Double-coated diaphragm applied to lithium-selenium disulfide battery and preparation method and application thereof

A technology of selenium disulfide and battery separator, used in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problem of low surface loading of active materials, achieve excellent reversible performance, excellent electrochemical performance, protection effect of avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for a double-coated diaphragm applied to a lithium-selenium disulfide battery:

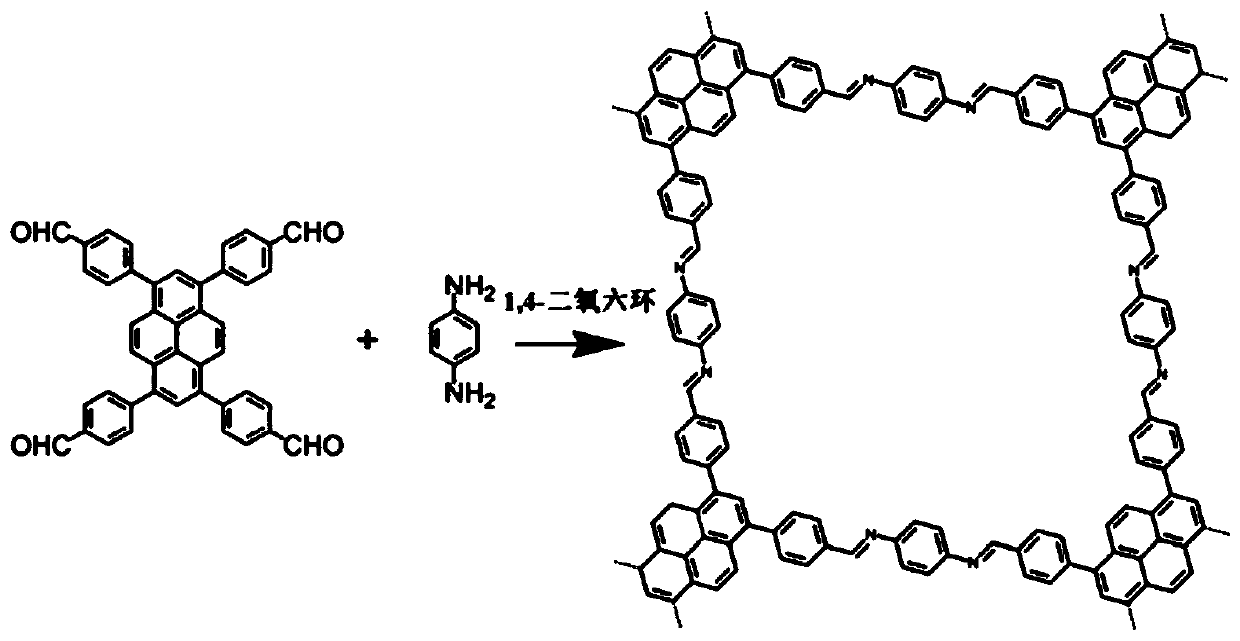

[0035] 1) Preparation of raw materials for slurry A: Take 1,3,6,8-tetrakis(4-formylphenyl)perylene and p-phenylenediamine at a molar ratio of 1:2, add 4mL of 1,4-di Oxycycline, then add 3mol / L acetic acid solution, the addition amount is 5% of the total volume of the above organic solvent, then pass through argon and seal it, put the above mixed solution in an oven at 120°C for 72h, and then use 1,4-dioxane, tetrahydrofuran and acetone are washed to obtain yellow powder PA-COF, which is the raw material of coating A;

[0036]2) Preparation of slurry A: Mix PA-COF and LA132 water-based binder prepared in step 1) at a ratio of 5:1, then add 2 mL of n-propanol aqueous solution dropwise, and mix well to obtain slurry A ;

[0037] 3) Preparation of slurry B: take industrial grade TiO 2 powder according to TiO 2 1. Conductive carbon black and water-based binder are fully ...

Embodiment 2

[0040] A preparation method for a double-coated diaphragm applied to a lithium-selenium disulfide battery:

[0041] 1) Preparation of raw materials for slurry A: Take 1,3,6,8-tetrakis(4-formylphenyl)perylene and p-phenylenediamine at a molar ratio of 1:2, add 4mL of 1,4-di Oxycycline, then add 3mol / L acetic acid solution, the addition amount is 5% of the total volume of the above organic solvent, then pass through argon and seal it, put the above mixed solution in an oven at 120°C for 72h, and then use 1,4-dioxane, tetrahydrofuran and acetone are washed to obtain yellow powder PA-COF, which is the raw material of coating A;

[0042] 2) Preparation of slurry A: Mix PA-COF and LA132 water-based binder prepared in step 1) at a ratio of 5:1, then add 2 mL of n-propanol aqueous solution dropwise, and mix well to obtain slurry A ;

[0043] 3) Preparation of slurry B: take industrial grade TiO 2 powder according to TiO 2 1. Conductive carbon black and water-based binder are fully...

Embodiment 3

[0046] A preparation method for a double-coated diaphragm applied to a lithium-selenium disulfide battery:

[0047] 1) Preparation of raw materials for slurry A: Take 1,3,6,8-tetrakis(4-formylphenyl)perylene and p-phenylenediamine at a molar ratio of 1:2, add 4mL of 1,4-di Oxycycline, then add 3mol / L acetic acid solution, the amount added is 50% of the total volume of the above organic solvent, then pass through argon and seal it, put the above mixed solution in an oven at 120°C for 72h, and then use 1,4-dioxane, tetrahydrofuran and acetone are washed to obtain yellow powder PA-COF, which is the raw material of coating A;

[0048] 2) Preparation of slurry A: Mix the PA-COF and LA132 water-based binder prepared in step 1) in a ratio of 3:1, then add 2 mL of n-propanol aqueous solution dropwise, and mix well to obtain slurry A ;

[0049] 3) Preparation of slurry B: take industrial grade TiO 2 powder according to TiO 2 1. Conductive carbon black and water-based binder are ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com