Laser cutting working platform

A working platform and laser cutting technology, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of ignoring positioning, reducing production efficiency, and increasing the scrap rate of workpieces, so as to achieve precise cutting, improve production efficiency, Effect of reducing workpiece rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

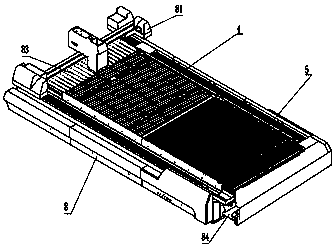

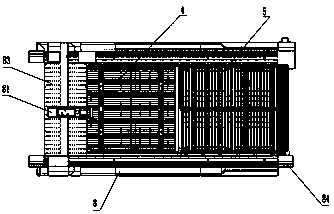

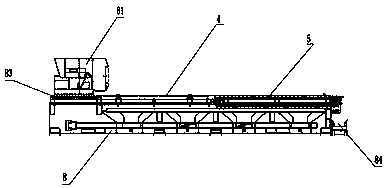

[0039] The laser cutting working platform of the present invention is as Figure 1-3 As shown, a main bed 8 is provided and a clean material cutting area 4 and a rotating table 5 are provided from back to front, and the clean material cutting area 4 and the rotating table 5 are fixed together on the main bed 8 of the laser cutting work platform , the main bed 8 is also provided with a laser cutting head assembly 81, the laser cutting head assembly 81 is placed above the clean material cutting area 4 and the rotating table 5; during specific implementation, the laser cutting head assembly 81 can move;

[0040] Such as Figure 4-5 with Figure 8 As shown, the clean material cutting area 4 is provided with more than two clean material cutting support strips 41, a clean material cutting servo motor 42 and a stop mount; the left and right ends of the stop mount are bolted to the main bed 8 On the top, there are two stop mounts arranged symmetrically along the longitudinal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com