Die forging piston double-surface drilling fixture and double-surface drilling process thereof

A drilling fixture and piston technology, applied in drilling/drilling equipment, pistons, boring/drilling and other directions, can solve the problems of low efficiency and poor precision of double-sided drilling of die forging pistons, and shorten the processing time. time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

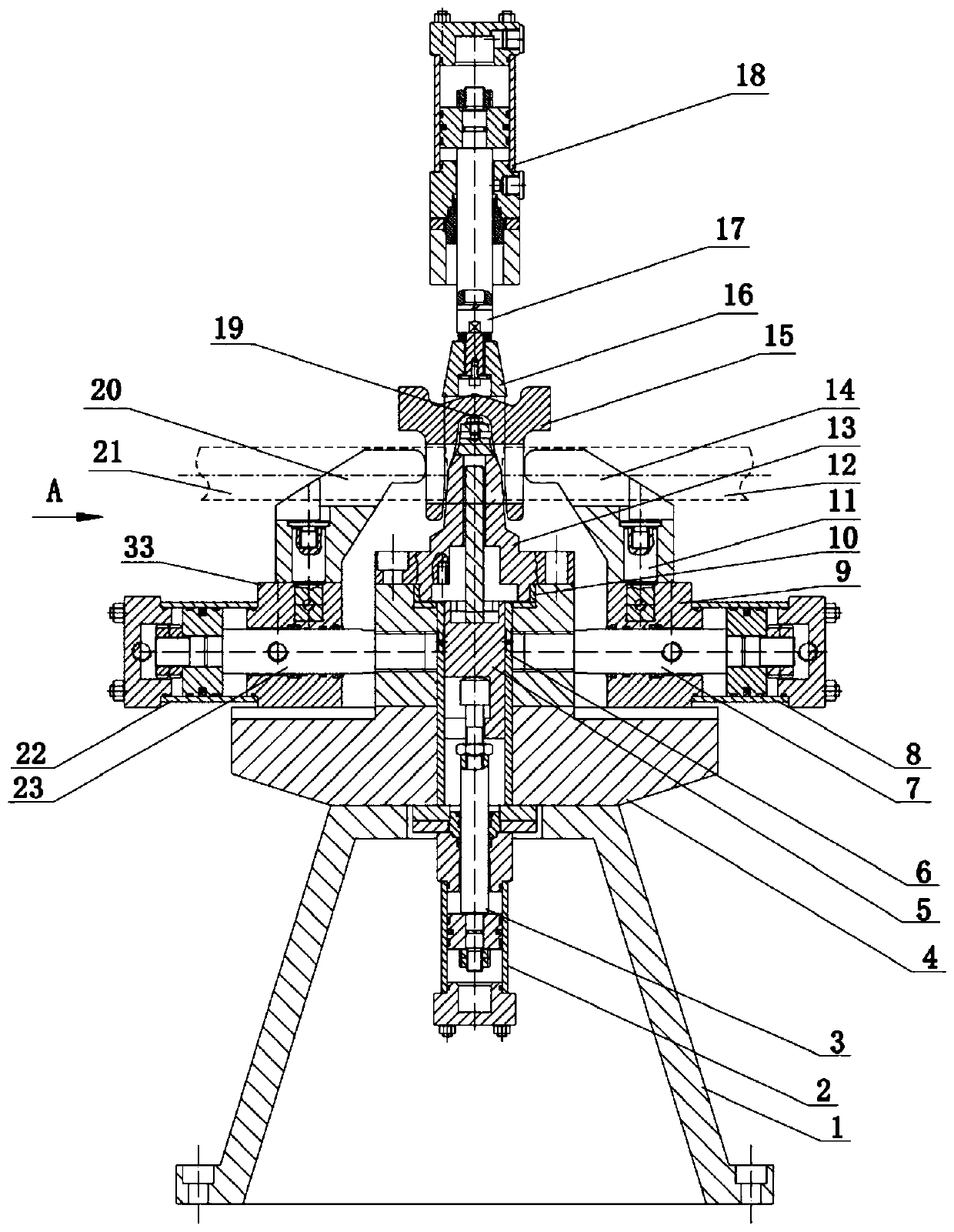

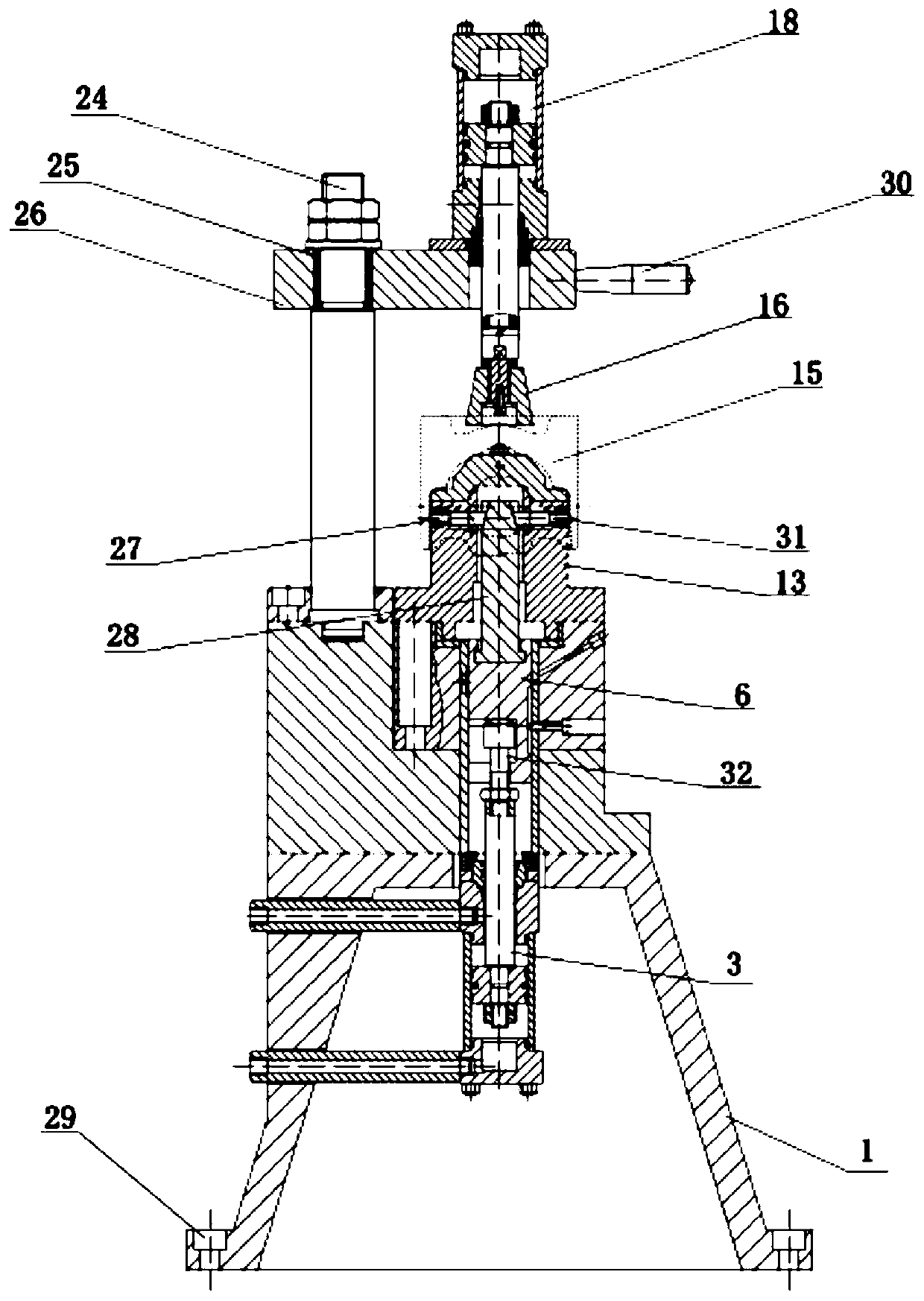

[0032] Such as figure 1 and figure 2 As shown, a die forging piston double-sided drilling fixture according to the present invention includes a die forging piston 15, a clamp base assembly, a left pressure block assembly, a right pressure block assembly, an upper pressing assembly and a lower jacking assembly, and the clamp The base assembly is used to provide an installation platform for related components, the upper pressing assembly is used to press and fix the die forging piston 15 downward from above, and the lower jacking assembly is used to form an inner cavity of the die forging piston 15 from below. The outer top expansion is fixed. The left pressing block assembly and the right pressing block assembly are used to press an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com