Cement stabilized mixture and preparation method thereof

A cement stabilization and mixing technology, applied in the field of building materials, can solve problems such as polluting the environment and destroying ecological balance, and achieve the effects of solving environmental pollution, saving resources, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

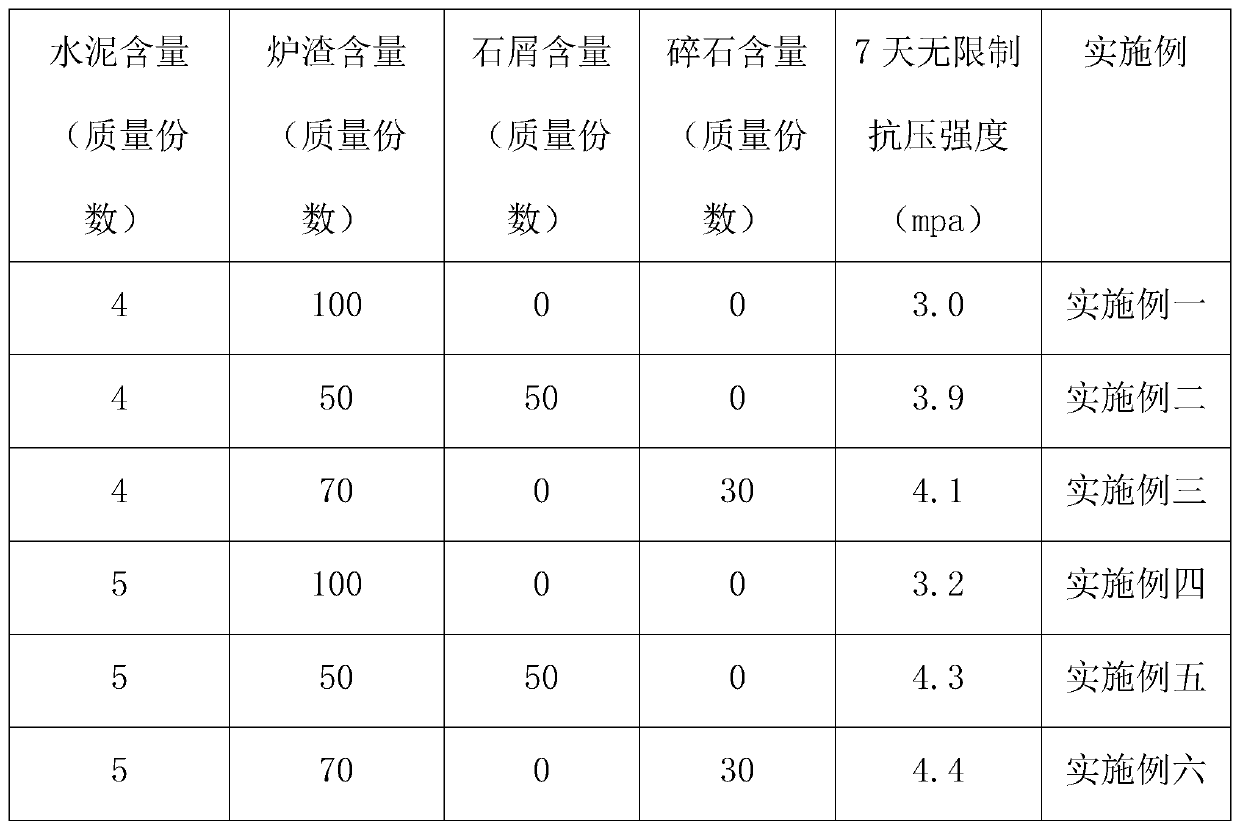

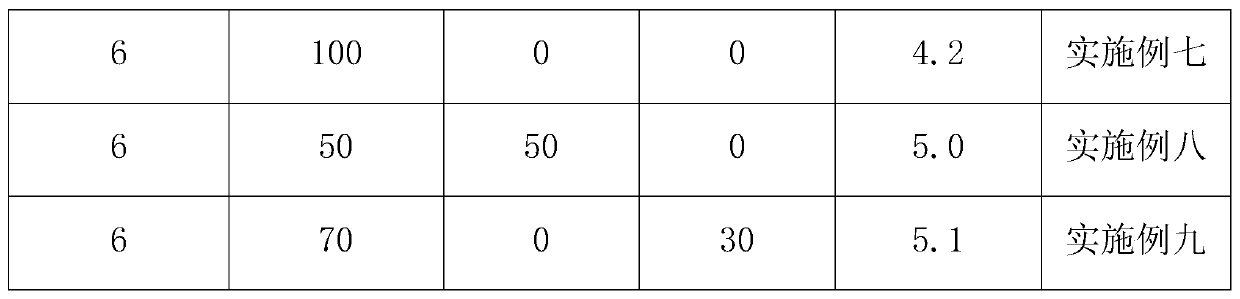

[0017] A cement stabilized mixture, the mixture is composed of cement, slag, stone chips and crushed stone; the weight parts of each component of the mixture are 4 parts of cement, 100 parts of slag, 0 parts of stone chips and 0 parts of crushed stone The slag is waste slag formed after the domestic waste is put into the thermal power plant for incineration and power generation, and then the waste slag is screened and purified to obtain the slag. The stone chips are powder obtained after crushing construction waste or stone chips produced in a quarry.

Embodiment 2

[0019] A cement stabilized mixture consisting of cement, slag, stone chips and crushed stone; the weight parts of each component of the mixture are 4 parts of cement, 50 parts of slag, 50 parts of stone chips, and 0 parts of crushed stone The slag is waste slag formed after the domestic waste is put into the thermal power plant for incineration and power generation, and then the waste slag is screened and purified to obtain the slag. The stone chips are powder obtained after crushing construction waste or stone chips produced by a quarry.

Embodiment 3

[0021] A cement stabilized mixture consisting of cement, slag, stone chips and crushed stone; the weight parts of each component of the mixture are 4 parts of cement, 70 parts of slag, 0 parts of stone chips and 30 parts of crushed stone The slag is waste slag formed after the domestic waste is put into the thermal power plant for incineration and power generation, and then the waste slag is screened and purified to obtain the slag. The stone chips are powder obtained after crushing construction waste or stone chips produced in a quarry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com