3D printing modified polypropylene composition and preparation method thereof

A polypropylene composition, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of narrow processing window, slow molding rate, low crystallization temperature, etc., to improve melt strength, increase crystallization temperature and crystallization rate, The effect of improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

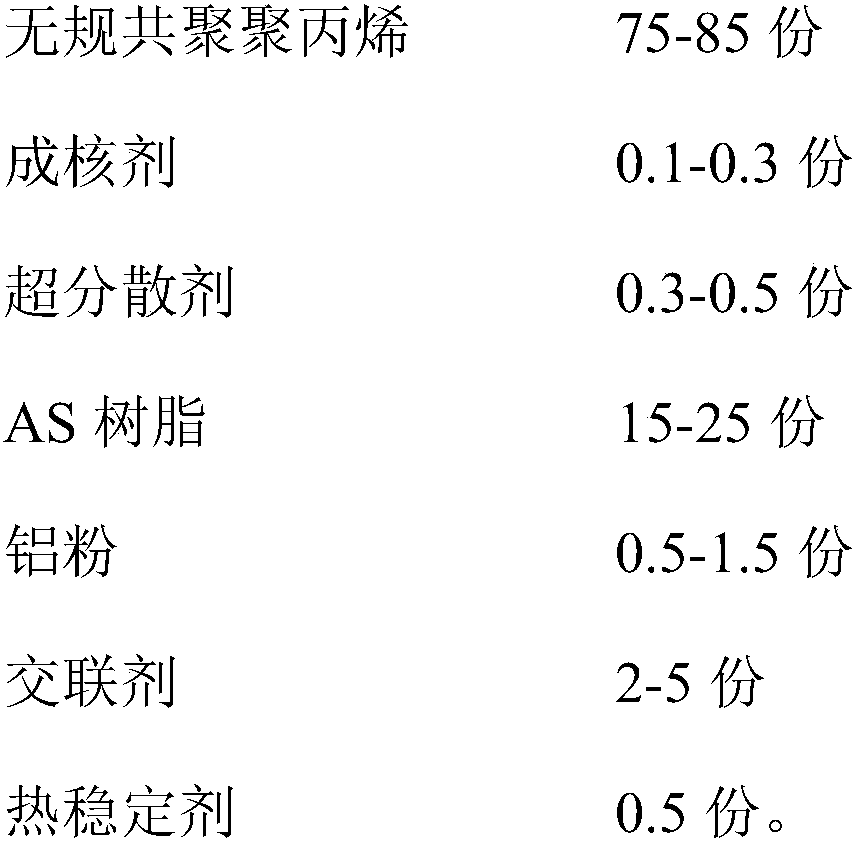

[0025] Add 75 parts of random copolymerized polypropylene, 0.1 part of nucleating agent, 0.3 part of hyperdispersant, 25 parts of AS resin, 0.5 part of aluminum powder, 2 parts of crosslinking agent, and 0.5 part of heat stabilizer into the high-speed mixer and mix at high speed After 5 minutes, the homogeneously mixed material was added into a twin-screw extruder, mixed and extruded, and cooled to obtain a 3D printing modified polypropylene composition. The extrusion temperatures of each extrusion zone in the twin-screw extruder are 170°C, 175°C, 185°C, 195°C, 205°C, 205°C, 210°C, 210°C, 215°C, 220°C respectively.

[0026] The product performance is shown in Table 1.

Embodiment 2

[0028] Add 80 parts of random copolymerized polypropylene, 0.2 parts of nucleating agent, 0.4 parts of hyperdispersant, 20 parts of AS resin, 1.0 part of aluminum powder, 3.5 parts of crosslinking agent, and 0.5 parts of heat stabilizer into the high-speed mixer and mix at high speed After 5 minutes, the homogeneously mixed material was added into a twin-screw extruder, mixed and extruded, and cooled to obtain a 3D printing modified polypropylene composition. The extrusion temperatures of each extrusion zone in the twin-screw extruder are 165°C, 170°C, 180°C, 190°C, 200°C, 200°C, 205°C, 205°C, 210°C, 215°C respectively. The product performance is shown in Table 1.

Embodiment 3

[0030] Add 85 parts of random copolymerized polypropylene, 0.3 parts of nucleating agent, 0.5 parts of hyperdispersant, 15 parts of AS resin, 1.5 parts of aluminum powder, 5 parts of crosslinking agent, and 0.5 parts of heat stabilizer into the high-speed mixer and mix at high speed After 5 minutes, the homogeneously mixed material was added into a twin-screw extruder, mixed and extruded, and cooled to obtain a 3D printing modified polypropylene composition. The extrusion temperatures of each extrusion zone in the twin-screw extruder are 160°C, 165°C, 175°C, 185°C, 195°C, 195°C, 200°C, 200°C, 205°C, 210°C respectively.

[0031] The product performance is shown in Table 1.

[0032] Table 1: Properties of 3D printing modified polypropylene compositions of Examples 1-3

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com