Ox horn type ageing equipment automatic lifting static testing device

A technology of static testing and aging equipment, applied in sorting and other directions, can solve the problems of low test accuracy, achieve the effect of solving low test accuracy, reducing labor costs, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the concrete structure of the present invention is as follows:

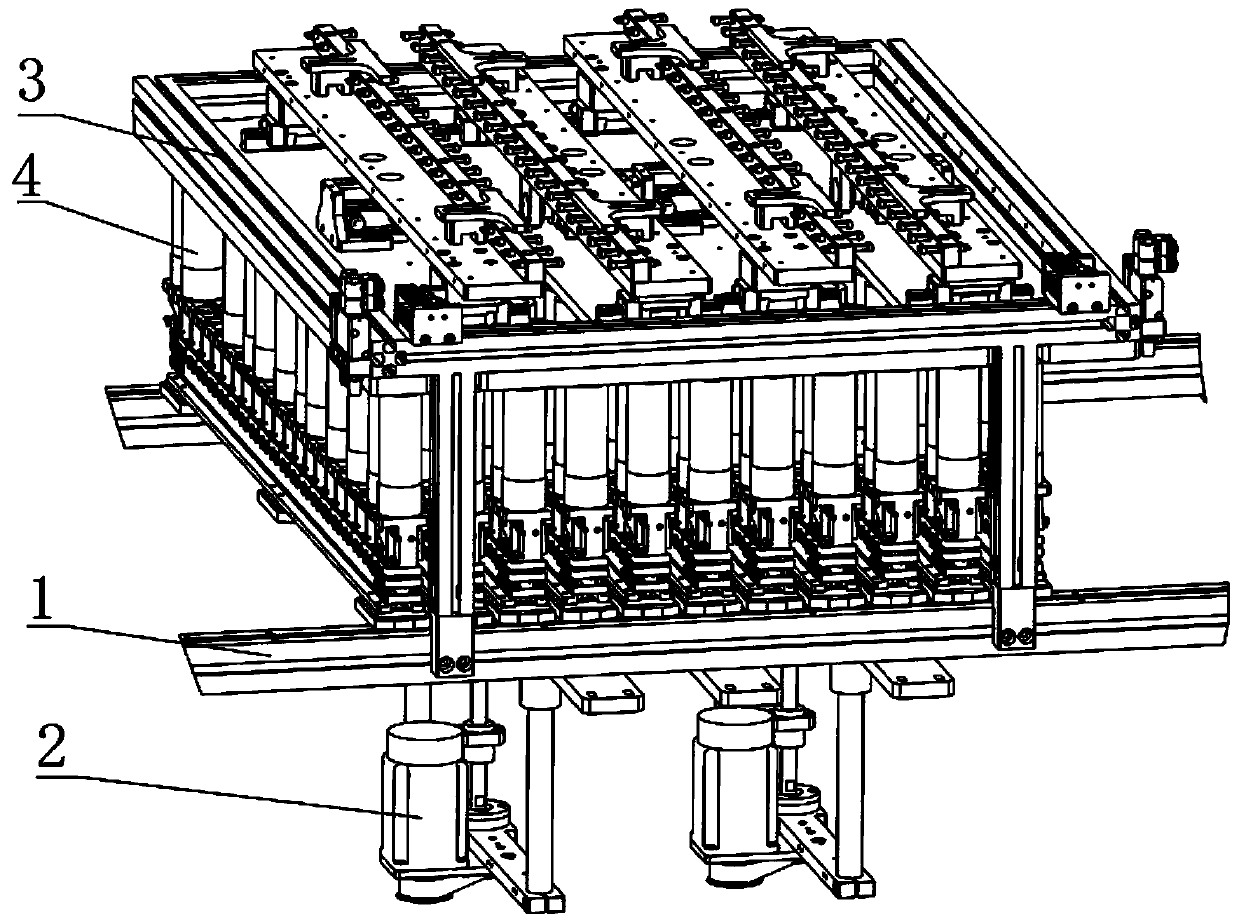

[0030] Please refer to attached Figure 1-10 , the automatic lifting static test device of a kind of horn type aging equipment of the present invention, comprises frame 1, and the middle part of frame body of described frame 1 is provided with multiple rows of carrier stations for loading products, and the automatic lifting static The test set also includes:

