Longitudinal beam driving structure for grate cooler material conveying

A driving structure and grate cooler technology, which is applied in the direction of processing discharged materials, mechanical equipment, fluid pressure actuators, etc., can solve the problems of high maintenance frequency, heavy hydraulic cylinder load, inconvenient installation and disassembly, etc., and achieve volume And the effect of small weight, small running resistance and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

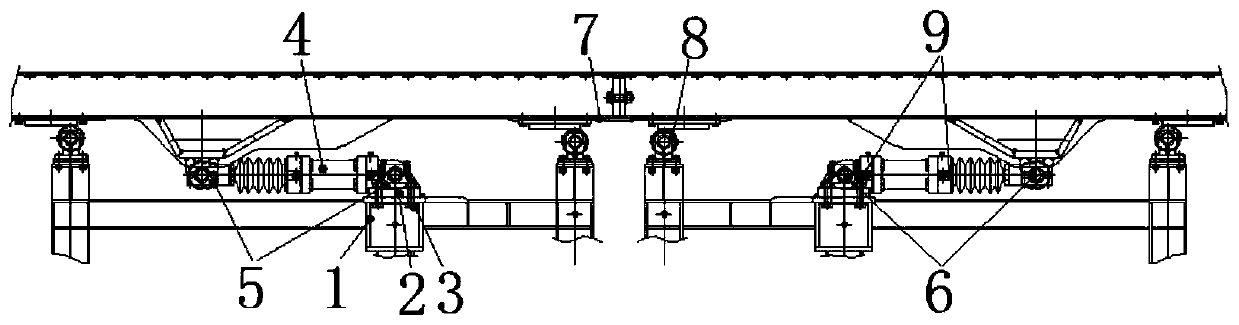

[0021] Such as figure 1 As shown, the longitudinal beam drive structure used for grate cooler material delivery includes a crossbeam 1 and a drive beam 7 arranged longitudinally above the crossbeam. The crossbeam 1 is provided with support wheels 8 for supporting the drive beam and for traction driving. The hydraulic drive structure of the beam movement, the hydraulic drive structure includes two driving hydraulic cylinders 4 or more than two driving hydraulic cylinders, each row of driving beams is driven by at least two driving hydraulic cylinders, and each driving hydraulic cylinder is set on the beam through a fixed base 1 on.

[0022] The support wheels 8 are arranged in two or more groups vertically; the support wheels are arranged in two or more groups horizontally to support two or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com