Ditching and reshaping integrated machine for new agriculture

An all-in-one machine and agricultural technology, applied in agricultural machinery and tools, agriculture, application, etc., can solve problems such as large limitations, inability to shape furrows and ridges, and insufficient soil tightness, so as to achieve a high degree of integration, avoid stuck machinery, Functional full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

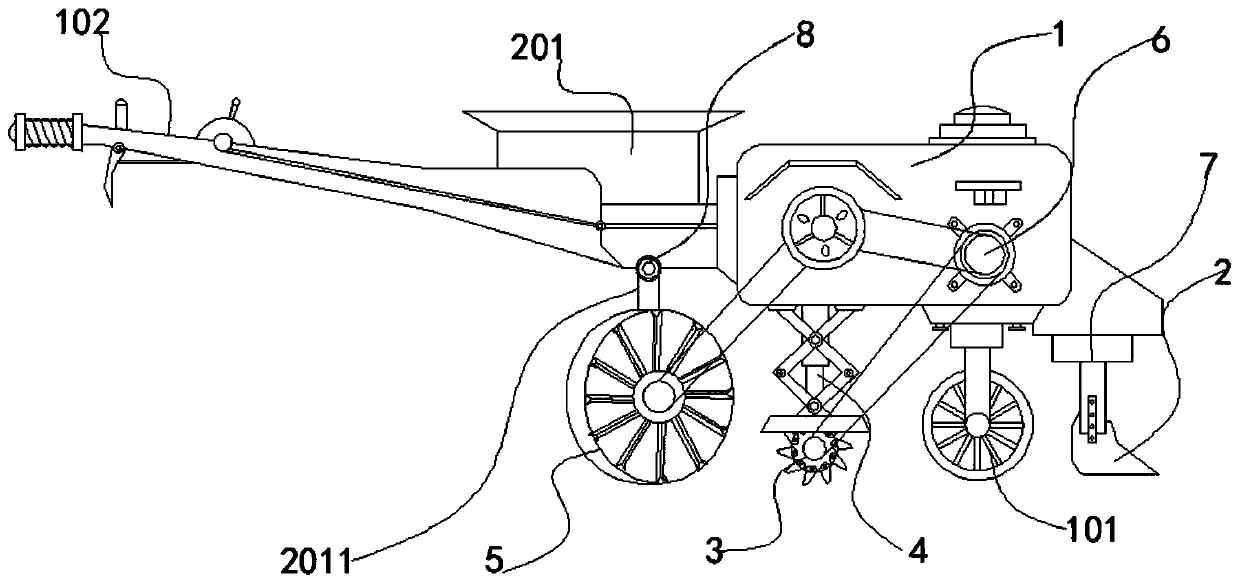

[0030] as attached figure 1 to attach Figure 6 Shown:

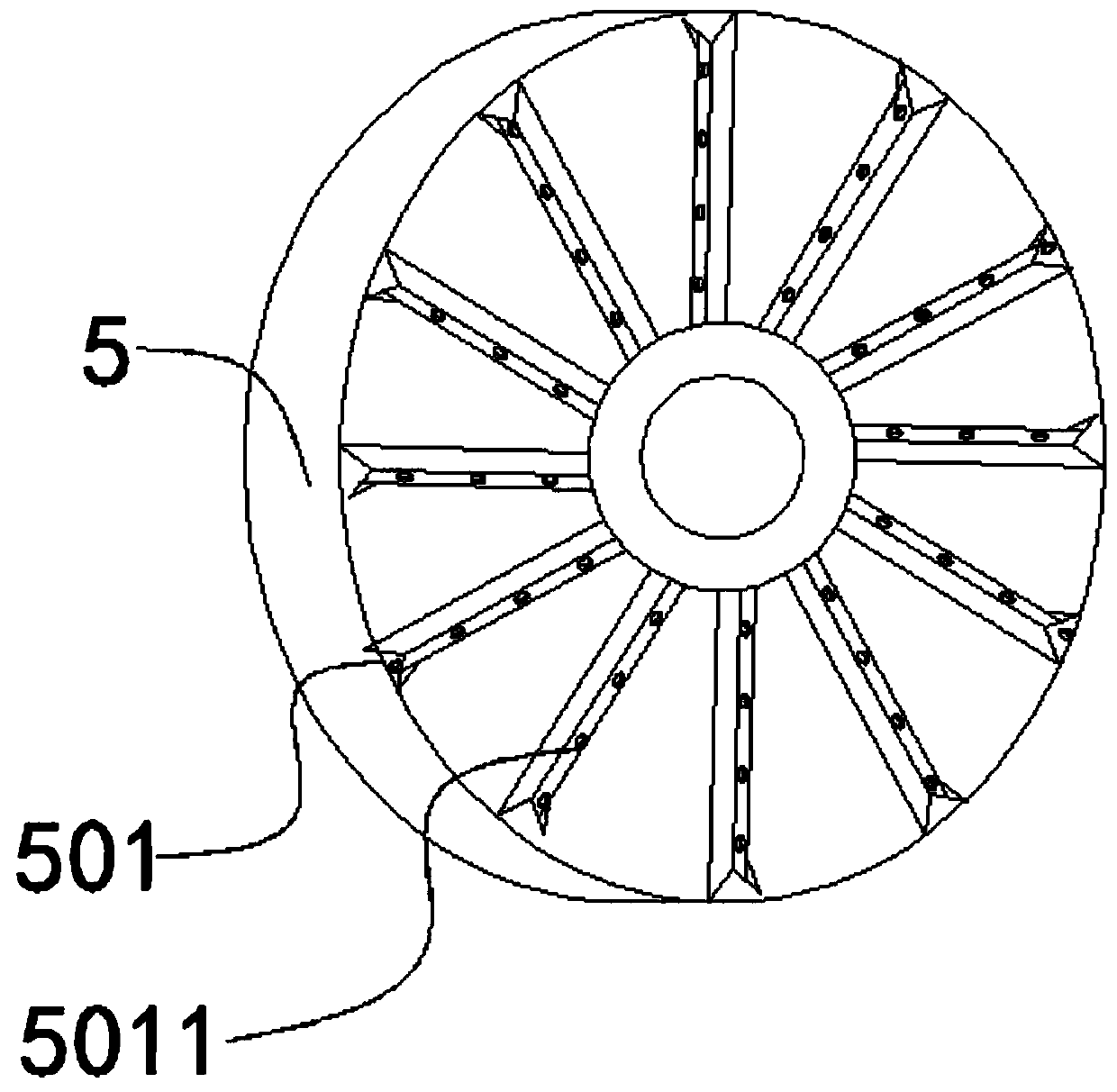

[0031] The present invention provides a new integrated ditching and shaping machine for agriculture. In the new agricultural ditching and shaping integrated machine, a diesel engine 1 and an adjustment frame 7 are fixedly connected to the upper side of the hand-held frame 102 in turn, and a diesel engine 1 and an adjustment frame 7 are fixedly connected to the bottom of the adjustment frame 7. The double-sided plow share 2 is fixedly connected with a material trough 201 above the middle part of the hand-held frame 102, and the bottom of the hand-held frame 102 is sequentially connected with a soil feeding mechanism and a shaping mechanism, and the bottom of the diesel engine 1 is connected with a driving wheel 101.

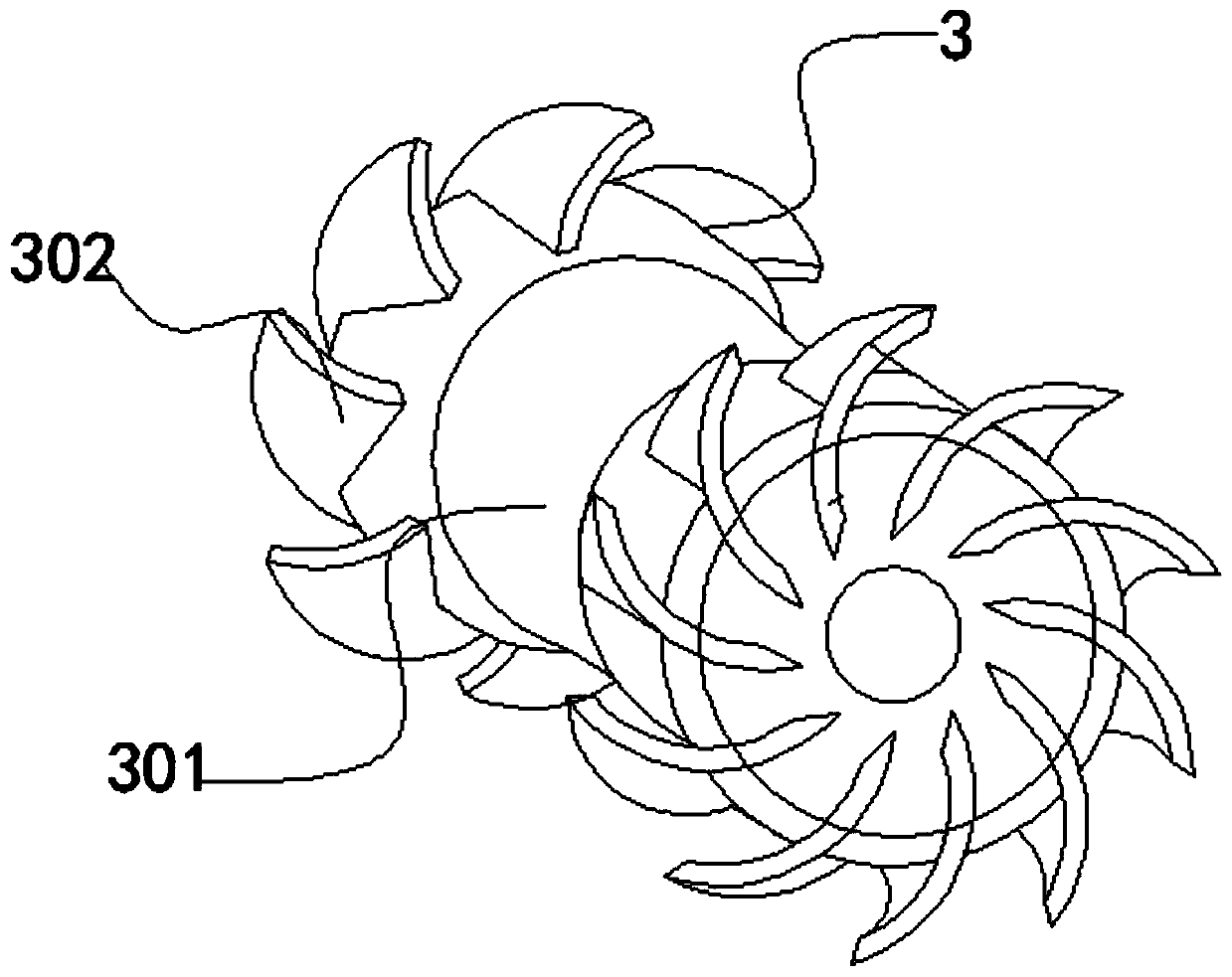

[0032] as attached figure 1 , 2 As shown: wherein, the soil feeding mechanism includes a rotary roller 3, a telescopic support frame 4, a concave surface 301, and a soil turning tooth 302. tooth 302, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com