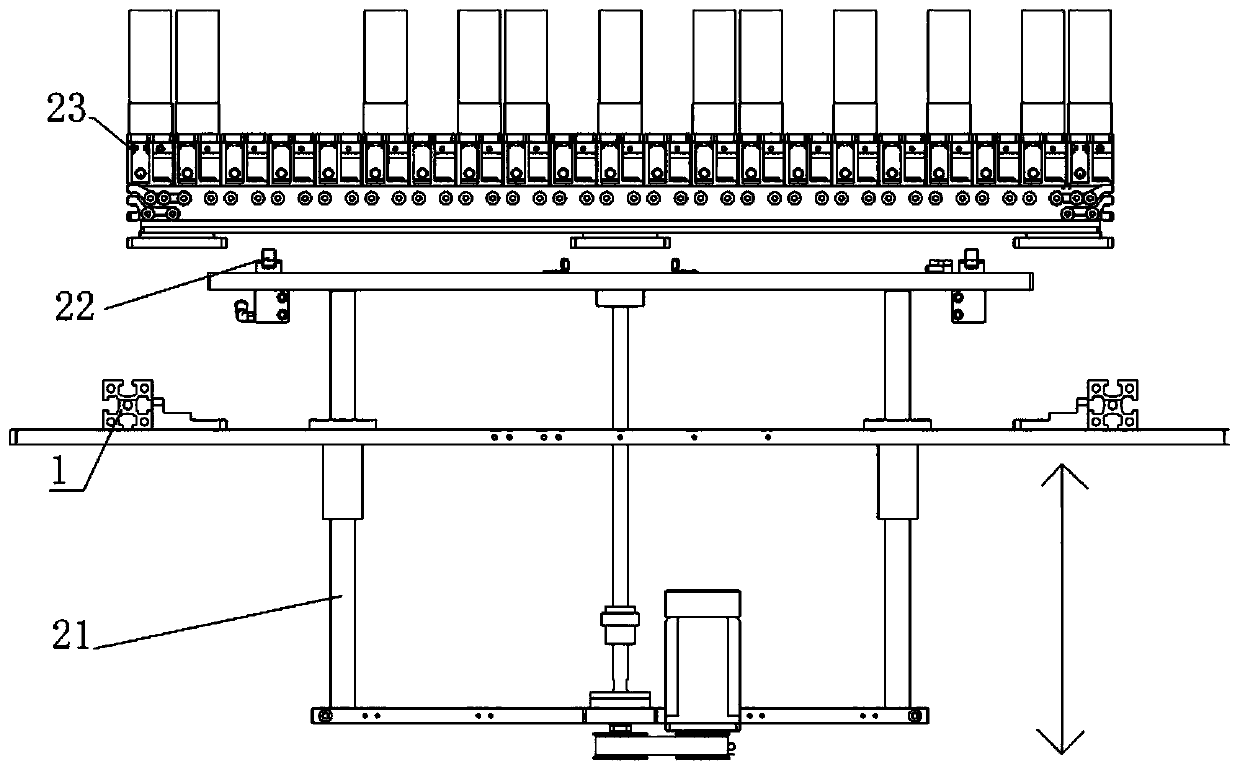

[0031] The lifting and clamping mechanism 2 is arranged below the frame 1 and includes a lifting mechanism and a clamping mechanism arranged on the lifting mechanism. The clamping mechanism lifts the product 4 on the carrier station through the lifting of the lifting mechanism. Move up to the station to be tested;

