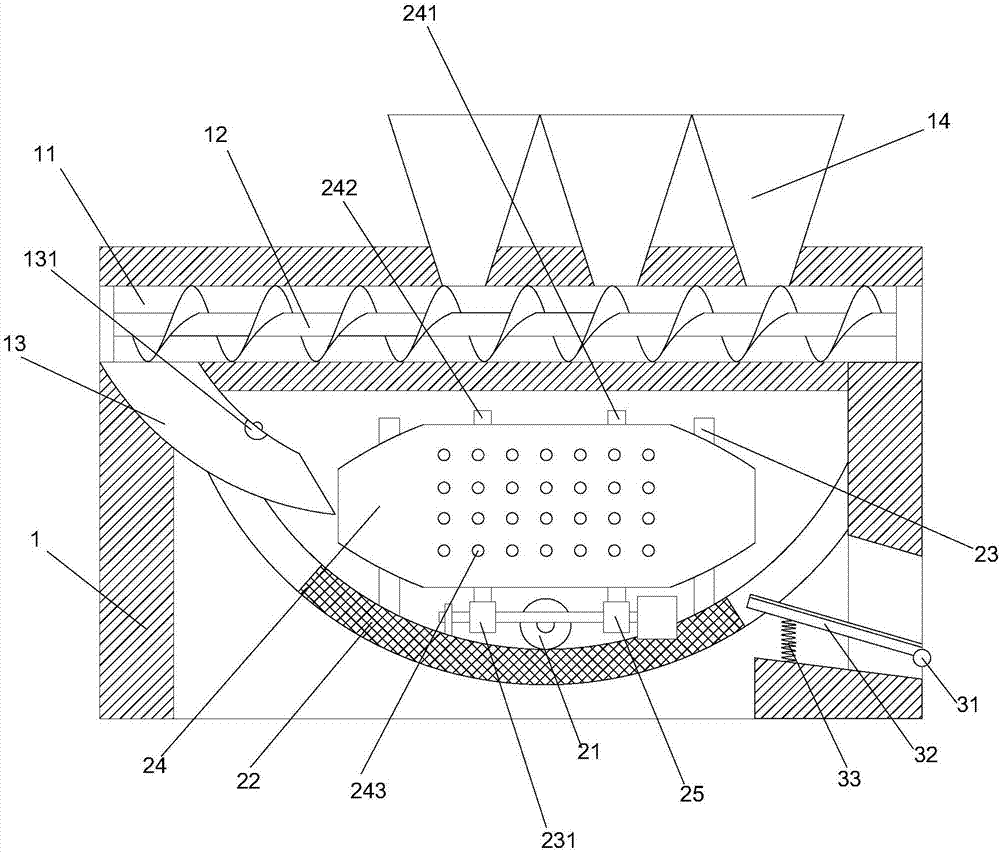

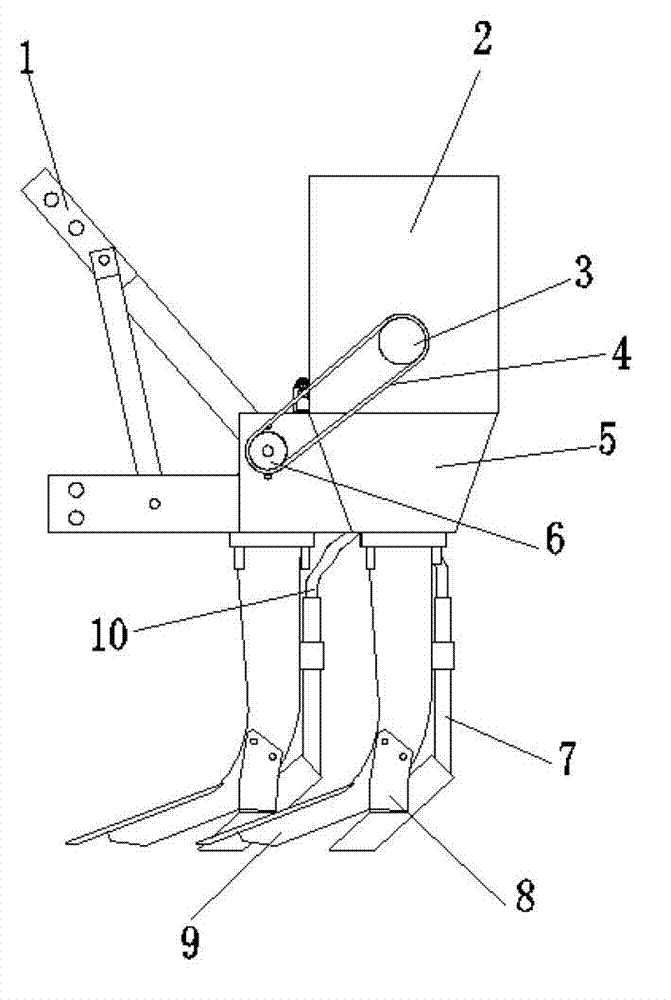

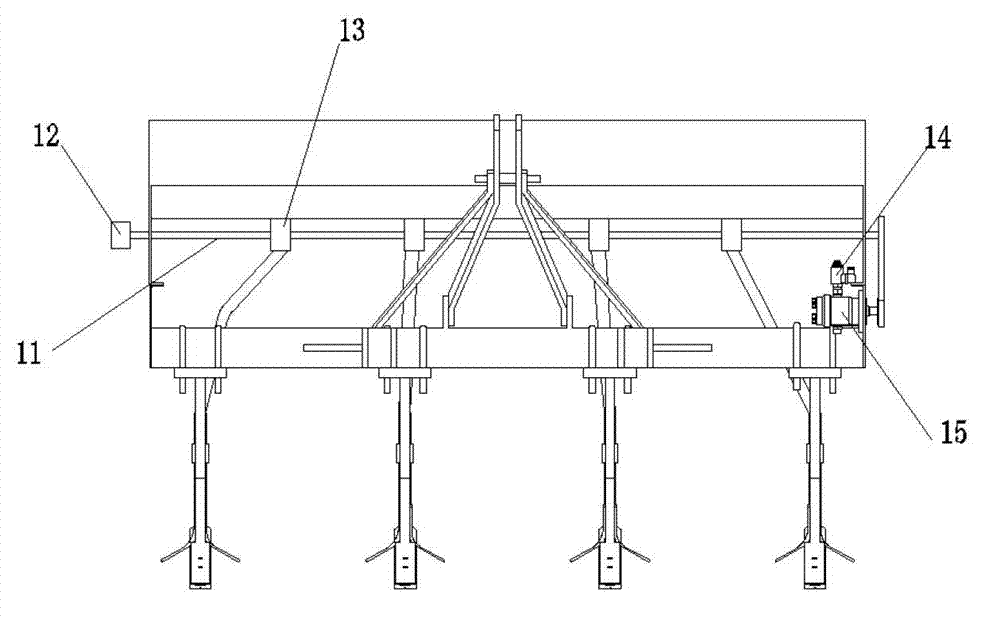

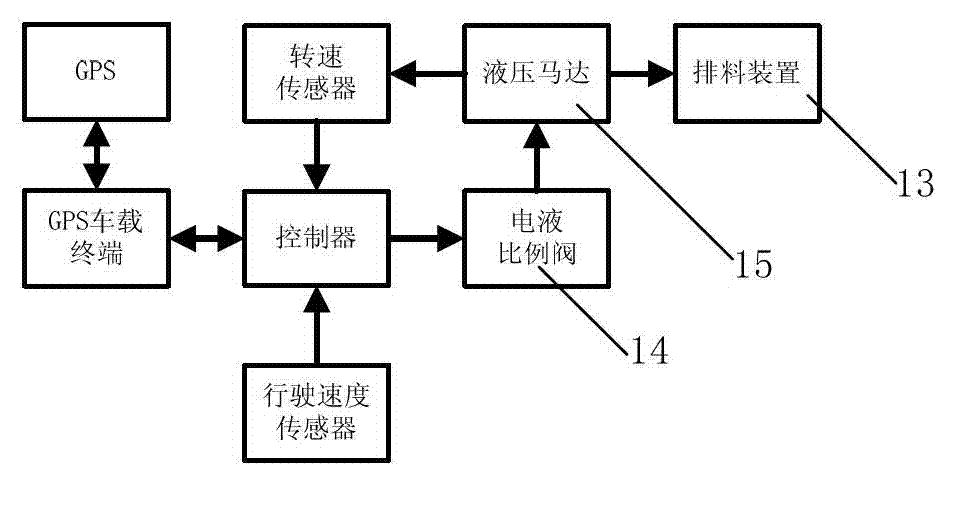

Damaged farmland improving device and material discharging control method thereof

ActiveCN103190215AEasy to useReal-time adjustment of discharge volumeSoil lifting machinesSoil-working equipmentsHydraulic motorAgricultural engineering

The invention relates to the field of agricultural machinery, in particular to a damaged farmland improving device and a material discharging control method thereof. The damaged farmland improving device comprises a machine frame, a material box arranged on the machine frame, a material discharging device, a material discharging pipe, a break shovel and a hydraulic motor. The material discharging device is driven to work through the hydraulic motor, a soil conditioner in the material box is discharged into ploughed soil, a mechanical degree is high, material discharging is even, labor intensity is reduced, and a use effect of the soil conditioner is improved. Simultaneously, the material discharging control method of the damaged farmland improving device uses a global positioning system (GPS) vertical-mounted terminal to control the material discharging device of the damaged farmland improving device intelligently through a controller and the hydraulic motor, soil conditioner discharging amount can be adjusted in real time, material discharging is intelligent, and a material discharging effect is good.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

