Preparation method of self-repairing non-isocyanate polyurethane

A non-isocyanate, polyurethane technology, applied in the field of polyurethane, can solve problems such as environmental and human health hazards, and achieve the effects of easy operation, excellent mechanical properties, and excellent self-healing properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

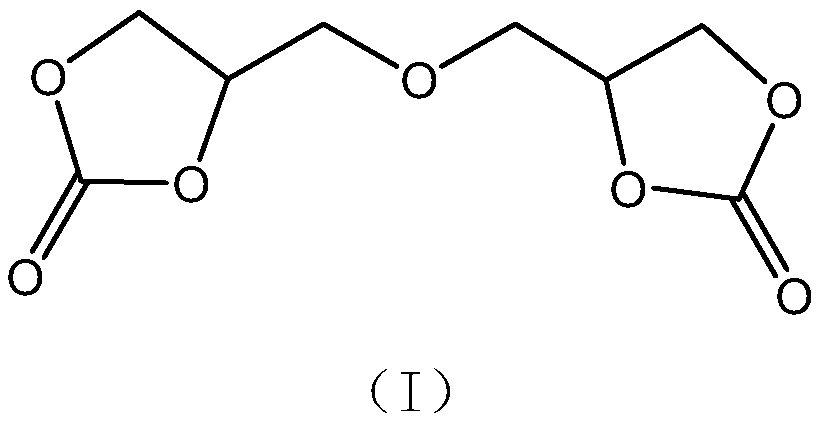

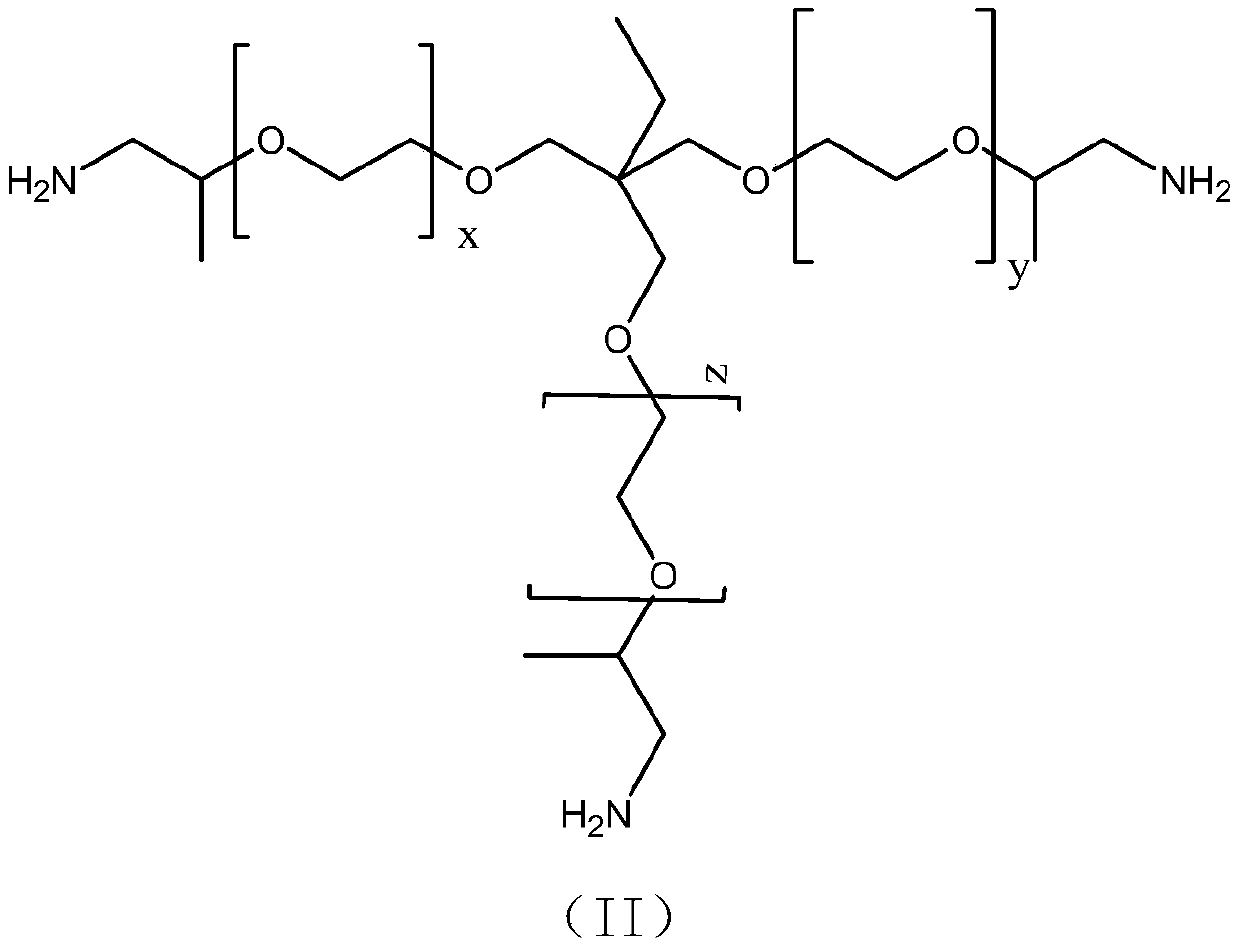

[0032] 1) Preparation of furan ring-terminated non-isocyanate polyurethane prepolymer: Weigh 1 part of polyether triamine, 3 parts of diglycerol bicyclic carbonate, and 3 parts of furan methylamine in molar fractions, and react at 70°C for 8 hours to obtain Furan ring-terminated non-isocyanate polyurethane prepolymer M-NIPU-1 with polyethertriamine as the core;

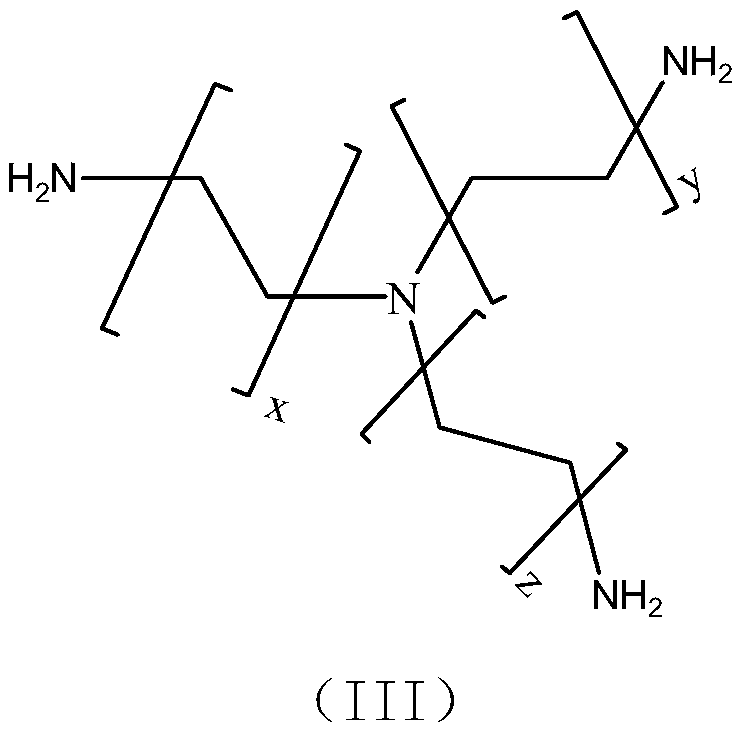

[0033] 2) Weigh 1 part of aliphatic triamine, 3 parts of diglycerol bicyclic carbonate, and 3 parts of furyl methylamine in molar fractions, and react at 70°C for 8 hours to obtain a furan ring-terminated non- Isocyanate polyurethane prepolymer M-NIPU-2

