A kind of heart valve modified by hydrophilic composite network laminate and its preparation method

A composite network and heart valve technology, applied in coatings, pharmaceutical formulations, prostheses, etc., can solve the problems of biological valves prone to thrombus, early failure, calcification, etc., to reduce the formation of thrombus and calcified spots, and prevent calcification and early failure, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

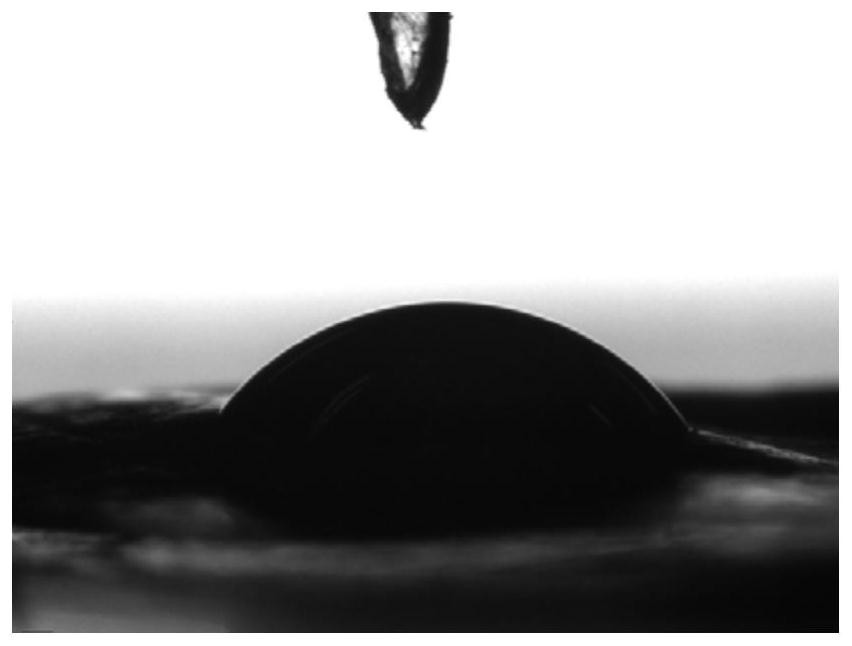

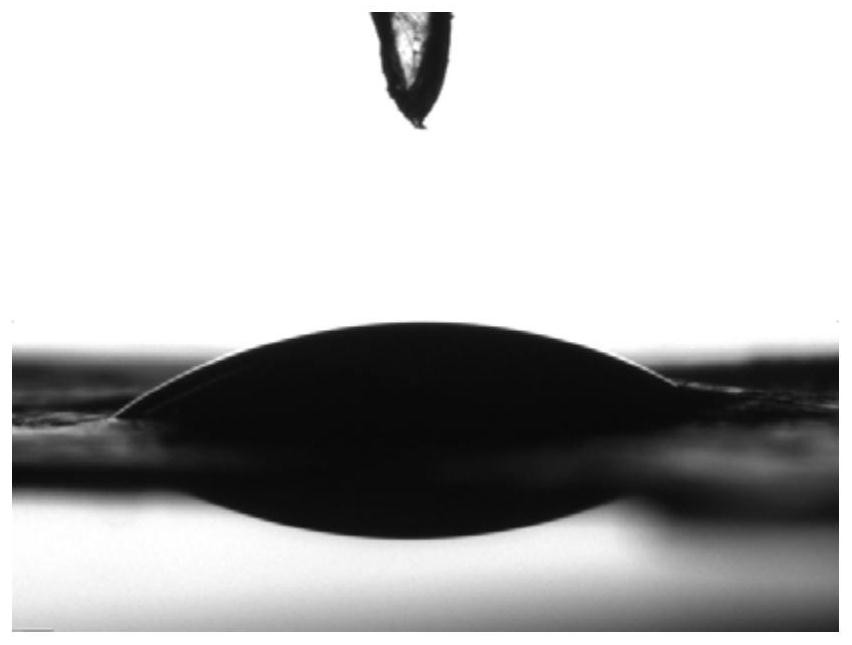

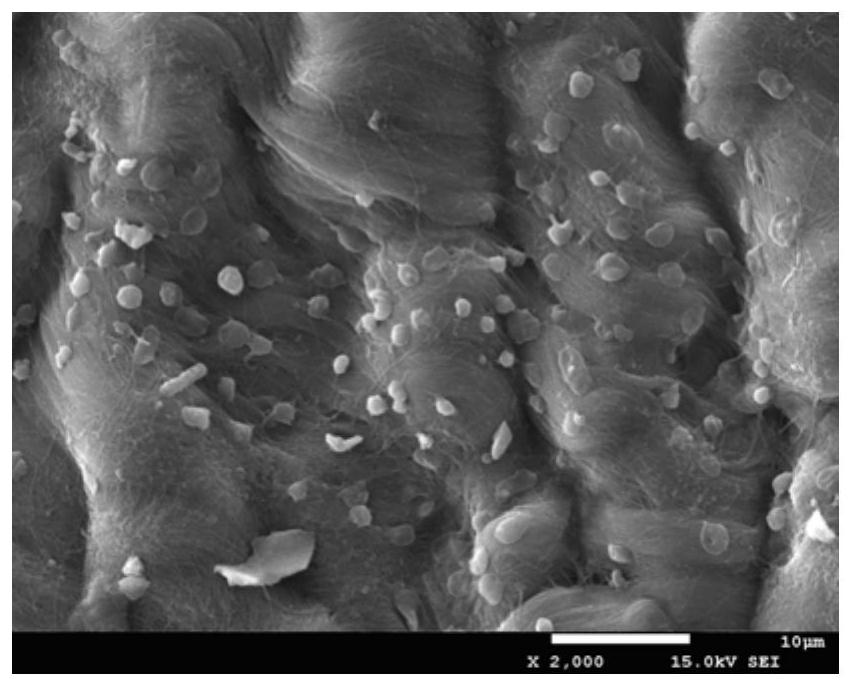

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of mixed dispersions of water-based polymers / hydrophilic inorganic nanoparticles in different proportions

[0036] Low molecular weight and low concentration polymer mixed dispersion (PVA+PEG+1:3 silica) A: the selected molecular weight is ~5*10 3 g / mol and ~1*10 4 PEG and PVA of g / mol were dissolved in water respectively to form a mixed solution, and further 50nm silicon dioxide was added to the solution in a ratio of 1:3 to prepare a mixed dispersion A, wherein the concentrations of PEG and PVA were both 0.1wt%, for later use ;

[0037] Low-molecular-weight high-concentration polymer mixed dispersion (PEG+PAA+1:3 silica) B: the selected molecular weight is ~5*10 3 g / mol and ~1*10 4 g / mol PEG and PAA were respectively dissolved in water to form a mixed solution, and silicon dioxide was further added to the solution at a ratio of 1:3 to prepare a mixed dispersion A: the concentrations of PEG and PVA were both 2.5wt% for later use;

[0038] High molec...

Embodiment 2

[0044] (1) Preparation of mixed dispersions of water-based polymers / hydrophilic inorganic nanoparticles in different proportions