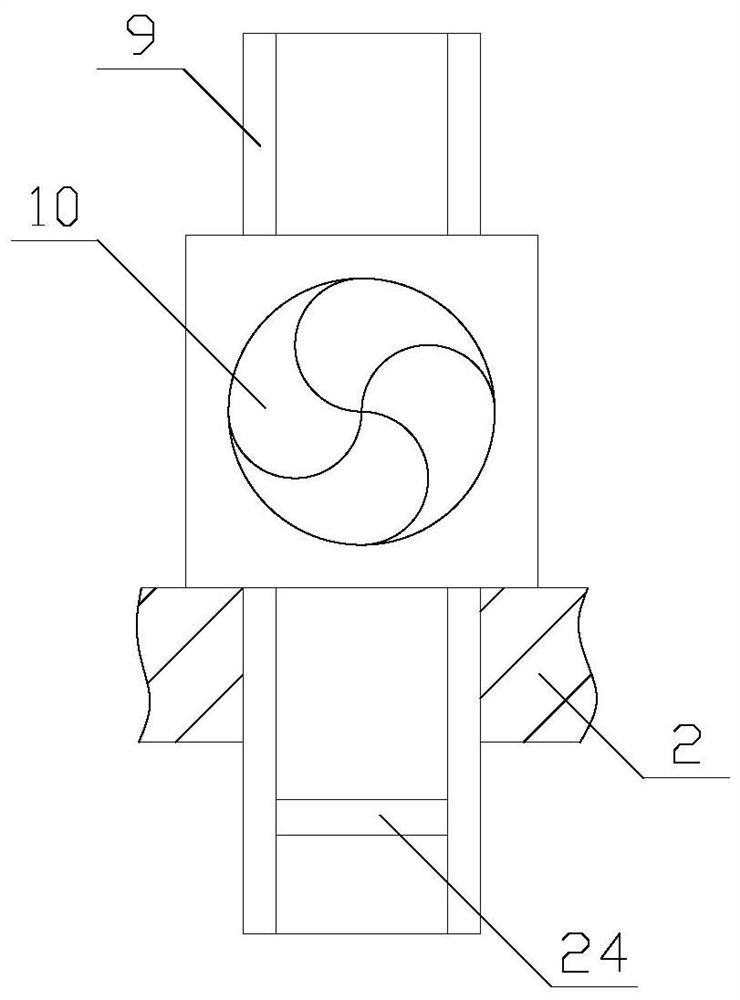

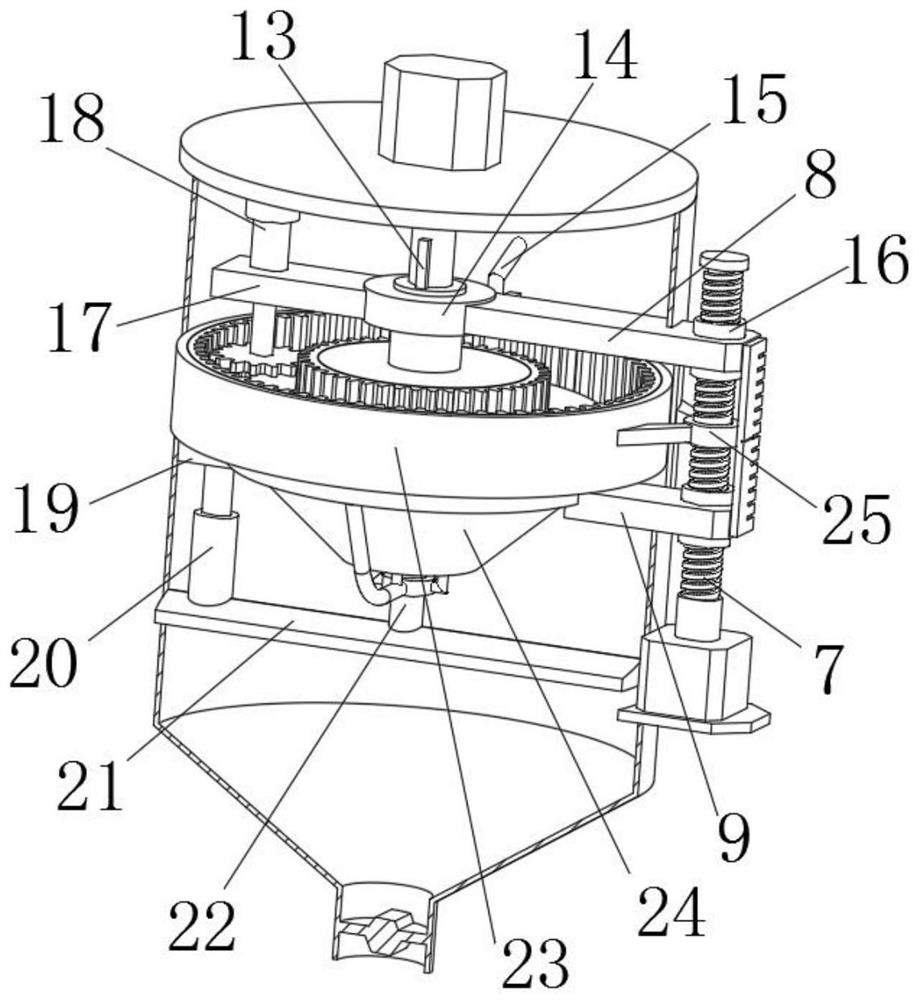

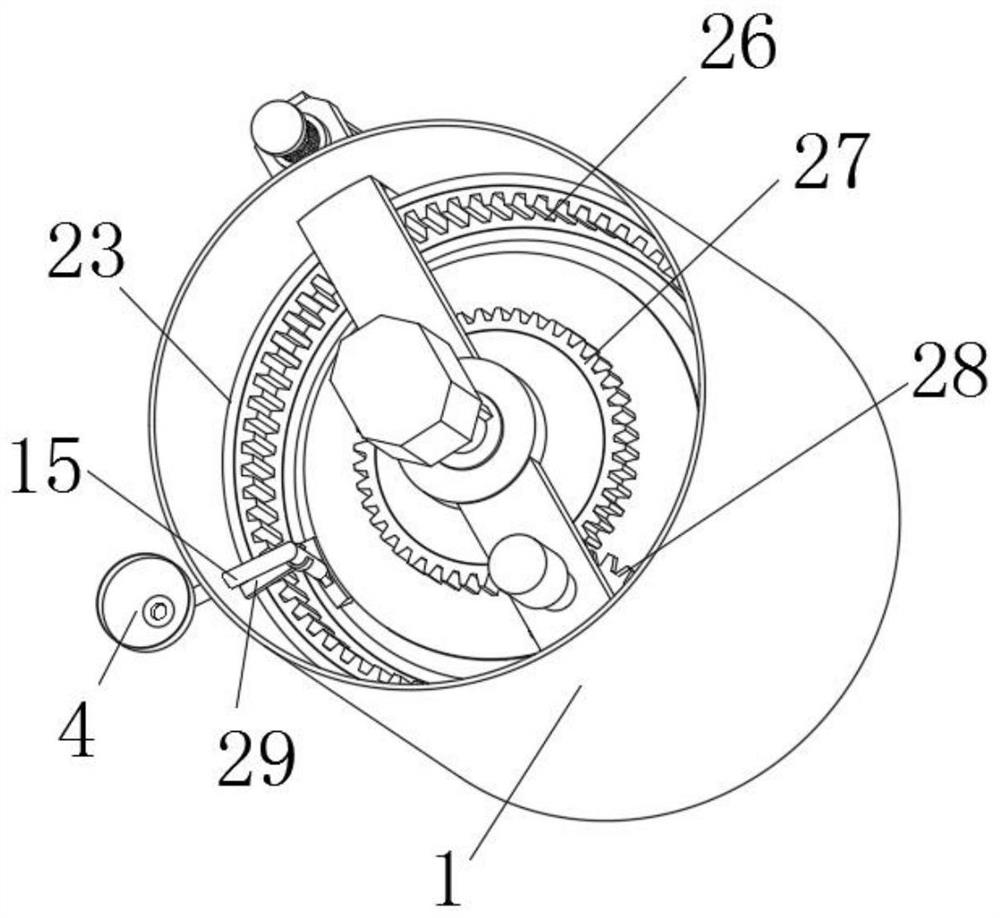

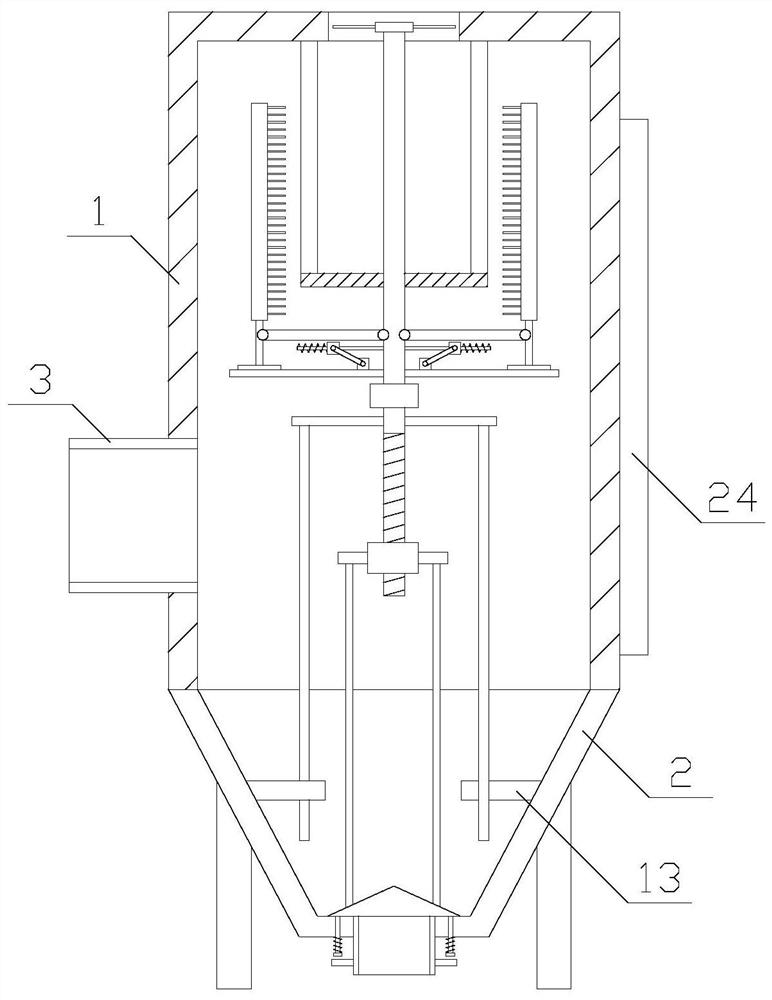

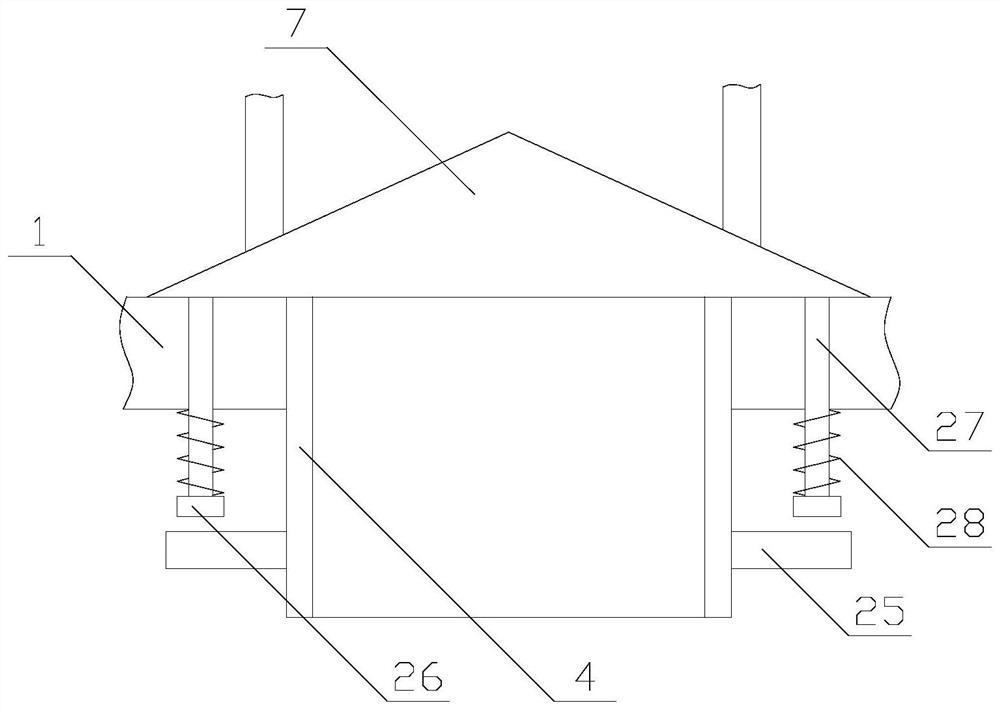

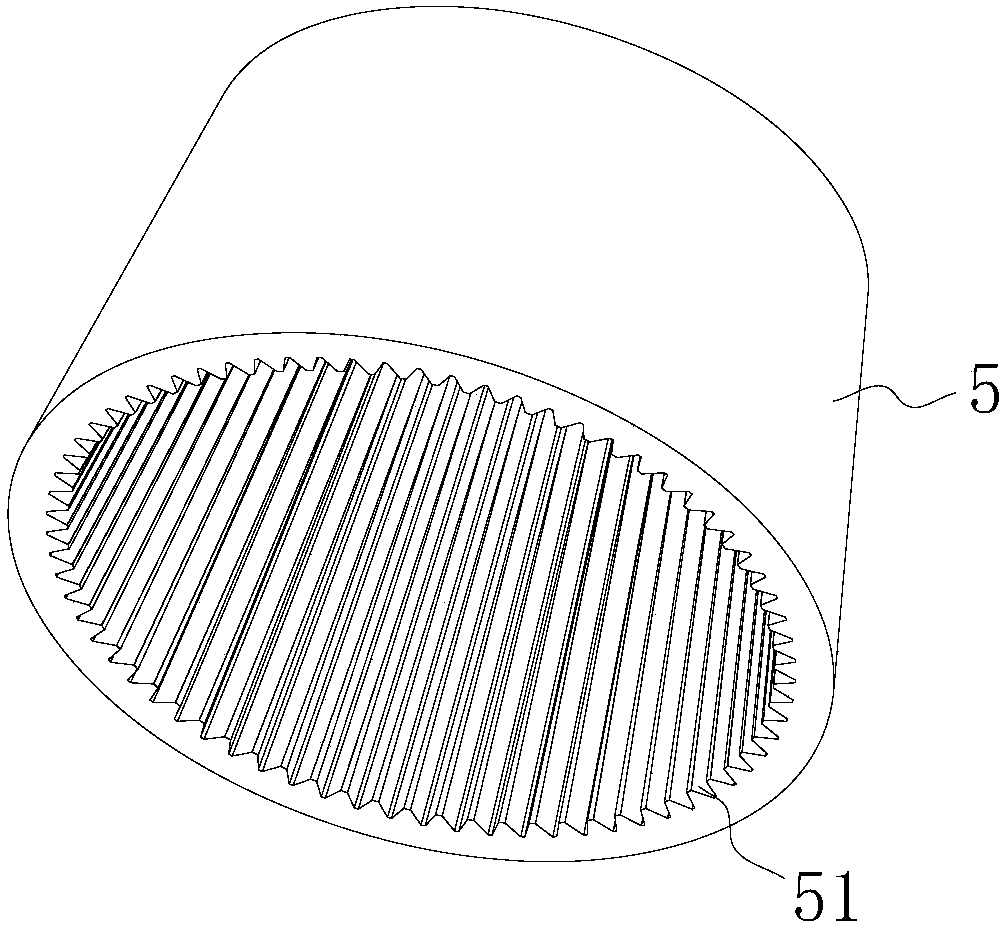

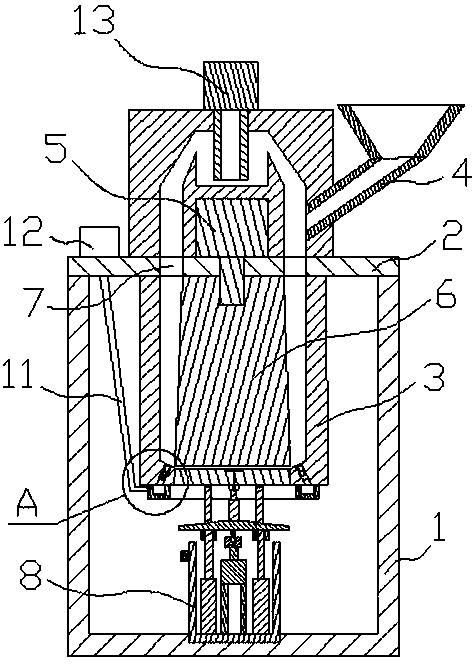

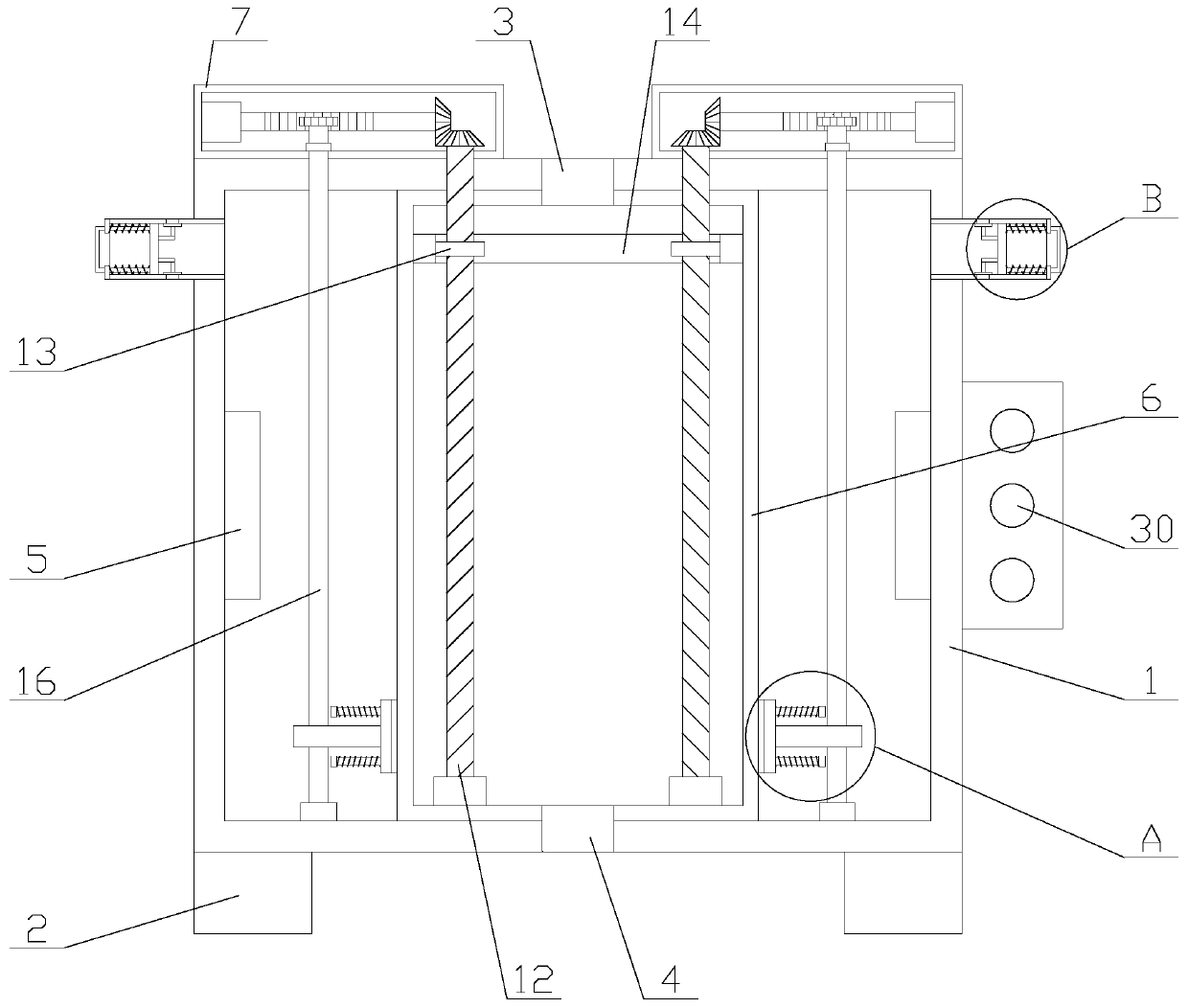

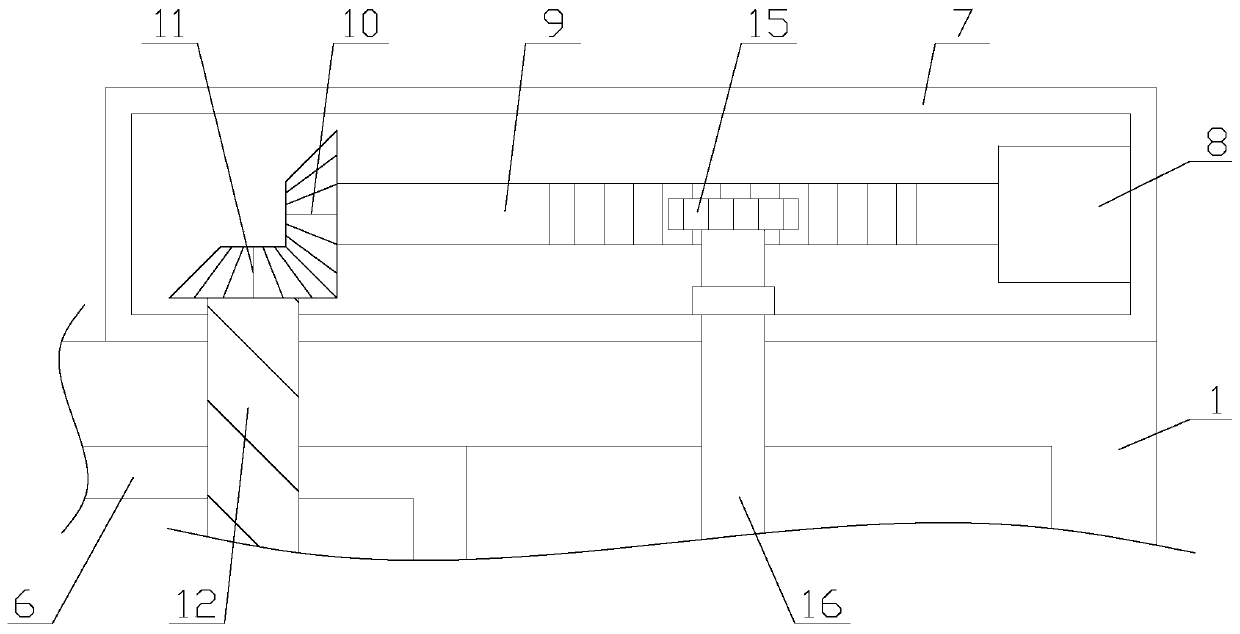

High-speed vortex pulverizing and airflow collection modification device

PendingCN107597292AReasonable structureImprove nesting effectGrain treatmentsElectric machineryAgricultural engineering

The invention discloses a high-speed vortex pulverizing and airflow collection modification device which comprises a rack, a motor, a lower box body, an upper box body, a stator, a rotor, a feed hopper and a bearing pedestal, and further comprises adjustment bolts; the upper box body is arranged on the lower box body