Fence vertical column base with locking function

A column and fence technology, applied in the direction of fences, building types, buildings, etc., can solve the problems of cumbersome installation and disassembly, difficult to fix the fence, poor wind resistance, etc., and achieve the effect of convenient disassembly and operation, stable and reliable support, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

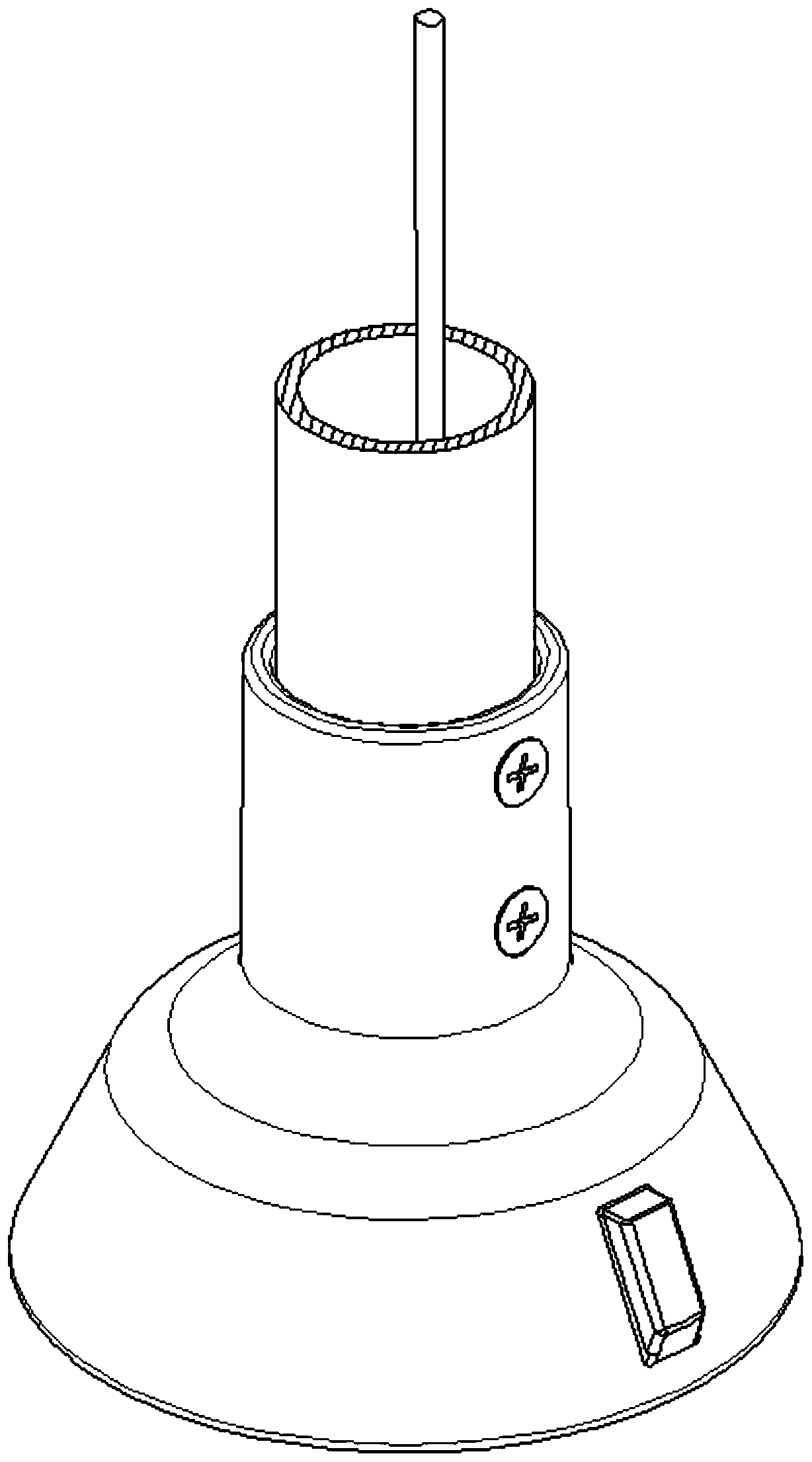

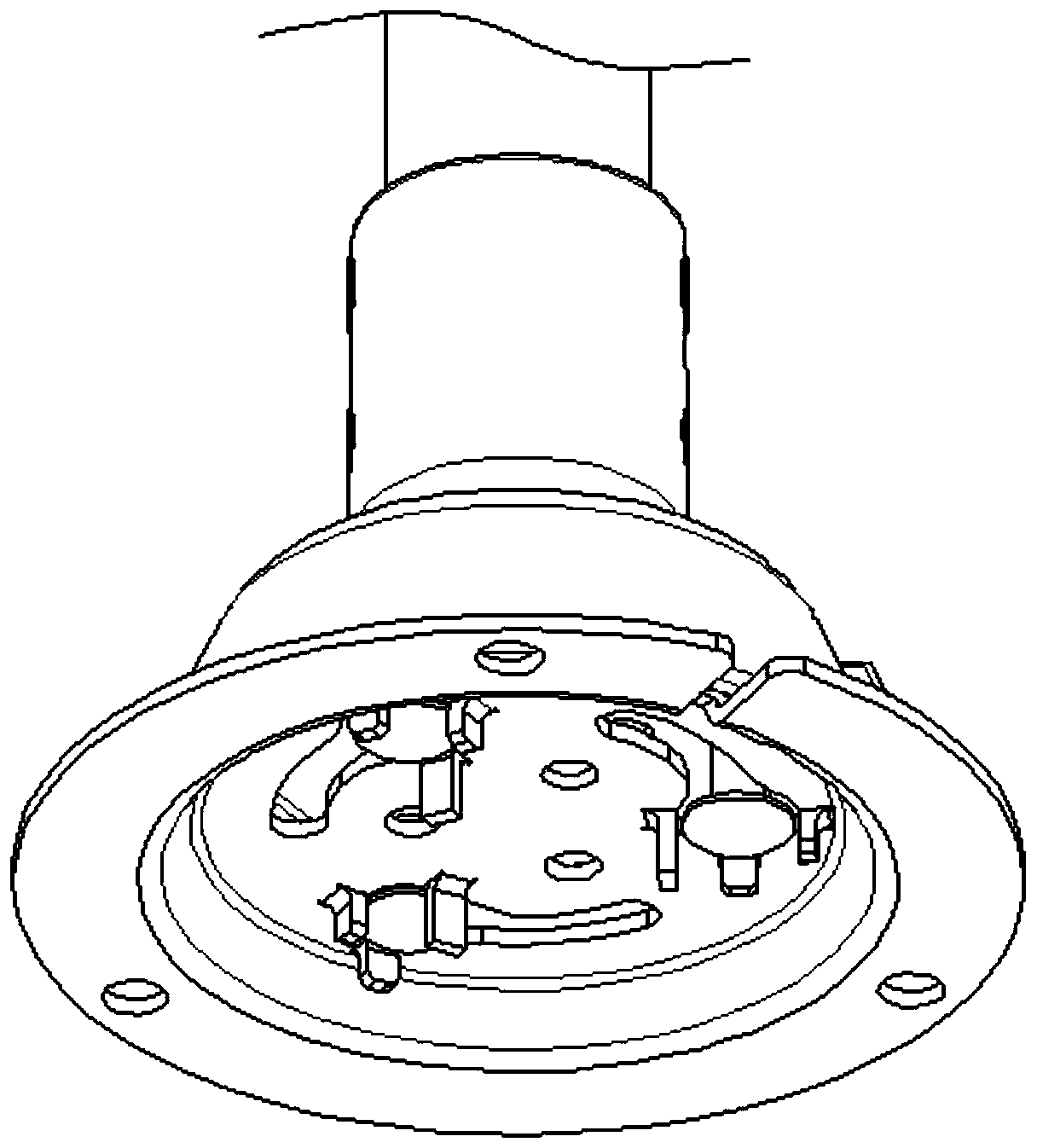

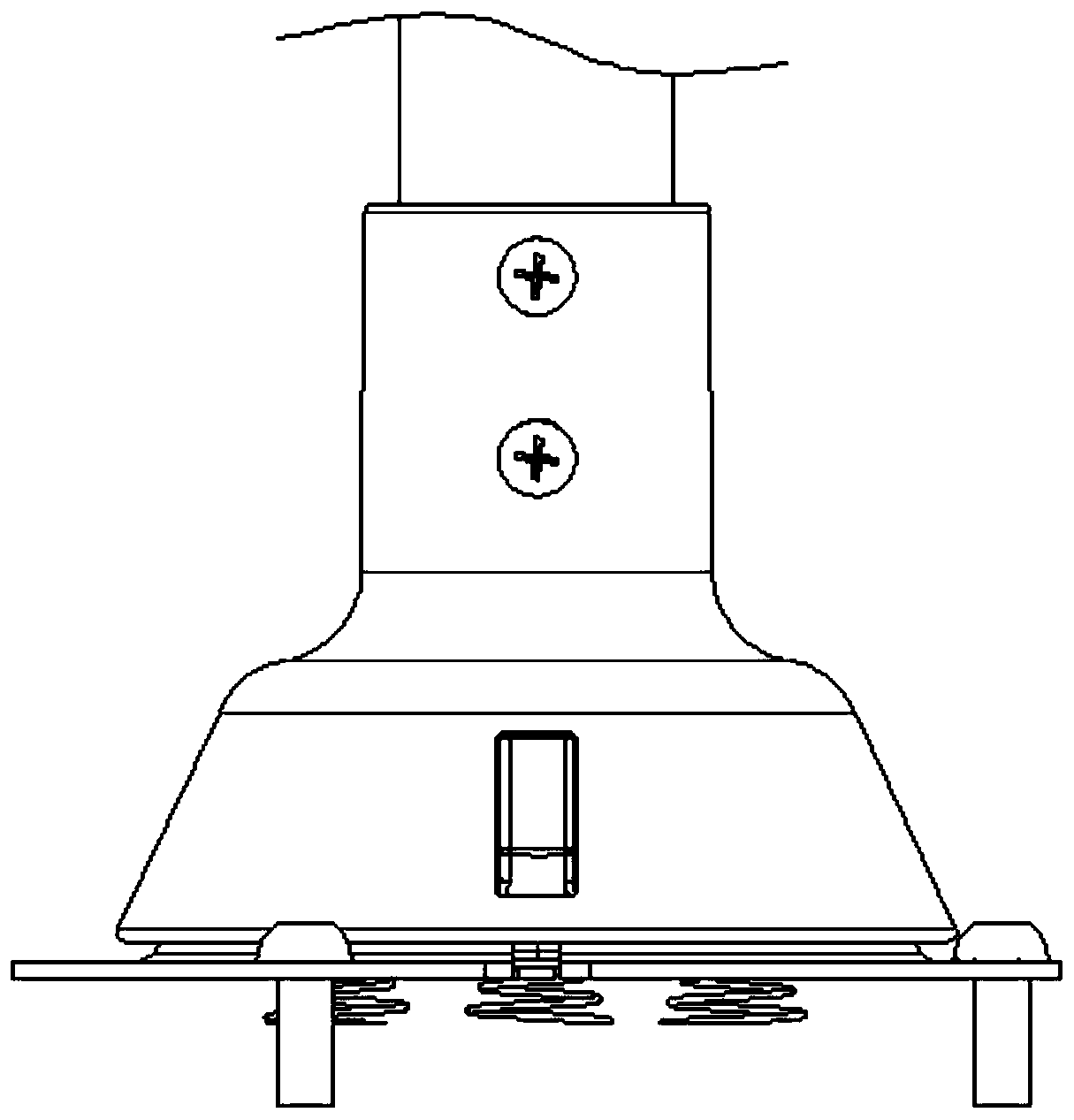

[0027] As shown in the figure, a fence post base with a locking function is fixedly installed on the ground at the electrical equipment repair and maintenance work site. Externally, the safety fence column 1 is installed and supported through the card cover and the card seat; multiple card seats are set along the electrical equipment maintenance work site to fully set up the safety fence, and the safety fence is installed and supported by multiple safety fence columns to adapt to In the field environment, each card holder can be connected with the card cover at the bottom of any safety fence column, and the card cover at the bottom of each safety fence column can also be connected with any card seat on the site ground, which is easy to operate.

[0028] In the specific structure, the middle part of the card holder B3 protrudes upwards to form a tapered card platform structure, and the edge extends downwards to form a flange ring structure. Three bolt connection holes are evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com