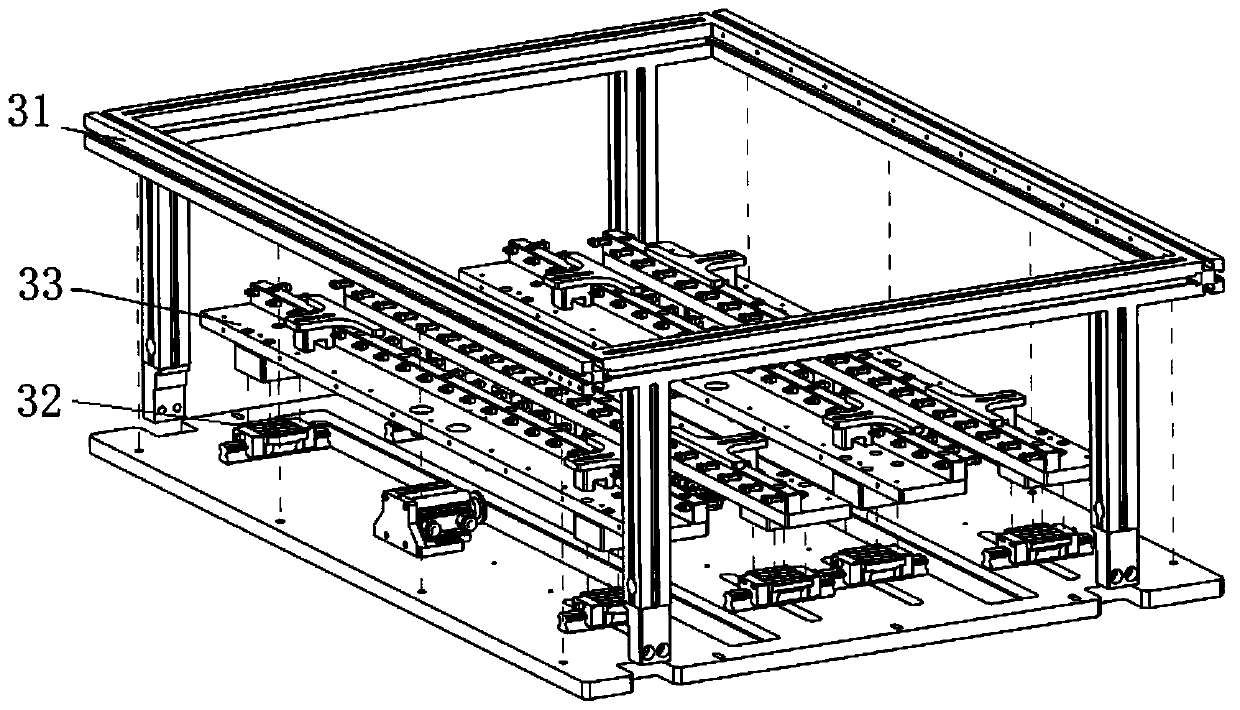

[0032] The static testing device 3 is arranged on the top of the frame 1 and placed above the lifting and clamping mechanism 2, on which is provided a static testing assembly for static testing of the product 4 on the test...

Embodiment 2

[0040] Embodiment 2: operating principle of the present invention is as follows:

[0041] 1. The aging fixture 23 clamps the product 4, and then is sent to the holding device 22 by the conveying assembly along the conveying direction A to prepare for testing, and then the holding device 22 clamps the aging fixture 23, such as Figure 7 shown. After that, the two lifting devices 21 send the clamping device 22 and the aging jig 23 vertically upward to the station to be tested.

[0042] 2. After the product 4 is sent to the station to be tested, the test cylinders 323 on the left and right sides of the long via hole on the test base plate 321 push the test push plate 331 to move toward each other through the push-and-displacement connecting block 333 . Such as Figure 8 As shown, when the probe 337 touches the moving clip block on the corresponding aging fixture 23 and presses it tightly, the product 4 is tested, and the test result is transmitted to each instrument.

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com