[0045] Low molecular weight and low concentration polymer mixed dispersion (PVA+PEG+1:3 hydroxyapatite) A: the selected molecular weight is ~5*10 3 g / mol and ~1*10 4 The PEG and PVA of g / mol were respectively dissolved in water to form a mixed solution, and 50nm hydroxyapatite was further added to the solution in a ratio of 1:3 to prepare a mixed dispersion A, wherein the concentrations of PEG and PVA were both 0.1wt%, spare;

[0046] Low-molecular-weight high-concentration polymer mixed dispersion (PEG+PAA+1:3 hydroxyapatite) B: the selected molecular weight is ~5*10 3 g / mol and ~1*10 4 g / mol PEG and PAA were dissolved in water to form a mixed solution, and 50nm hydroxyapatite was further added to the solution at a ratio of 1:3 to prepare a mixed dispersion A: the concentrations of PEG and PVA were both 2.5wt%, spare;

[0047] High molecular ...

Embodiment 3

[0053] (1) Preparation of mixed dispersions of water-based polymers / hydrophilic inorganic nanoparticles in different proportions

[0054] Low molecular weight and low concentration polymer mixed dispersion (PVA+PEG+1:2.5 calcium silicate) A: the selected molecular weight is ~8*10 3 g / mol and ~5*10 3 PEG and PVA of g / mol were respectively dissolved in water to form a mixed solution, and further 200nm calcium silicate was added to the solution in a ratio of 1:2.5 to prepare a mixed dispersion A, wherein the concentrations of PEG and PVA were both 0.7wt%, for later use ;

[0055] Low-molecular-weight high-concentration polymer mixed dispersion (PAA+PEG+1:2.5 calcium silicate) B: The selected molecular weights are ~~8*10 3 g / mol and ~5*10 3 PEG and PAA of g / mol were dissolved in water respectively to form a mixed solution, and further 200nm calcium silicate was added to the solution at a ratio of 1:2.5 to prepare a mixed dispersion A: the concentrations of PEG and PVA were both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com