and is connected with the lower box body through the adjustment bolts; the motorand the lower box body are fixedly arranged on the rack; the bearing pedestal is arranged on the lower box body; a rotary shaft is arranged in the bearing pedestal through a bearing; the upper end ofthe rotary shaft is connected with the rotor in a matching manner; the lower end of the rotary shaft is in transmission connection with an output shaft of the motor through a transmission mechanism; the stator is fixed in the upper box body; and the rotor is located in an inner cavity of the stator. Alloy blades are arranged in the rotor and alloy bars are arranged on the stator, so that the abrasion resistance of the alloy blades is improved; the angle between each alloy blade and the corresponding alloy bar is 30 degrees, so that the discharge ability of the high-speed vortex pulverizing andairflow collection modification device is improved effectively; the clearance between the stator and the rotor is adjusted through the adjustment bolts, so that the production requirements of products in different degrees of fineness are met, and the application scope of the high-speed vortex pulverizing and airflow collection modification device is extended.

Owner:余绍火

Powder liquid processing mechanism for nano metal powder processing

The invention relates to a powder liquid processing mechanism for nano metal powder processing. The powder liquid processing mechanism comprises a configuration cylinder; a cylinder cover is arrangedabove the configuration cylinder; a grinding cylinder is arranged under the middle of the cylinder cover; a conical column-shaped grinding block, which is smaller at the upper part and larger at the lower part, is arranged in the grinding cylinder in a matching way; the cylinder cover is provided with feeding holes matched with the grinding cylinder; the grinding block is matched with a grinding motor arranged above the cylinder cover; a discharge hole is formed at the lower part of the grinding cylinder and is matched with a discharge opening and closing device arranged in the configuration cylinder; a liquid feed device matched with the feeding holes is arranged at the upper part of the cylinder cover in a matching way and is nested at the outer side of the grinding motor; a liquid feedchannel of the liquid feed device is connected with a feeding pipe; the powder liquid processing mechanism can realize the integrated processing of grinding and concentration configuration of metal powder, and can enable a solution to wash the ground part of metal powder, thus realizing a good synergistic effect and greatly increasing the working efficiency.

