Gas component qualitative and quantitative detection analysis device and method

A technology for quantitative detection and gas composition, which can be used in measurement devices, analytical materials, material separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

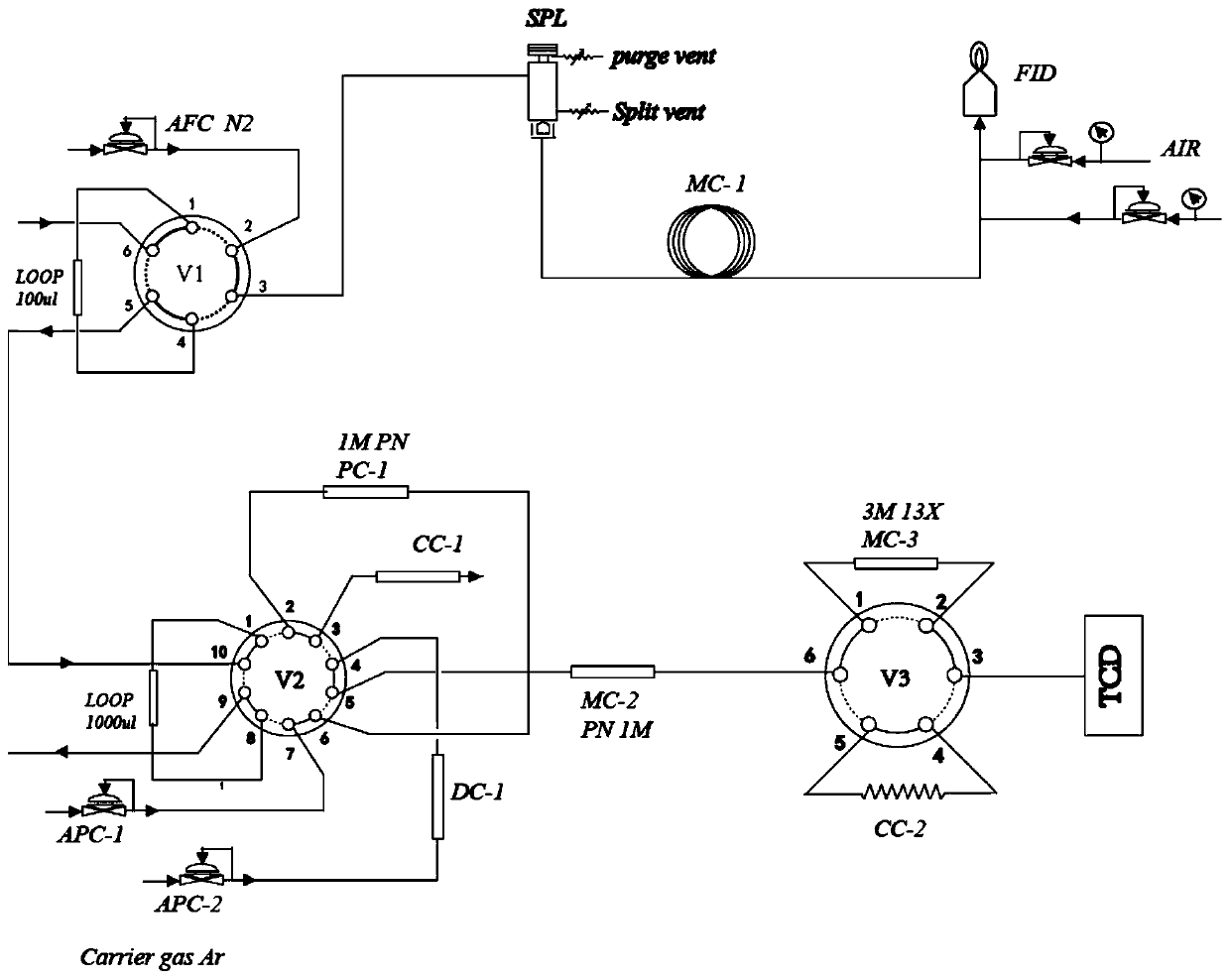

[0070] This embodiment provides a qualitative and quantitative detection and analysis device for gas components. The device includes a first inlet for the gas to be tested, an outlet for the gas to be tested, a first carrier gas inlet, a second carrier gas inlet, and a third carrier gas inlet. , the first quantitative loop, the second quantitative loop, the first six-port valve, the second six-port valve, the ten-port valve, the FID detector, the TCD detector, the first damping tube, the second empty chromatographic column, the first preset A separation column, a second pre-separation column, a first chromatographic column, a second chromatographic column, and pipelines connecting the components;

[0071] The first gas inlet to be tested is connected to the first end of the first quantitative loop through the first six-way valve, and the second end of the first quantitative loop is connected to the second quantitative loop through the first six-way valve and the ten-way valve. ...

