Sea area high-water-pressure shield method tunnel emergency tool change structure and construction method

A technology of high water pressure and shield method, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of small impact on sea surface, low construction risk, and inability to apply submarine tunnels, etc., to achieve low construction risk and good waterproof effect , Tool change and repair are safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

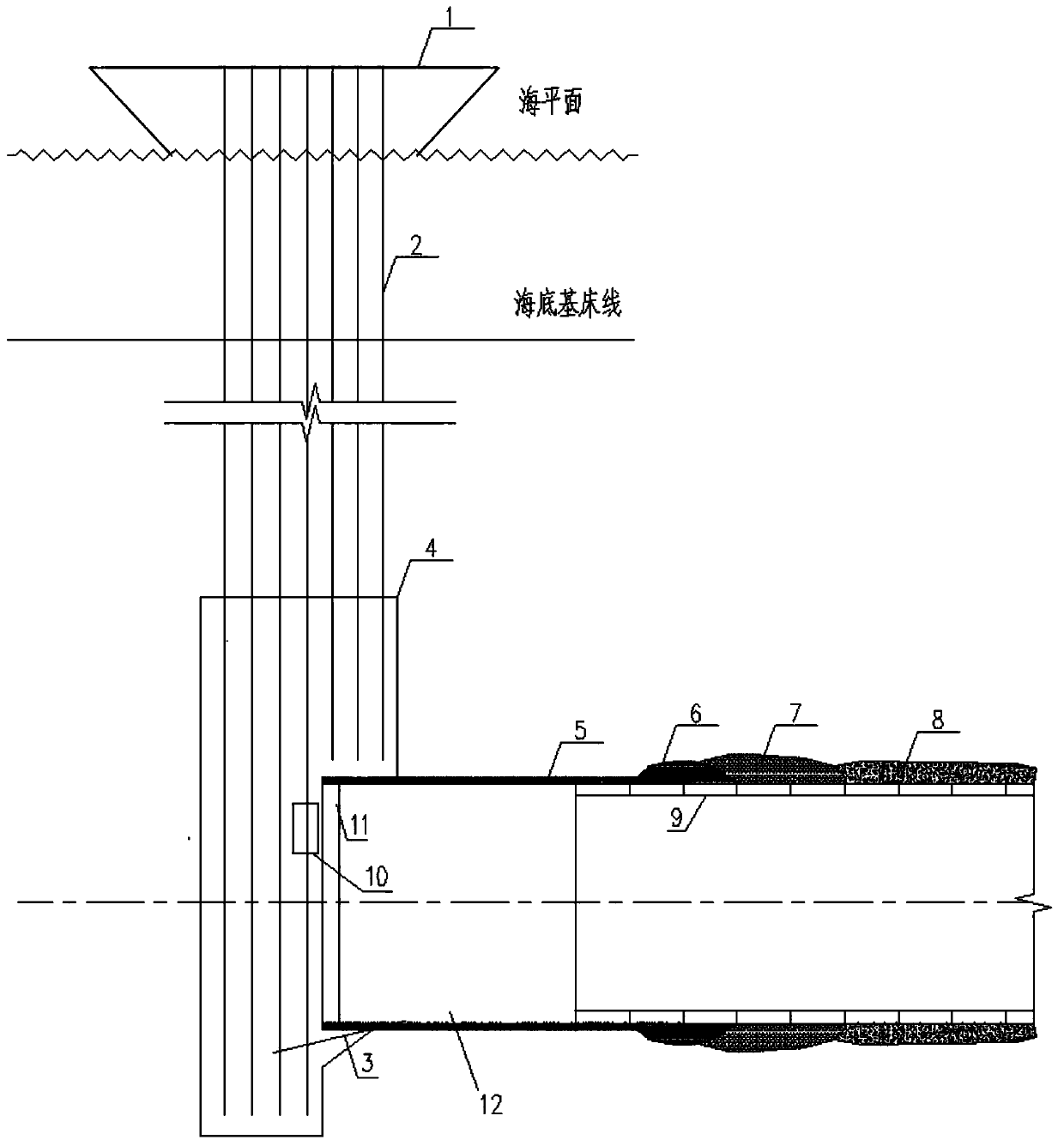

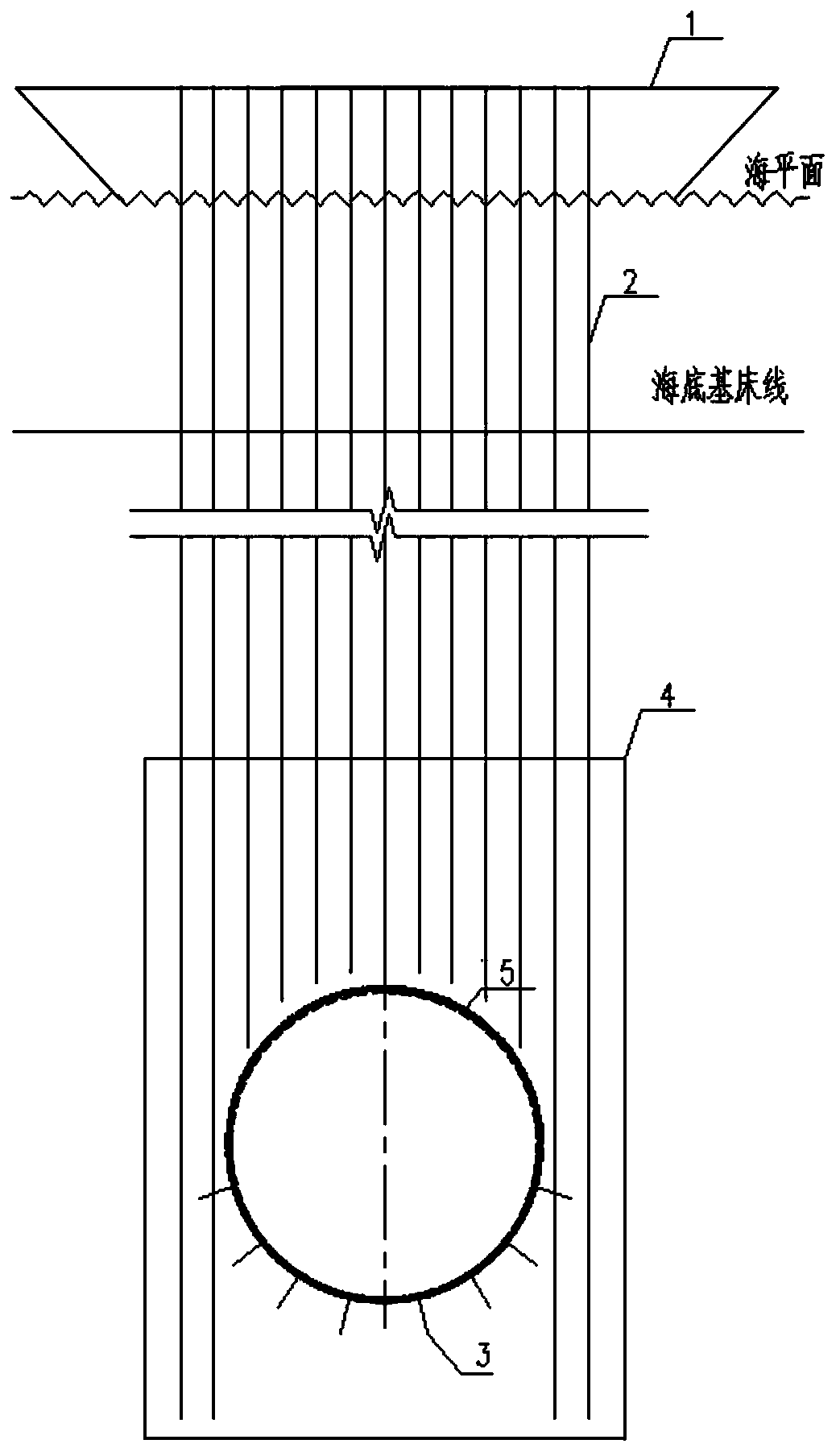

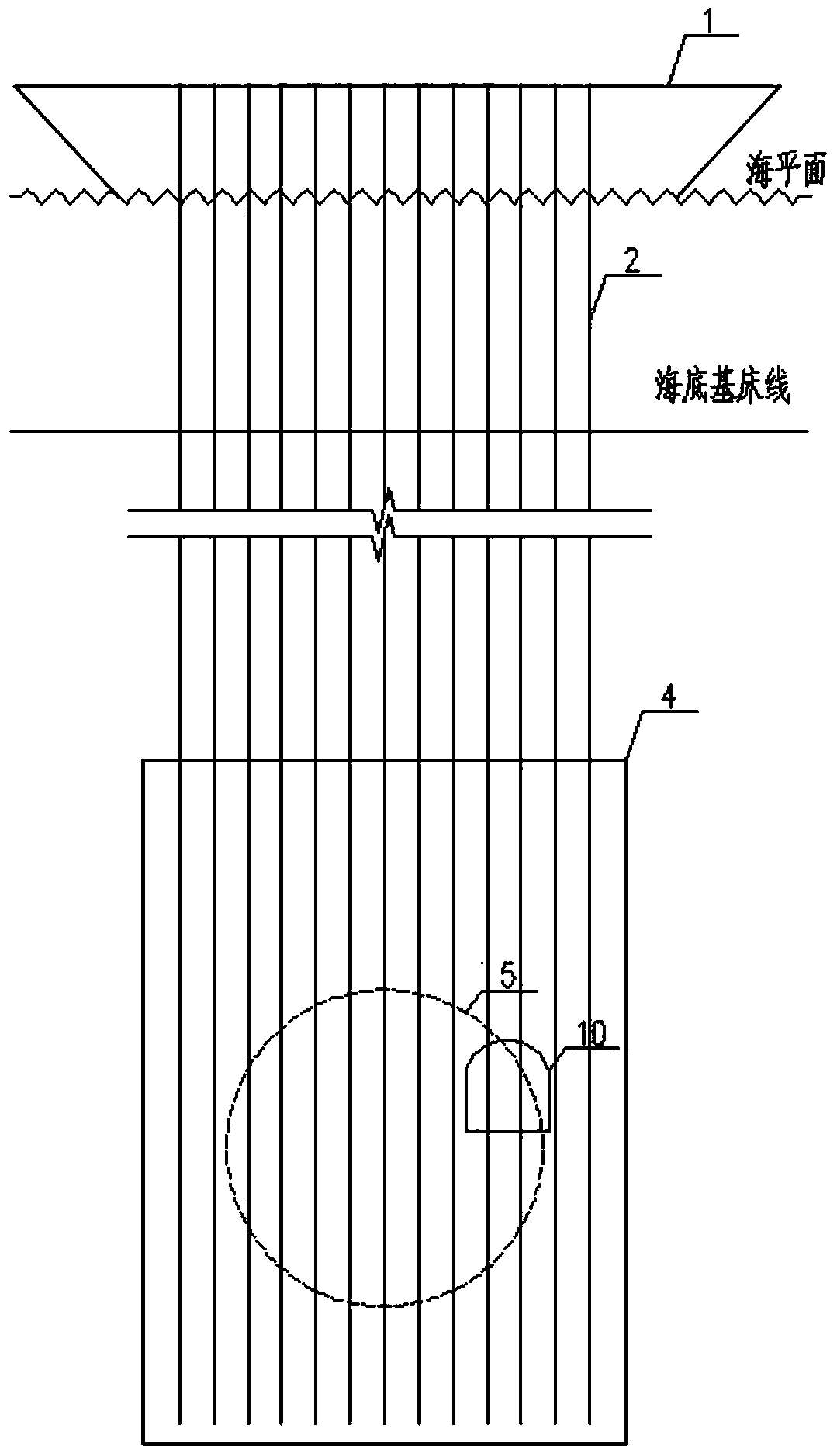

[0044] The embodiment of the present invention discloses an emergency tool change structure for a sea area high water pressure shield tunnel, which includes a shield machine 12, a freezing operation platform 1, a soil freezing curtain 4, and a shield protection structure 5;

[0045]A shield machine 12 is provided below the frozen operation platform 1, and the frozen operation platform 1 and the shield machine 12 are connected by a soil freezing curtain 4; the soil freezing curtain 4 is composed of a vertical freezing structure 2 at the front end and a vertical freezing structure 3 at the bottom ;

[0046] The end of the shield machine 12 facing the soil freezing curtain 4 is provided with a cutter head 11, the side surface of one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com