Owner:DONGGUAN UNIV OF TECH

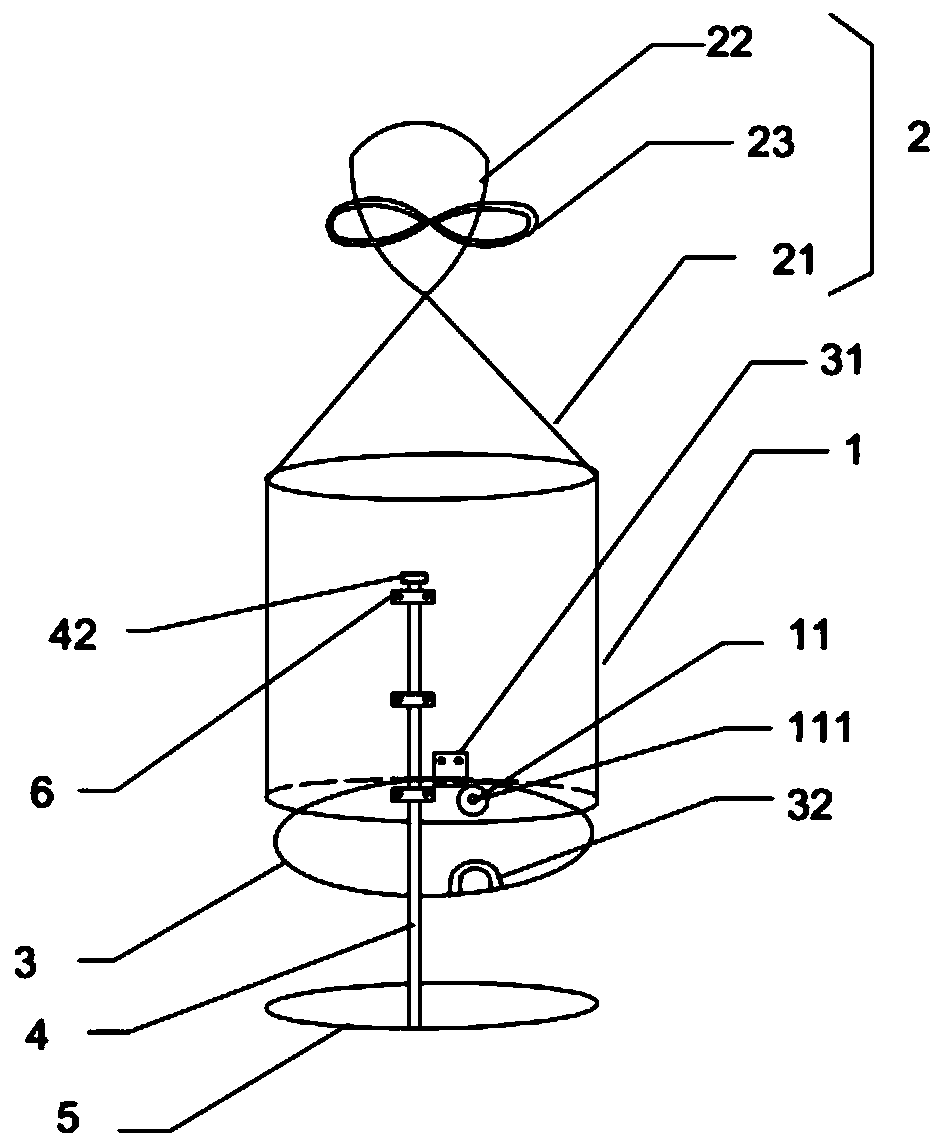

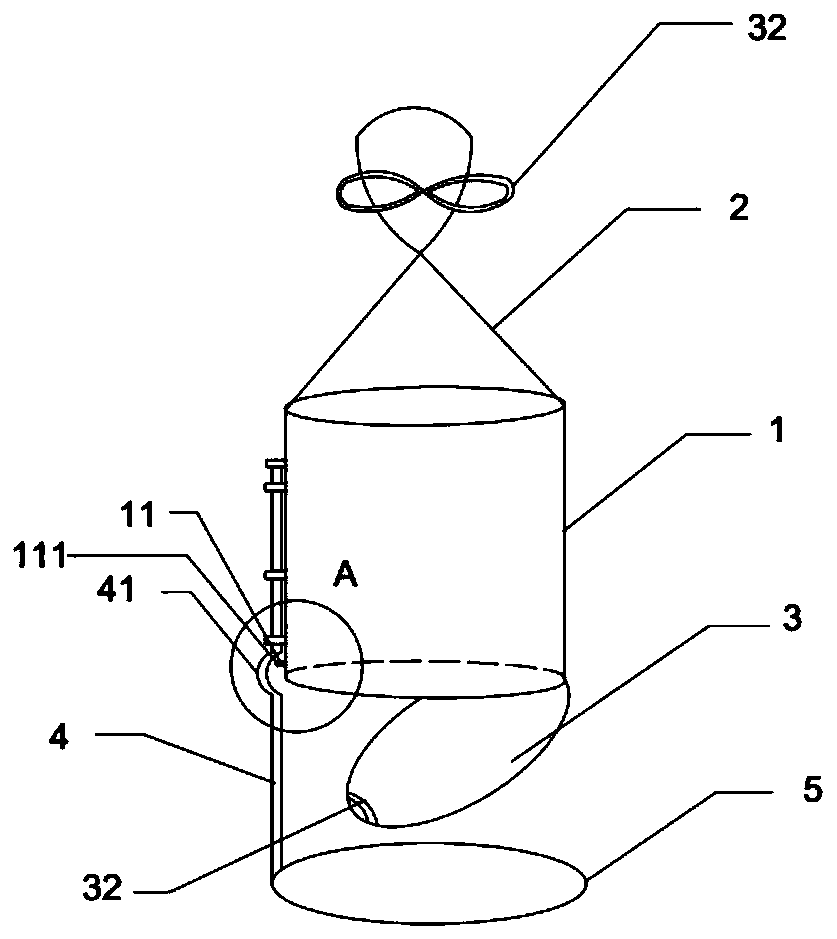

Portable fishing bait-throwing device

PendingCN111066752AEasy to carry for fishingAutomatically fall intoOther angling devicesEngineeringZoology

The present invention relates to a portable fishing bait-throwing device. The portable fishing bait-throwing device comprises a cylinder with openings at upper and lower ends, an upper end of the cylinder is provided with an adjustable connecting part, and the connecting part is connected with a fishing line; a lower end of the cylinder is hinged with a supporting plate and the supporting plate ismovably clamped at the opening at the lower end; a connecting rod is arranged on an outer side wall of the cylinder and moves up and down within a preset range; a lower end of the connecting rod is connected with a circular ring and a central line of the circular ring is collinear with a central axis of the cylinder; and a side wall of the cylinder is also provided with a plurality of through-holes. By arranging the connecting rod capable of up and down adjustment and by arranging the circular ring at a lower end of the connecting rod, a bait-throwing effect of the device before fishing can be improved, and by arranging the hinged supporting plate clamped on the cylinder via a clamping ring, the bait-throwing device can be convenient for realize bait installing and bait automatic fallinginto water during bait-throwing, realizes fixed-point throwing of bait, is strong in function and can be widely applied in the fishing device technical field.

Owner:陈沪海

Concrete stirring device for building construction

InactiveCN114833942AAvoid cleanup effectAffect the blending effectUsing liquid separation agentMixing operation control apparatusArchitectural engineeringBuilding construction

The invention discloses a concrete stirring device for building construction, and relates to the technical field of concrete stirring. The concrete stirring device for building construction comprises a device body, a driving device is fixedly installed at the bottom of the device body, a rotating shaft is fixedly installed at the output end of the driving device, a stirring rod is rotatably installed on the surface of the rotating shaft, and a scraping plate is hinged to the end, away from the rotating shaft, of the stirring rod. According to the concrete stirring device for building construction, a stirring plate and a scraping plate can be driven to rotate through a rotating shaft, a pushing rod can be driven to move through a sliding rod, the pushing rod can push a sliding block to move downwards, and the sliding block can push a stirring rod to rotate through transmission of a linkage rod; the stirring rod can drive the scraping plate to be attached to the interior of the device body, the stirring rod drives the scraping plate to rotate so that the scraping plate can clean the inner wall of the device body, and it is avoided that concrete remains on the device body.

