A bionic micro-nano laminated hydrophobic biological valve and its preparation method

A biological valve, micro-nano lamination technology, applied in the direction of coating, drug delivery, tissue regeneration, etc., can solve the problems of prone to thrombus and calcification, reduce the formation of thrombus and calcification spots, good blood compatibility, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

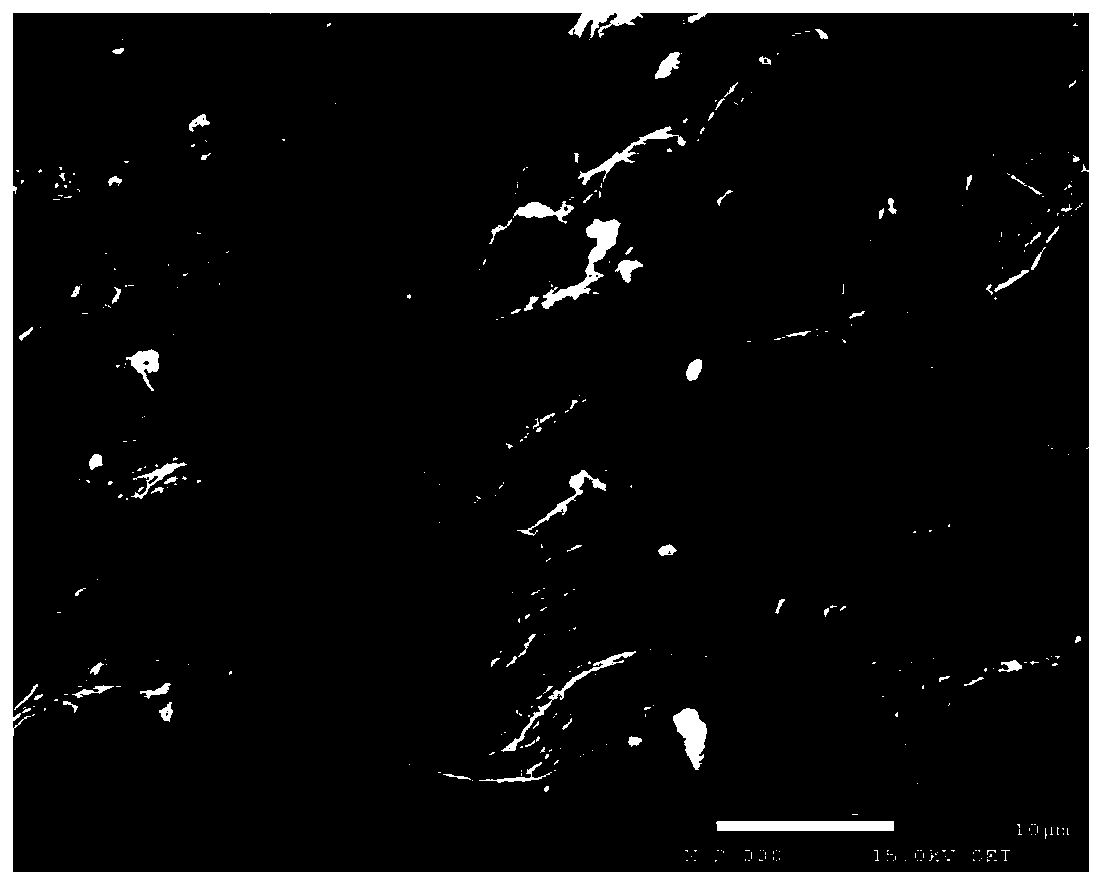

Image

Examples

Embodiment 1

[0038] (1) Selection and modified pretreatment of biological valves and inorganic nanoparticles

[0039] Cross-linking treatment of biological valves: Freshly collected porcine pericardium was repeatedly washed with deionized water at 4°C and 100 rpm for 2 hours, then soaked in 0.6wt% glutaraldehyde for 24 hours; rinsed with deionized water at least 5 times, and then used;

[0040] Pretreatment of biological valves: Soak the porcine pericardium after cross-linking and fixing with ethanol for 90 minutes, then soak and rinse with deionized water for at least 3 times, and dry at 80°C for 4 hours; then use 1.0wt% 3-glycidol Soak in etheroxypropyl trimethoxysilane for more than 30 minutes, and place it at 80°C for 1 hour to obtain a pretreated biological valve;

[0041] Pretreatment of silica: Soak 50nm silica in ethanol for 90min, soak and rinse with deionized water for at least 3 times, and dry at 80°C for 4h; then use 1.0wt% 3-glycidyl ether oxygen Soak in propyltrimethoxysilan...

Embodiment 2

[0050] (1) Selection and modified pretreatment of biological valves and inorganic nanoparticles

[0051] Cross-linking treatment of biological valves: Freshly collected bovine pericardium was repeatedly washed with deionized water at 4°C and 100 rpm for 2 hours; then soaked in 0.6wt% glutaraldehyde for 24 hours; rinsed with deionized water for at least 5 times, and set aside;

[0052] Pretreatment of biological valves: Soak the bovine pericardium after cross-linking and fixation with ethanol for 60 minutes, then soak and rinse with deionized water for at least 3 times, and dry at 70°C for 6 hours; then use 1.5wt% bis(dioctyl Soak in oxypyrophosphate) ethylene titanate for 45 minutes, and react at 70°C for 1.5 hours;

[0053] Pretreatment of silicon dioxide: soak 100nm silicon dioxide in ethanol for 90 minutes, soak and rinse with deionized water for at least 3 times, and dry at 80°C for 4 hours; then use 2wt% bis(dioctyloxycoke Phosphate-based) ethylene titanate soaked for 45...

Embodiment 3

[0068] (1) Selection and modified pretreatment of biological valves and inorganic nanoparticles

[0069] Cross-linking treatment of biological valves: Freshly collected bovine pericardium was repeatedly washed with deionized water at 4°C and 100 rpm for 2 hours; then soaked in 4.0wt% paraformaldehyde for 4 hours; rinsed with deionized water for at least 5 times, and set aside;

[0070]Pretreatment of biological valve: Soak the cross-linked and fixed bovine pericardium with ethanol for 120 minutes, then soak and rinse with deionized water for at least 3 times, and dry at 60°C for 24 hours; then use 3.0wt% 3-aminopropanol Soak in triethoxysilane for 60 minutes, and react at 60°C for 3 hours;

[0071] Pretreatment of titanium dioxide: first soak 50nm titanium dioxide in ethanol for 120min, then soak and rinse with deionized water for at least 3 times, and dry at 60°C for 24h; then use 2.5wt% 3-aminopropyltriethoxysilane Soak for more than 30min, and place it at 60°C for 3h.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com