Shuttle vehicle shifting lever module, extending fork module and walking assembly and logistics shuttle vehicle

A shuttle car and assembly technology, applied in the field of automatic storage equipment, can solve the problems of slow walking acceleration, difficult installation, complex structure, etc., and achieve the effect of improving walking acceleration, light weight of the overall structure, and simple composition structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

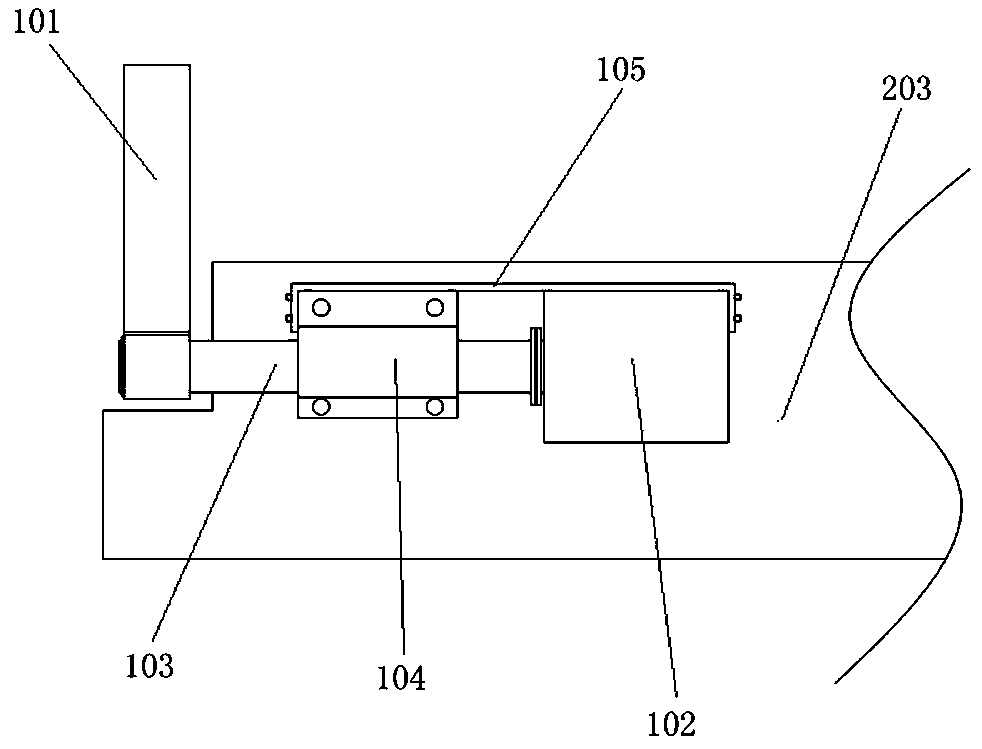

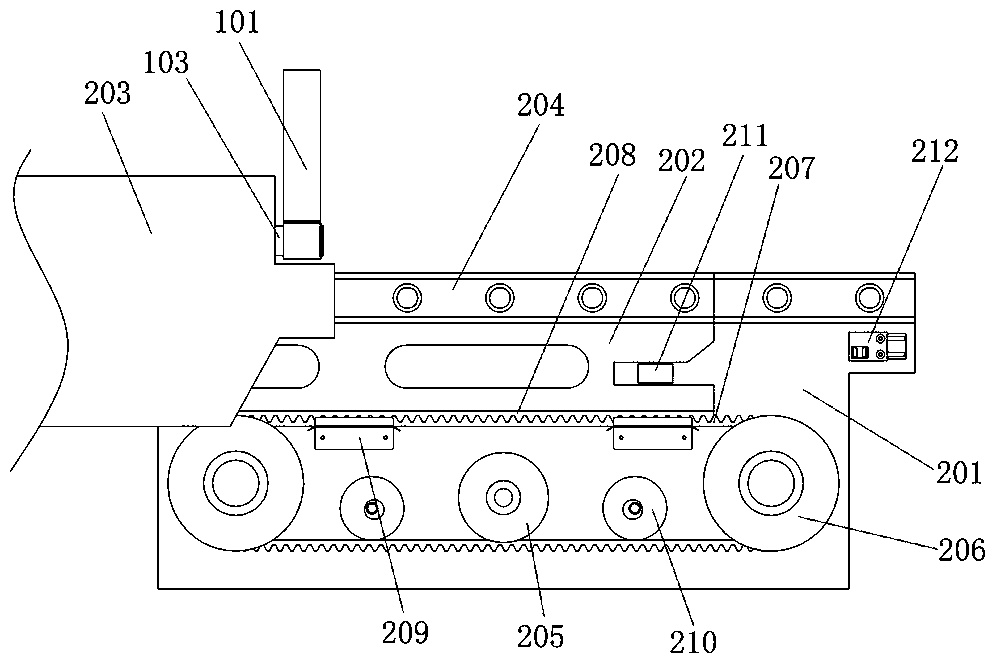

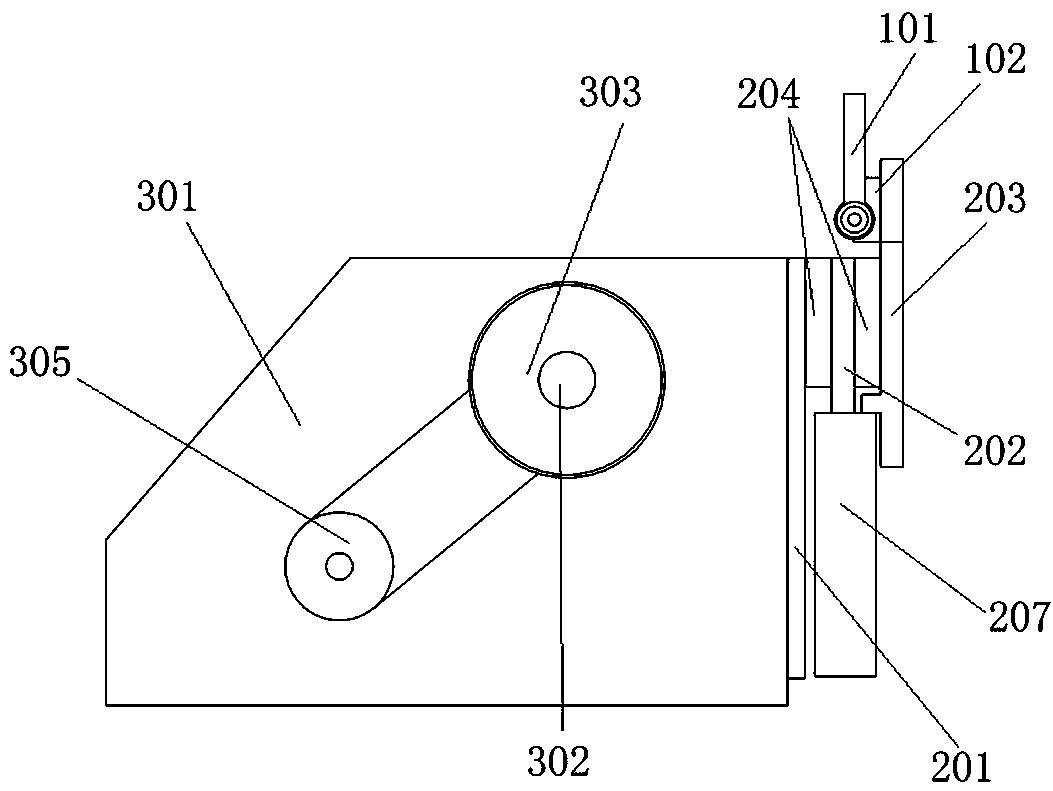

[0040] like figure 1 As shown, this embodiment provides a shuttle lever module, which includes a long straight rod-shaped lever 101, a rotary driver 102 composed of a corner cylinder or a servo motor or other devices that can realize fixed-angle steering, and two ends The above-mentioned lever 101 and the transmission shaft 103 of the rotary driver 102 are respectively coupled through a coupling or a pin shaft. The rotary driver 102 is electrically connected to a metal core optical tape, and the metal core optical tape is a glass fiber optical fiber with an internal metal core wire. bring. It is used to replace the multiple signal lines and power supply lines wrapped by tank drive chains or towlines in the general prior art: that is, its optical fibers can provide signals for controlling the movement of the rotating drive 102, and the metal core wires can be used for The opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com