Owner:徐吉良

Throwing special bait for fishing blunt-snout breams

InactiveCN101611792AIncreased hungerImprove nesting effectAnimal feeding stuffOther angling devicesBlunt snout breamDrying time

The invention relates to throwing special bait for fishing blunt-snout breams, which comprises the following components in percentage by weight: 12-30 percent of white fish powder, 10-20 percent of chick intestine powder, 2-6 percent of silkworm powder, 3-9 percent of lobster powder, 5-15 percent of bone powder, 2-6 percent of plant corrosive powder, 3-9 percent of expanded powder, 2-4 percent of hungry promoting agent powder for fish, 2-4 percent of contrastimulant for fish, 3-9 percent of milk powder, 15-25 percent of wheat protein powder and 1-3 percent of puffing powder. The throwing special bait is prepared by the following steps: combining all the powder together according to a certain proportion; placing the mixture into an agitator and stirring for 180 minutes; taking the mixture out and then placing the mixture into a drier; controlling the temperature of the drier between 80 DEG C and 85 DEG C, the drying time to be 1 hour-3 hours and the drying degree of the dried substances to be 85 percent-95 percent; after taking out and cooling the dried substances, placing the dried substances into the agitator and stirring for 180 minutes; taking the dried substances out and then placing the dried substances into a puffing machine for puffing; controlling the temperature of the puffing machine between 65 DEG C and 85 DEG C, the swelling time to be 1 hour-2 hours and the drying degree of the dried substances to be 85 percent-95 percent; and taking out, cooling and packing.

Owner:韩玉根

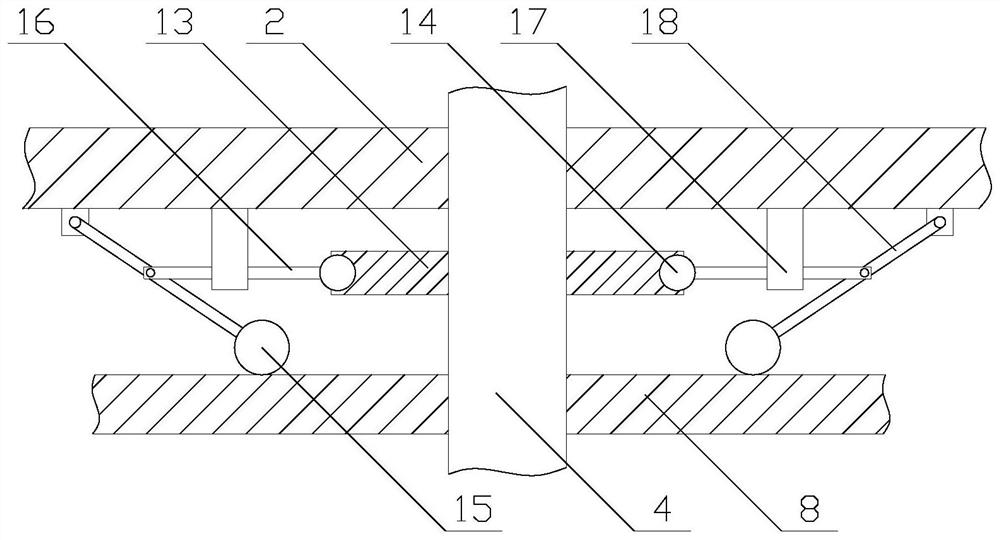

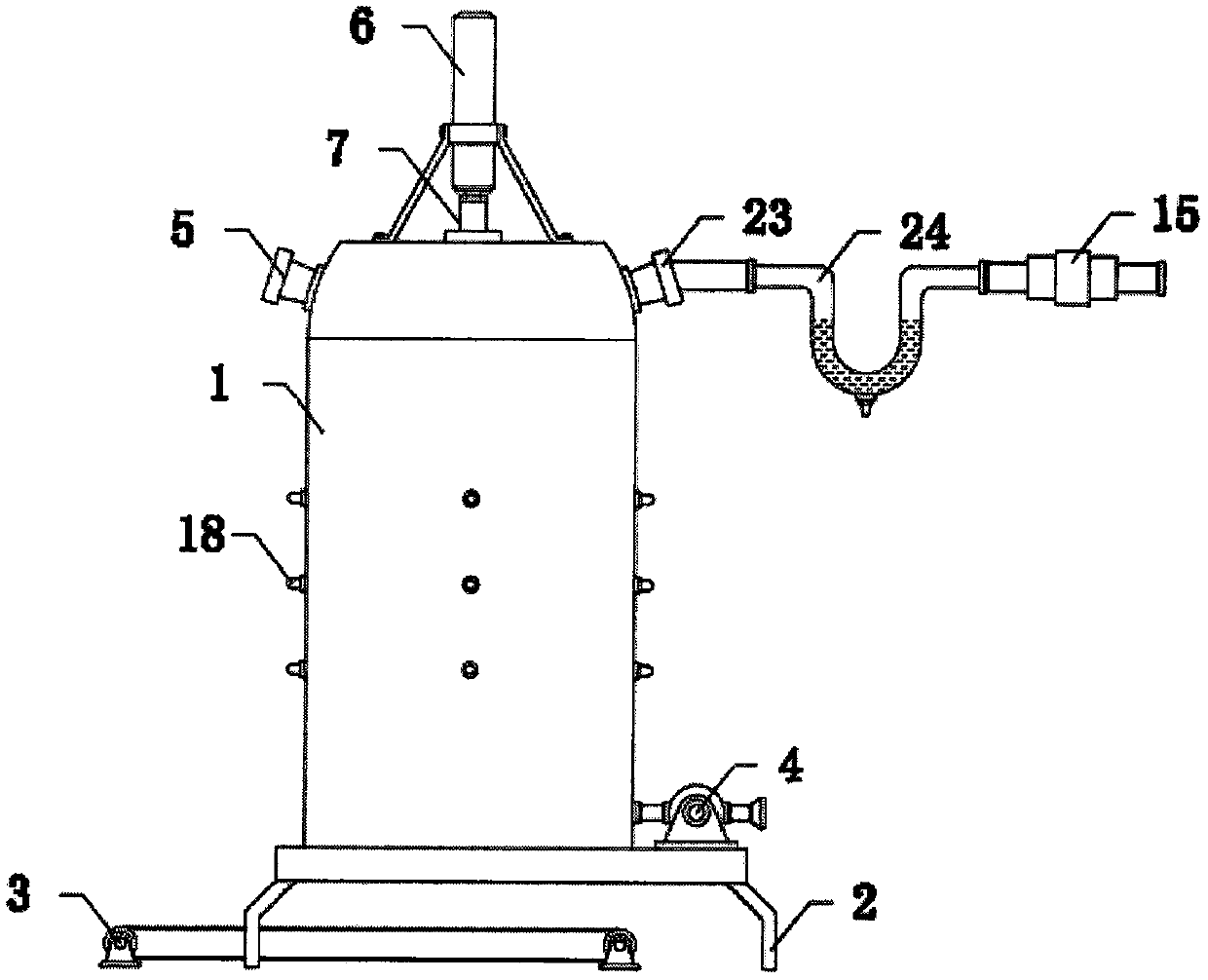

Beverage production equipment with high safety coefficient

InactiveCN112999940AImprove convenienceImprove nesting effectShaking/oscillating/vibrating mixersTransportation and packagingDrive shaftElectric machinery

The invention relates to beverage production equipment with a high safety coefficient, the beverage production equipment comprises a cylindrical stirring barrel and a sealing cover, the stirring barrel is vertically arranged, the sealing cover is hermetically arranged at the top end of the stirring barrel, a stirring mechanism and a connecting mechanism are arranged in the stirring barrel, and the stirring mechanism comprises a lifting disc, a driving motor, a transmission shaft, a stirring rod, a lifting plate, a bearing and two stirring assemblies, each stirring assembly comprises a limiting block, a fixed rod, a movable rod, a first connecting rod, a first spring, an air hole and a stirring unit, and the connecting mechanism comprises a power assembly and two connecting assemblies. According to the beverage production equipment with the high safety coefficient, the function of stirring raw materials is achieved through the stirring mechanism, and in addition, the safety is improved through the connecting mechanism.

