Sludge drying device and sludge drying method

A sludge drying and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of small contact area between sludge and air, affecting water evaporation efficiency, increasing sludge and air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the present invention, unless otherwise stated, the used orientation words such as "up, down, left, right" usually refer to the orientations shown in the accompanying drawings, and "inside and outside" refer to the outline of the parts. inside and outside.

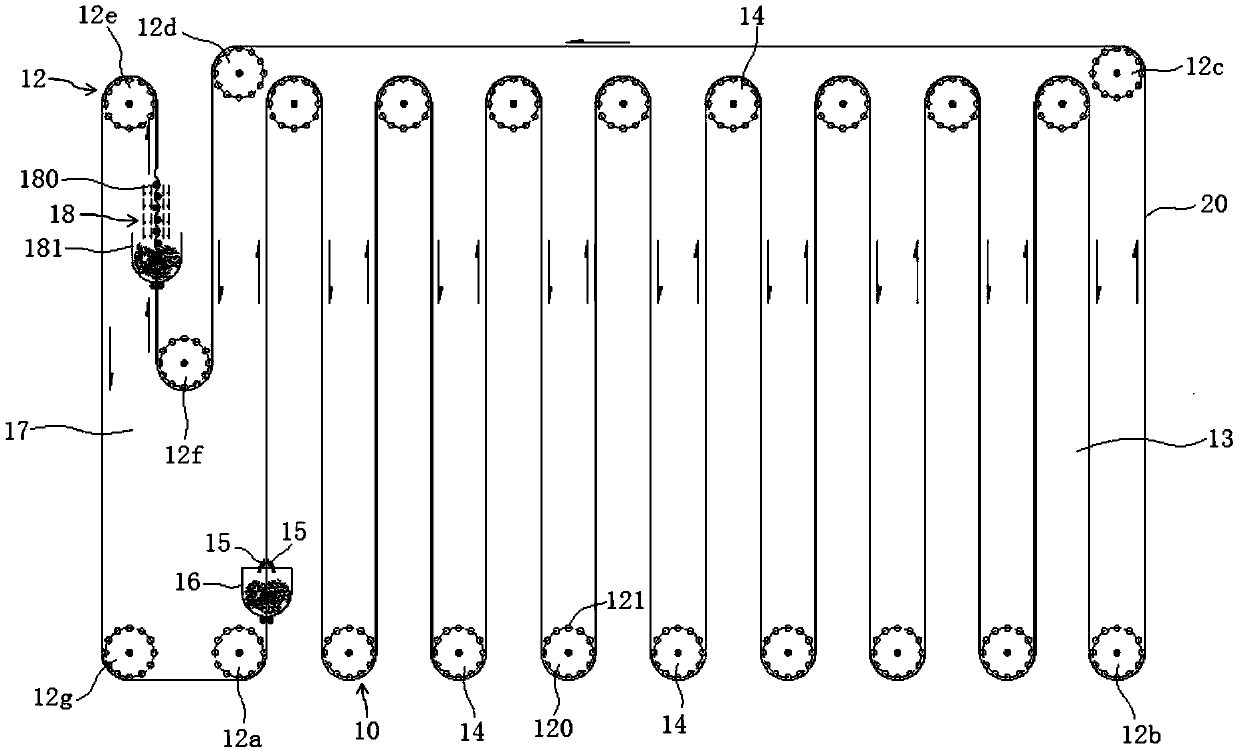

[0029] The present invention provides a sludge drying device, the sludge drying device includes a transmission mechanism 10, the transmission mechanism 10 includes a plurality of support rollers 12, each support roller 12 can rotate around the central axis of the support roller 12, The sludge drying device further includes a conveyor belt 20, at least one side of the conveyor belt 20 can be covered with sludge, and the conveyor belt 20 is wound around a plurality of support rollers 12 to form a closed conveyor path. By winding the conveyor belt 20 around a plurality of support rollers 12, and making the conveyor belt 20 form a closed transmission path, at the same time, the sludge can be attached to at least one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com