Composition, kit and method for coloring keratinous fibers

A film-forming, prepolymer technology, used in fiber processing, pharmaceutical formulations, textiles and papermaking, etc., can solve problems such as carcinogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

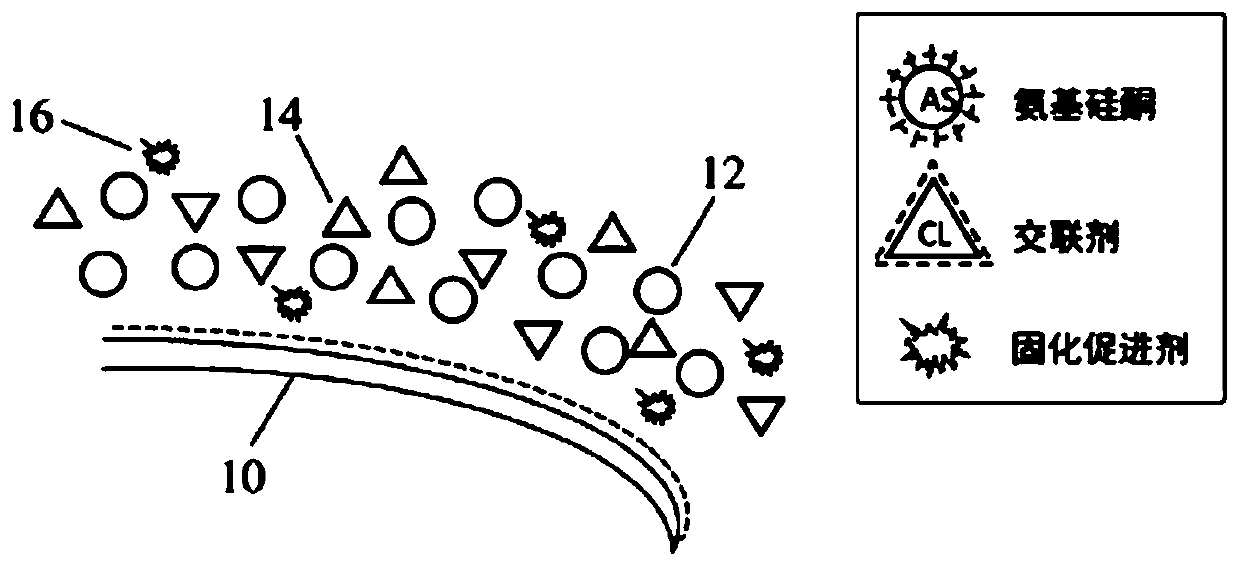

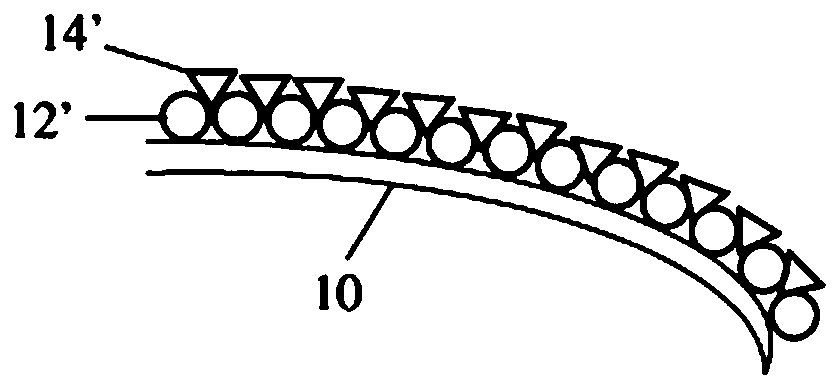

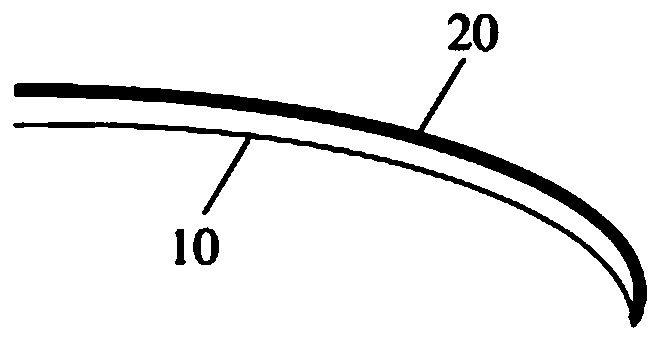

Method used

Image

Examples

Embodiment 1

[0454] Example 1: Dyeing of light-colored keratin fibers

[0455] Material

[0456] the hair

[0457] Yak white body hair; Chinese black human hair; European black human hair (all supplied by Kerling International Haarfabrik GmbH as bundles of approximately 2.5 g of hair approximately 7 cm long)

[0458] organic pigment

[0459] Green K8730 (BASF, Germany)

[0460] Yellow 3RT (BASF, Germany)

[0461] Magenta 2012 (BASF, Germany)

[0462] Dispersant

[0463] 2-Ethylhexanoic acid (Sigma-Aldrich, USA)

[0464] Reactive Condensation Curable Amino Silicone Prepolymers

[0465] Amino silicone ATM 1322 (amine value 80); ( Inc., USA)

[0466] Amino silicone GP-34 (amine value 3.3, MW ~ 33,596); amino silicone GP-145 (amine value 11, MW ~ 18,052); amino silicone GP-397 (amine value 116, MW ~ 3,754); amino silicone Ketone GP-657 (amine value 54, MW ~ 3,700); and amino silicone GP-846 (amine value 110); (all supplied by Genesee Polymers Corp., USA).

[0467] Amino s...

Embodiment 2

[0526] Example 2: Composition for dyeing keratin fibers

[0527] Preparation of the composition

[0528] Samples AA to AN were prepared comprising the components as detailed in Table 2 and as described below, wherein the condensation curable silicone was selected from the list shown in the table below, where some information about these elastomers is given parameter.

[0529]

[0530]

[0531] *Amine value refers to the number of milliliters of 0.1N HCl required to neutralize 10g of polymer

[0532] **LP = linear polymer; BF = branched polymer

[0533] Table 2

[0534] All compositions of Table 2 were prepared as follows:

[0535] 8 g of reactive aminosilicone were added to 2 g of milled slurry, wherein the slurry contained Subgranules of Yellow 3RT and BYK LPX 21879 used as dispersant were prepared as described above; Mix on surface. The mixture was then homogenized using an IKA Ultra Turrax T25 at 25,000 rpm for 30 seconds to obtain a dye paste. Containing ...

Embodiment 3

[0551] Example 3: Emulsions containing crosslinkers for dyeing keratin fibers

[0552] Material

[0553]

[0554]

[0555] Preparation of the composition

[0556] Samples BA to BE were prepared as described below. All compositions have a pH of about 10 unless otherwise stated.

[0557] Sample BA: 8 g of reactive aminosilicone prepolymer (GP-397) was mixed with 8 g of reactive aminosilicone monomer ( SIVO 210, which itself contains a mixture of three condensation curable amino silicone monomers) mixed. This mixture was added to 2 g of the milled slurry prepared as described above, which slurry contained Submicron particles of Yellow 3RT with BYK LPX 21879 (at a 1:1 w / w ratio); Mix on surface. The mixture was then homogenized using an IKA Ultra Turrax T25 at 25,000 rpm for 30 seconds to obtain a dye paste. 0.18 g of the dye paste was diluted with 60 g of water. The diluted mixture was then sonicated using a Qsonica Sonicator Q700 at 80% amplitude for 10 seconds ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com