Owner:深圳市群卜鸿科技有限公司

Casting bait for fishing silver carps

InactiveCN101946859AIncreased hungerGood nesting effectBaitAnimal feeding stuffAnimal proteinSorghum

A casting bait for fishing silver carps comprises sorghum powder, soybean cake powder, tenebrio molitor powder, earthworm powder, loach powder, plant protein powder, animal protein powder, fish food attractant powder, incense powder in water, used adhesive powder, chicken blood powder, duck blood powder, chicken intestine powder, fish atomized powder, drawing powder, fish hormone and stimulant powder and sweet potato protein powder. The casting bait is characterized by taking the powder according to the proportion and combining all the powder together, putting the powder into a stirrer to be stirred for 140 minutes, taking out and putting the mixture into a dryer to be dried at a controlled temperature of 65-75 DEG C for 1-2 hours, controlling the dryness of the dried matters to be 75-85%, taking out and cooling the matters and then putting the matters into the stirrer to be stirred for 150 minutes, taking out and putting the stirred matters into a swelling machine to be swelled at a controlled temperature of 75-85 DEG C for 1-2 hours, controlling the dryness of the swelled matters to be 80-90% and taking out and cooling the swelled matter to be packed.

Owner:路培进

Noise-reducing conducting device of waste pyrolysis gasification furnace

PendingCN110145743AEvenly heatedGood stage responseIncinerator apparatusHydraulic cylinderPulp and paper industry

The invention belongs to the technical field of waste pyrolysis, and specifically discloses a noise-reducing conducting device of a waste pyrolysis gasification furnace. The noise-reducing conductingdevice comprises a furnace body and a support base arranged on the bottom of the furnace body, wherein a charge hole and a gas outlet are formed in the upper end of the side wall of the furnace body;the bottom end of the side wall of the furnace body is equipped with an air inlet machine; an air outlet of the air inlet machine communicates with an inner cavity of the furnace body; the upper end of the furnace body is equipped with a rotary motor through a motor base; the rotary motor can be matched with a drive hydraulic cylinder for driving a supporting base and a storage cover to longitudinally move; moreover, a turnover bracket can be driven to rotate for turning over waste in the supporting base and the storage cover, so that waste is heated uniformly; and a drying region, a pyrolysisregion, an oxidizing region and a reducing region are separately arranged, and better staggered reaction can be performed on descending waste, so that reaction is complete; and the supporting base and the storage cover adopt split type design, so that better discharge effect can be achieved.

Owner:张波

Preparation method of snakehead-fishing nest-hitting bait

InactiveCN102823746AIncreased hungerImprove nesting effectAnimal feeding stuffSalvia miltiorrhizaSweet flavor

The invention relates to a preparation method of a snakehead-fishing nest-hitting bait. The bait is composed of small crucian powder, small grass carp powder, water insect powder, fish offal powder, chicken offal powder, silkworm pupa powder, lobster powder, salvia miltiorrhiza powder, hawthorn powder, garlic powder, desertliving cistanche herb powder, an edible adhesive, soybean protein powder, and milk powder. The percentages are weight percentages. With the scheme provided by the invention, when the nest-hitting bait is dropped in water, the snakehead-luring nest-hitting bait is gradually dispersed and sink, and emits a strong fishy, fragrant, and sweet flavor which is similar to a living nest-hitting bait. The bait spreads fast, such that snakeheads are turned anomaly exciting on smelling the strong fishy, fragrant, and sweet flavor; and the hunger of the snakeheads increase fast. The snakeheads come fast, and snatch violently. Therefore, fast fish accumulation, fast fish luring and good nest-hitting effect are realized.

Owner:李德卿

Casting bait for fishing catfish

InactiveCN101889651AIncreased hungerImprove nesting effectFeeding-stuffBaitCooking & bakingMarine fish

The invention discloses casting bait for fishing catfish, which is composed of green worm powder, soybean cake meal, vivipara powder, chicken meal, fuck intestine powder, marine fish powder, bone powder, fishy sachet,, hunger-accelerating agent powder for fish, feeding promoting agent for fish, appetitive agent powder for fish, adhesive powder, sweet corn protein powder and milk powder. The casting bait is prepared by a method having the following steps: combining the powder together according to the ratio; putting in a blender for stirring for 150min; taking out and then putting in a dryer, wherein the temperature of the dryer is controlled to be 55-65 DEG C, the baking time is 1-2h, and the dryness of the dried materials is controlled to be 75-85%; taking out for cooling and then putting into the blender for stirring for 140min; taking out and then putting in an bulking machine for bulking, wherein the temperature of the bulking machine is controlled to be 65-85 DEG C, and the bulking time is 1-2h and the dryness of the bulked materials are controlled to be 80-90%; and taking out for cooling and then packing.

Owner:李德卿

Convenient-to-discharge high-reliability fermentation equipment used for yogurt

The invention relates to convenient-to-discharge high-reliability fermentation equipment used for yogurt. The equipment comprises a main body, a fermentation chamber, a feeding pipe, a discharging pipe, two heaters and four supporting legs, and further comprises a discharging mechanism and two detection mechanisms; the discharging mechanism comprises a scraper blade, two driving assemblies, two lifting assemblies and two knocking assemblies; each lifting assembly comprises a first bearing, a lead screw and a sliding block; and each detection mechanism comprises a connecting pipe, a piston, twofixed plates, two first springs and two ventilation assemblies. The convenient-to-discharge high-reliability fermentation equipment used for yogurt can scrape off materials adhered to the inner wallof the fermentation chamber through the discharging mechanism, so that the discharging is convenient; through the detection mechanisms; and when the temperature in the main body is too high, ventilation of air inside and outside the main body can be realized, so that the temperature in the main body is reduced, and fermentation quality is prevented from being affected by too high temperature in the main body.

Owner:GUANGZHOU CHANXIN BIOTECH CO LTD

Screening machine facilitating screen changing

PendingCN108014997AQuick disassemblyEasy to replaceSievingScreeningAgricultural engineeringUltimate tensile strength

The invention provides a screening machine facilitating screen changing. The screening machine facilitating screen changing comprises a connection shaft, a square column type screen net, a clamping block, a clamping groove, a containing framework, a protecting box, a semicircular discharging pipe, a spiral rod and a collecting barrel; the connection shaft is installed at the left end of the containing framework; the clamping groove is machined in the side wall in the containing framework; and the clamping block is installed in the clamping groove, and is arranged at the side end of the squarecolumn type screen net which is installed in the containing framework. Due to the design, the screening function is achieved, and meanwhile, fast disassembling and assembling can also be achieved; thecollecting barrel is arranged at the lower end of the protecting box; the semicircular discharging pipe is installed at the front end of the collecting barrel, and is internally provided with the spiral rod; the collecting barrel is installed at the rear end of the spiral rod; the rear end of the spiral rod extends into the collecting barrel; due to the design, mechanical material discharging isachieved, and the labor intensity is lowered; and the screening machine facilitating screen changing improves the maintaining efficiency and the work efficiency, and is good in stability and high in reliability.

Owner:洛阳明创矿山冶金设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com