Accurate blending device for food additive

A food additive, precise technology, applied in mixers with rotary stirring devices, transportation and packaging, dissolving and other directions, can solve the problems of accurate quantitative feeding, low production efficiency, poor effect of food additives, etc., to achieve reliable stability , the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

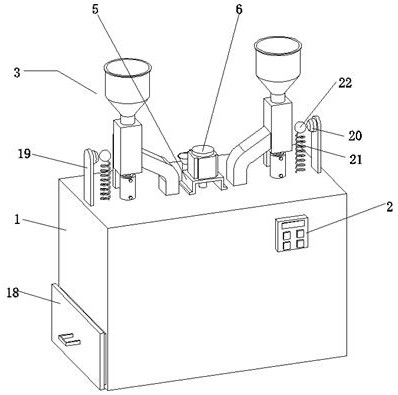

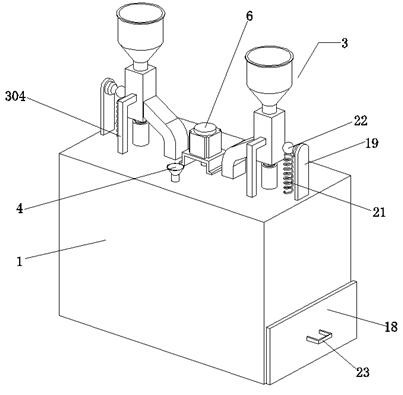

[0034] This embodiment 1 discloses a food additive precision modulation device, refer to the attached figure 1 And attached figure 2 , which includes a box body 1, a control panel 2 is arranged on the outer surface of the box body 1, and several quantitative feeding mechanisms 3 and a liquid feeding hopper 4 are arranged on the upper surface of the box body 1. Organizations can be set to 2~6.

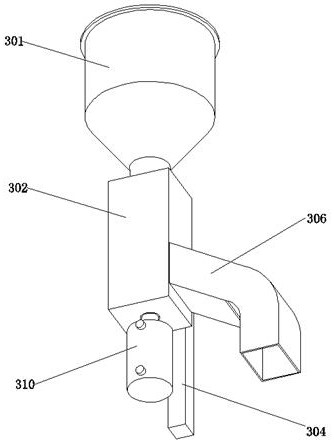

[0035] Reference attached image 3 , attached Figure 4 And attached Figure 5 , its quantitative feeding mechanism 3 includes a storage hopper 301 and a metering pipe 302, a connection pipe is connected between the storage hopper 301 and the metering pipe 302, an electric control valve 303 is arranged on the connection pipe, and its control panel 2 can control the operation of the electric control valve 303 On or off. An L-shaped fixing frame 304 is connected to the rear side of the metering tube 302, and the lower end of the L-shaped fixing frame 304 is fixedly connected to the ...

Embodiment 2

[0041] Example 2 discloses an improved food additive precision modulation device based on Example 1. Its similarities with Example 1 will not be described again. The difference is that, refer to the attached figure 1 , the present embodiment 2 is also provided with a vertical strip 19 on the upper surface of the casing 1 positioned at each quantitative feeding mechanism 3 side, and the vertical strip 19 is provided with an electromagnet 20 facing the side of the metering tube 302, and at the same time, it is positioned at the quantitative feeding mechanism. Elastic piece 21 is connected with 19 between mechanism 3 and vertical bar, and its elastic piece can be selected elastic strip or spring for use, then is connected with knocking block 22 at the upper end of elastic piece 21, and this knocking piece 22 is iron block or magnet block . When the electromagnet 20 is energized, the knocking block 22 can be adsorbed, and then the knocking block 22 moves to the metering tube 302 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com