[0034] 3) Preparation of self-healing non-isocyanate polyurethane: Weigh 8 parts of M-NIPU-1 and 12 parts of bismaleimide prepared in step 1) in molar parts, heat and mix at 160°C, pour into a mold Air bubbles were removed in a vacuum oven, and then cured at 60°C for 24 hours to obtain self-healing non-isocyanate polyurethane. Its tensile strength is 9MPa, and its ...

Embodiment 2

[0036] Take by weighing 6 parts of embodiment 1 in step 1) M-NIPU-1 and 2 parts of embodiment 1 in step 2) make M-NIPU-2 and 12 parts of bismaleimides in molar fractions , heated and mixed at 160°C, poured into a mold to remove air bubbles in a vacuum oven, and then cured at 60°C for 24 hours to obtain self-healing non-isocyanate polyurethane. Its tensile strength is 13MPa, and its initial self-healing efficiency is 71%.

Embodiment 3

[0038] Take by mole fraction 4 parts of M-NIPU-1 that step 1) makes in embodiment 1 and step 2) make M-NIPU-2 and 12 parts of bismaleimides in 4 parts of embodiment 1 , heated and mixed at 160°C, poured into a mold to remove air bubbles in a vacuum oven, and then cured at 60°C for 24 hours to obtain self-healing non-isocyanate polyurethane. Its tensile strength is 16MPa, and its initial self-healing efficiency is 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com