A kind of fermentation medium and culture method thereof for fermentative production of thiopeptide antibiotic nosiheptide

A technology of thiopeptide antibiotics and fermentation medium, which is applied in the direction of fermentation and peptides, can solve the problems of strains that have not reached the maximum production capacity, high production costs, unfavorable large-scale production, etc., and can improve the production level of bacteria , to avoid process instability, to avoid the effect of greening or decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

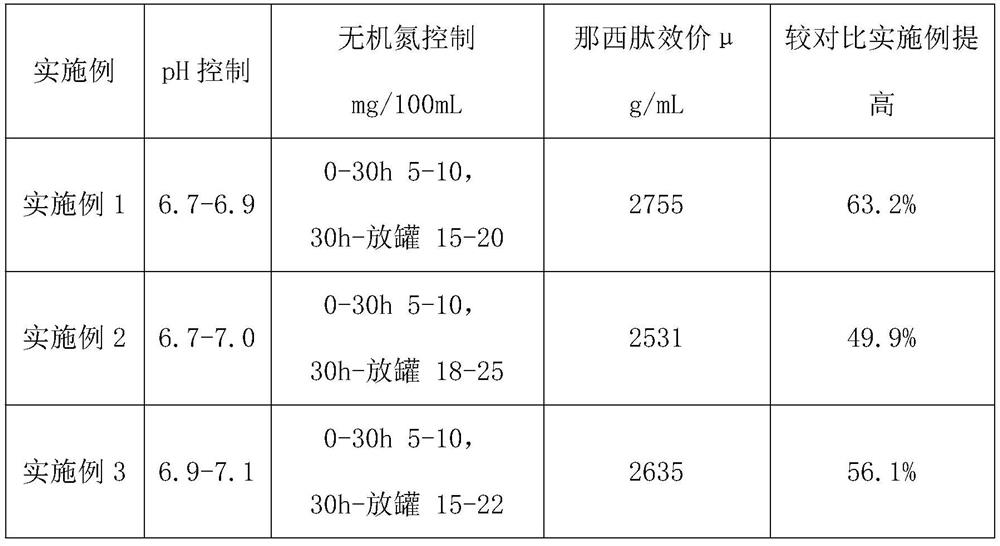

Examples

Embodiment 1

[0048] seed culture

[0049] Seed medium (g / L): glucose 20, low-temperature soybean meal 20, corn steep liquor 10, ammonium sulfate 3.0, magnesium sulfate 0.5, calcium carbonate 5.0, potassium dihydrogen phosphate 0.2, soybean oil 3.0, defoamer 0.2;

[0050] The quality requirements of the sterilized seed medium are: amino nitrogen 80-120mg / 100mL, total sugar 3.0-5.0g / 100mL, pH 6.5-7.0.

[0051] Inoculate the cultured active Streptomyces strain bottle fermentation liquid into the seed medium according to the inoculation amount of 0.2-0.3%, and cultivate it. The tank pressure is 0.04±0.05Mp, the culture temperature is 30±1℃, the ventilation ratio is 0.8-1.0vvm, and the dissolved oxygen Control it at 30-50%. When the bacterial concentration reaches above 28% and the pH value drops to 6.6-7.0, the culture time is continued for 28-32 hours.

[0052] Wherein the quality requirement of cultured active Streptomyces strain bottle fermentation liquid is: bacteria concentration 30-40%...

Embodiment 2

[0064] seed culture

[0065] Seed medium (g / L): glucose 30, low-temperature soybean meal 25, corn steep liquor 15, ammonium sulfate 4.0, magnesium sulfate 0.8, calcium carbonate 8.0, potassium dihydrogen phosphate 0.5, soybean oil 5.0, defoamer 0.3;

[0066] The quality requirements of the sterilized seed medium are: amino nitrogen 80-120mg / 100mL, total sugar 3.0-5.0g / 100mL, pH 6.5-7.0.

[0067] Inoculate the cultured active Streptomyces strain bottle fermentation liquid into the seed medium according to the inoculation amount of 0.2-0.3%, and cultivate it. The tank pressure is 0.04±0.05Mp, the culture temperature is 30±1℃, the ventilation ratio is 0.8-1.0vvm, and the dissolved oxygen Control it at 30-50%. When the bacterial concentration reaches above 28% and the pH value drops to 6.6-7.0, the culture time is continued for 28-32 hours.

[0068] Wherein the quality requirement of cultured active Streptomyces strain bottle fermentation liquid is: bacteria concentration 30-40%...

Embodiment 3

[0080] seed culture

[0081] Seed medium (g / L): glucose 40, low-temperature soybean meal powder 30, corn steep liquor 20, ammonium sulfate 5.0, magnesium sulfate 1.0, calcium carbonate 10, potassium dihydrogen phosphate 0.8, soybean oil 8.0, defoamer 0.5;

[0082] The quality requirements of the sterilized seed medium are: amino nitrogen 80-120mg / 100mL, total sugar 3.0-5.0g / 100mL, pH 6.5-7.0.

[0083] Inoculate the cultured active Streptomyces strain bottle fermentation liquid into the seed medium according to the inoculation amount of 0.2-0.3%, and cultivate it. The tank pressure is 0.04±0.05Mp, the culture temperature is 30±1℃, the ventilation ratio is 0.8-1.0vvm, and the dissolved oxygen Control it at 30-50%. When the bacterial concentration reaches above 28% and the pH value drops to 6.6-7.0, the culture time is continued for 28-32 hours.

[0084] Wherein the quality requirement of cultured active Streptomyces strain bottle fermentation liquid is: bacteria concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com