Calibration plate, calibration plate identification method and calibration plate identification device

A technology for calibration boards and recognition results, applied in image data processing, instruments, calculations, etc., can solve problems such as limited applicable scenarios, and achieve the effects of reducing interference, improving recognition accuracy, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

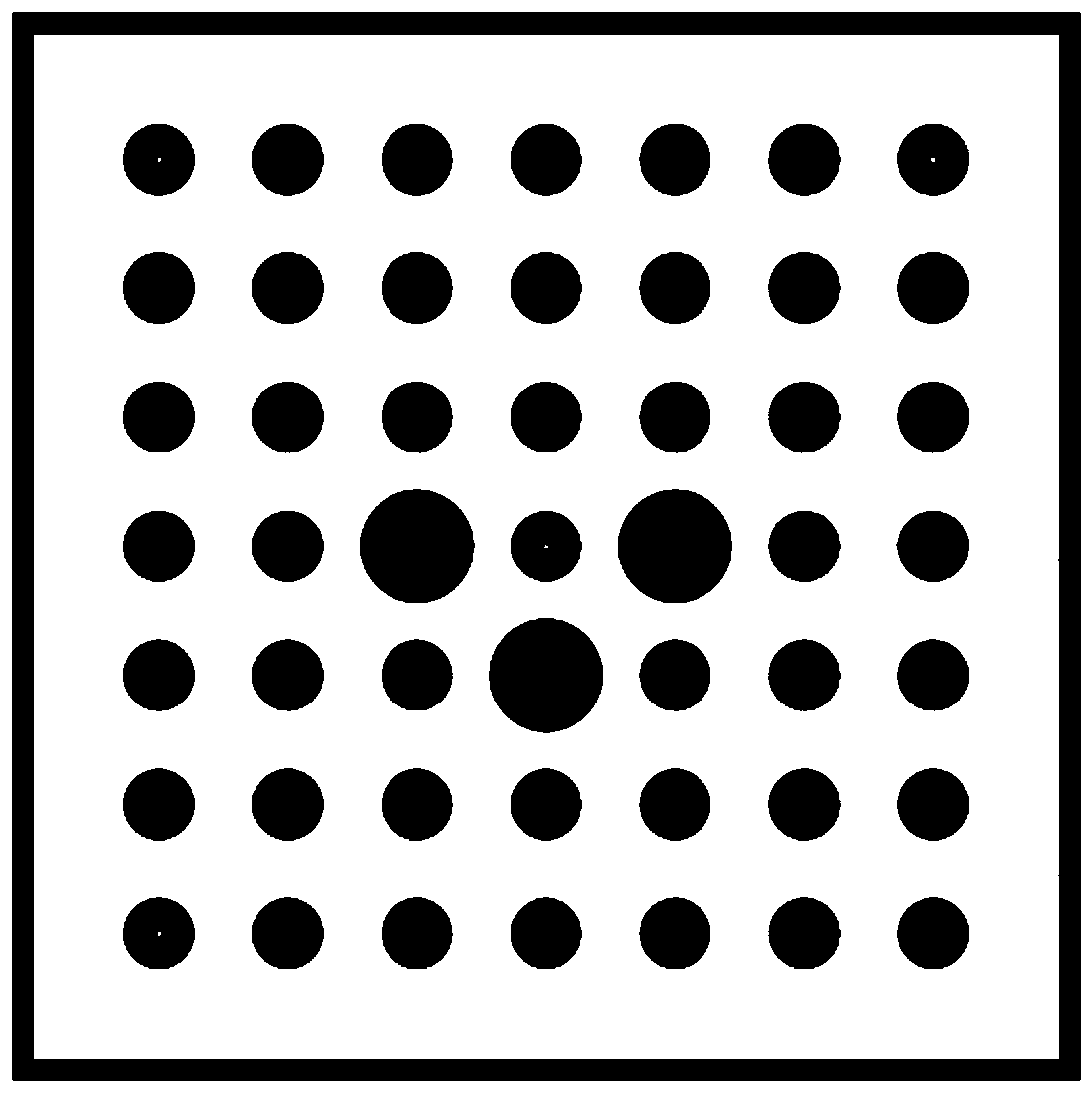

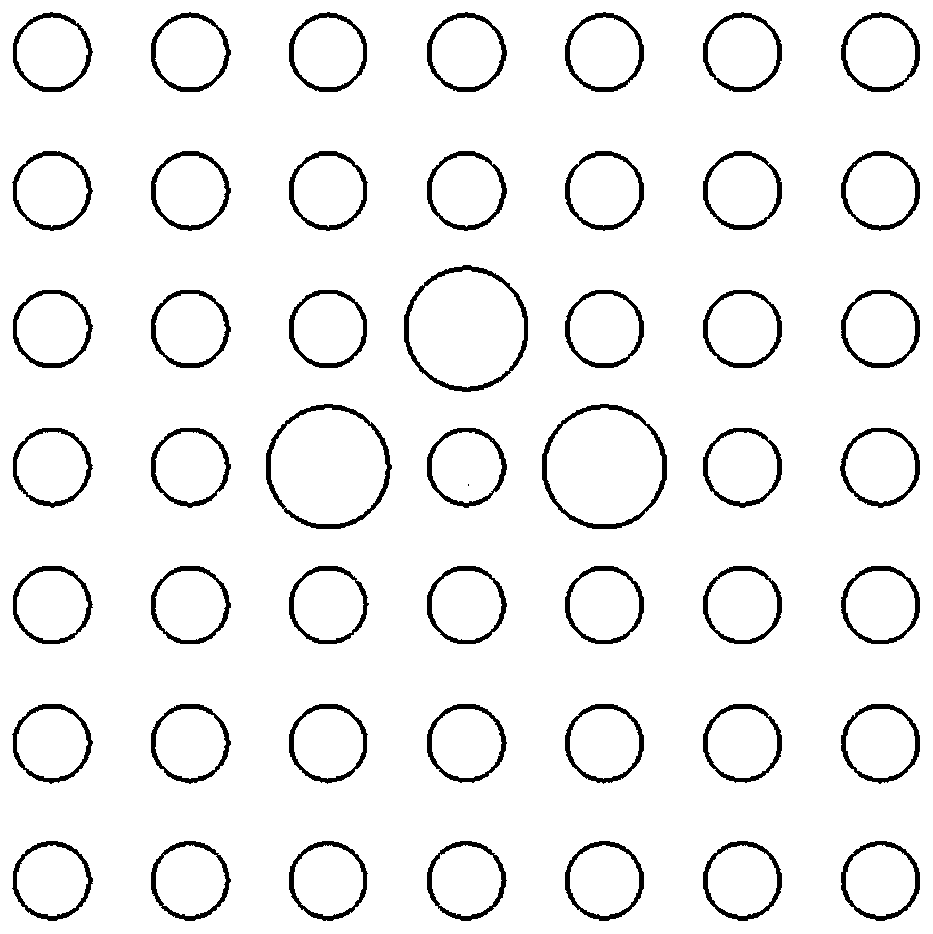

[0030] Embodiment 1 of the present invention provides a calibration plate, see figure 1 The schematic diagram of the calibration board structure shown, the calibration board includes:

[0031](1) The calibration board is a plane calibration board; the calibration board is provided with characteristic dots arranged at equal intervals in a matrix; the characteristic dots are all arranged inside the outer frame.

[0032] Set characteristic dots arranged at equal intervals in n rows and m columns on the flat calibration board, the distance between adjacent circle centers can be set to 1 (the unit can be determined according to actual needs), and the dot radius is about 1 / 4. Feature dots can be printed on specific materials, such as paper, glass, ceramics, aluminum, film, etc. Different materials can have a variety of different printing processes (such as photolithography, laser engraving, light painting, laser printing, etc.).

[0033] The characteristic dots provide the most fu...

Embodiment 2

[0045] Embodiment 2 of the present invention provides a calibration plate identification method, see Figure 5 The schematic diagram of the flow chart of the calibration plate identification method shown in the method, the method includes the following steps:

[0046] Step S502, acquiring the target image captured by the camera including the calibration plate as in Embodiment 1;

[0047] The camera may be a camera to be calibrated. The target image is an image including a complete calibration plate image as in Example 1 or an image including a part of the calibration plate as in Example 1. Part of the reference plate may be, for example, a reference plate whose edge is partially blocked.

[0048] Step S504, determine the position of the calibration board in the target image, and determine the estimated position and world coordinate system position of each dot in the calibration board area according to the marked characteristic dots;

[0049] The position of the calibration ...

Embodiment 3

[0070] Embodiment 3 of the present invention provides a calibration plate identification device, see Image 6 The schematic block diagram of the structure of the calibration plate identification device shown, the device includes:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com