Embodiment 2

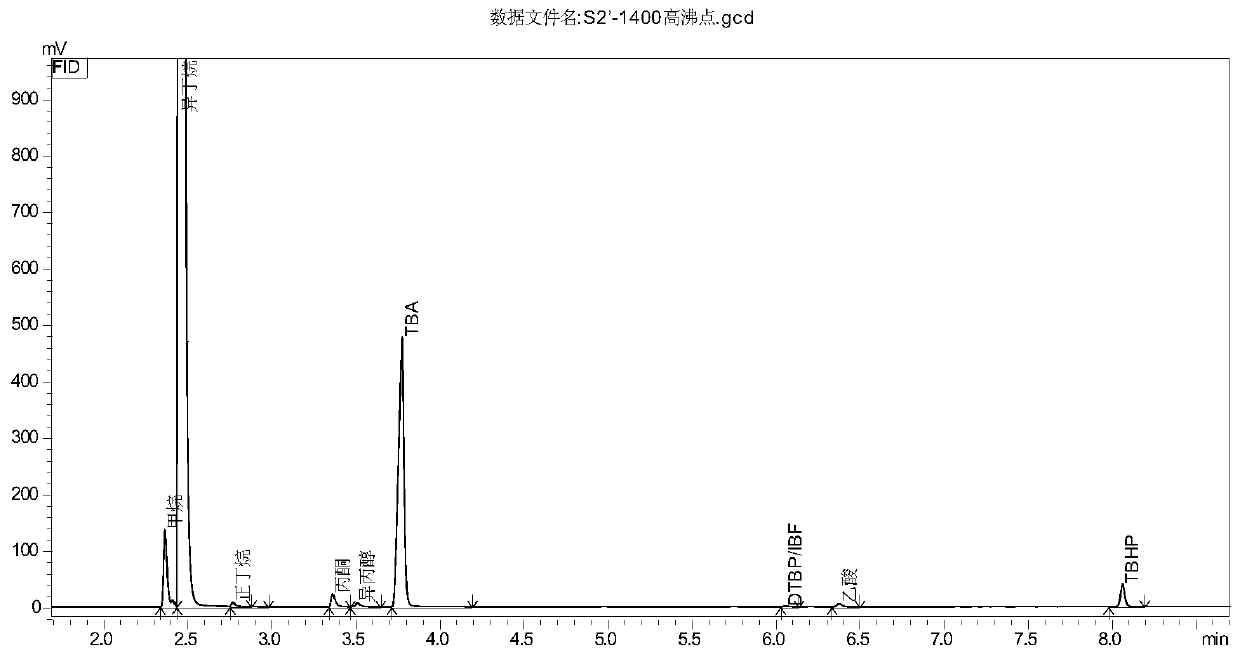

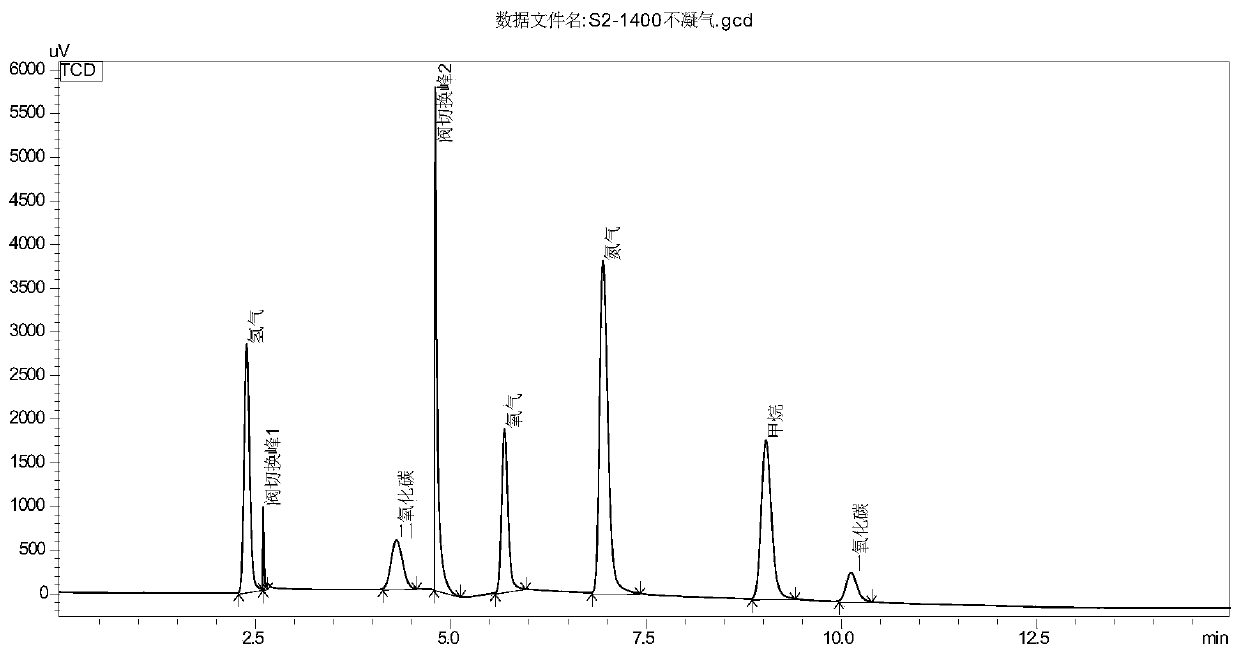

[0088] This embodiment provides a method for qualitative and quantitative detection and analysis of gas components, the method is based on the analysis device of the above-mentioned embodiment, and the method includes the following steps:

[0089] 1) Adjust the port status of the first six-way valve and the ten-way valve so that the first six-way valve and the ten-way valve are connected in series, and the gas to be tested is sent into the first gas to be tested inlet, and the gas to be tested passes through the first gas to be tested sequentially. Port 6A and port 1A of the six-way valve enter the first quantitative loop for loading, and after loading, pass through port 4A of the first six-way valve, port 5A of the first six-way valve, and port 10 of the ten-way valve in sequence. Port 10B and port 1B of the ten-way valve enter the second quantitative loop for loading. After loading, the excess gas to be tested is discharged from the outlet of the gas to be tested through port...

Embodiment 3

[0097] This embodiment provides a qualitative and quantitative detection and analysis device for gas components. Carrier gas inlet, first quantitative loop, second quantitative loop, first six-way valve, second six-way valve, ten-way valve, FID detector, TCD detector, first damping tube, first empty chromatographic column, The second empty chromatographic column, the first pre-separation column, the second pre-separation column, the first chromatographic column, the second chromatographic column, and the pipelines connecting the components;

[0098] The first six-way valve includes port 1A, port 2A, port 3A, ..., port 6A in the clockwise direction, and the ten-way valve includes port 1B and port 2B in the clockwise direction , port 3B, ..., port 10B; the second six-way valve is recorded as port 1C, port 2C, port 3C, ..., port 6C in a clockwise direction;

[0099] The first gas inlet to be tested is connected to the first end of the first quantitative loop through port 6A and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com