Intelligent accumulation and fermentation tank

A stacking fermentation and intelligent technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc., can solve production process limitations, affect the stability of the fermentation process, and cannot intervene in the fermentation process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

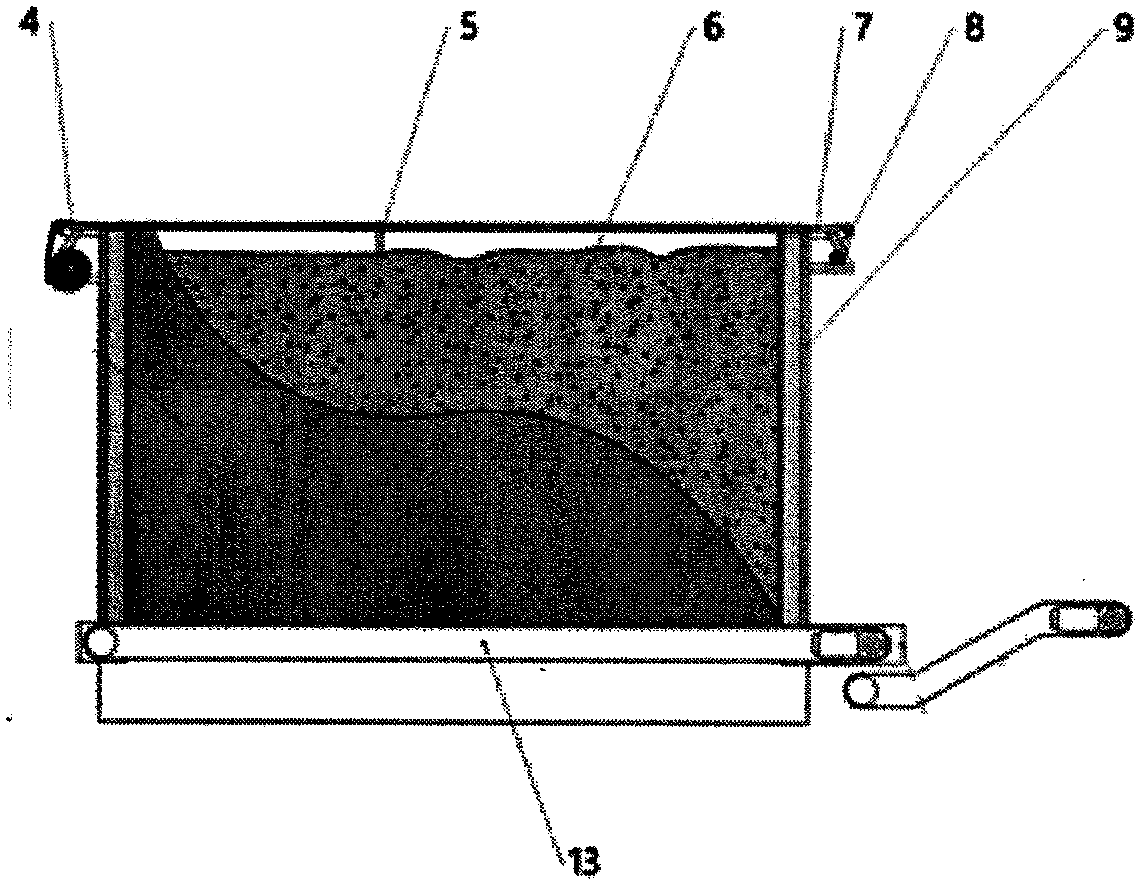

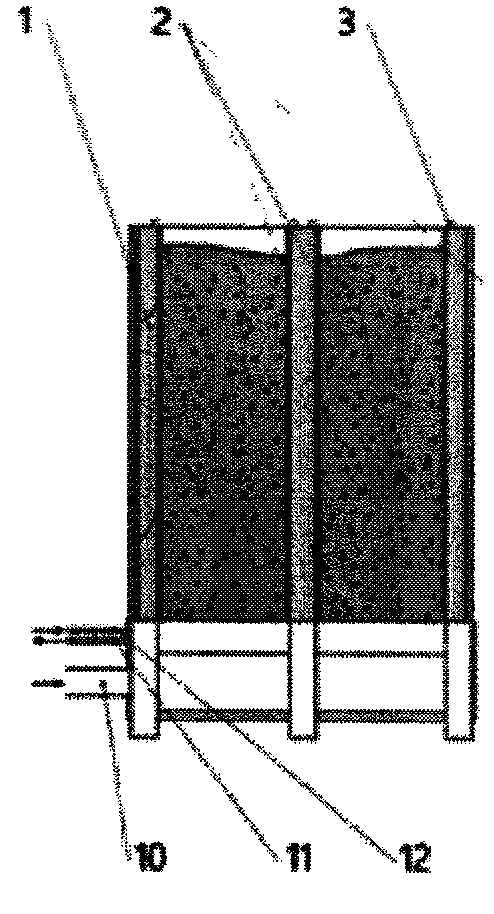

[0017] Depend on Figure 1-2 It can be seen that the present invention includes a tank body, a wall plate, a partition, a circulating water system, a ventilation pipe, a flat conveyor belt, a thermal insulation blanket roll, a motor and a cable, and the partitions are evenly and vertically arranged in the tank body, and the fermentation raw materials are located between the partitions , the wall panels and partitions are all orifice plates, the ventilation pipes are connected with the partitions, the circulating water system consists of circulating water pipes, circulating water inlets, and circulating water outlets. The outlet is connected; the cable is located on the top of the tank, and the cable is respectively connected to the sprocket and the motor. The insulation blanket roll is set on the cable, and its movement can be controlled by the zipper; the flat conveyor belt is located below the discharge port.

[0018] The end of the insulation blanket roll is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com