Scraping device for conveying of emulsion explosives

An emulsion explosive and scraping technology, which is applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problem that the conveyor belt cannot achieve flexible, accurate and reliable adjustment, affects the stability of the rubber plate body and assembly accuracy, and scrapes To solve problems such as short service life of the mechanism, achieve the effect of improving reliability and practicability, reducing the difficulty of assembly technology, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

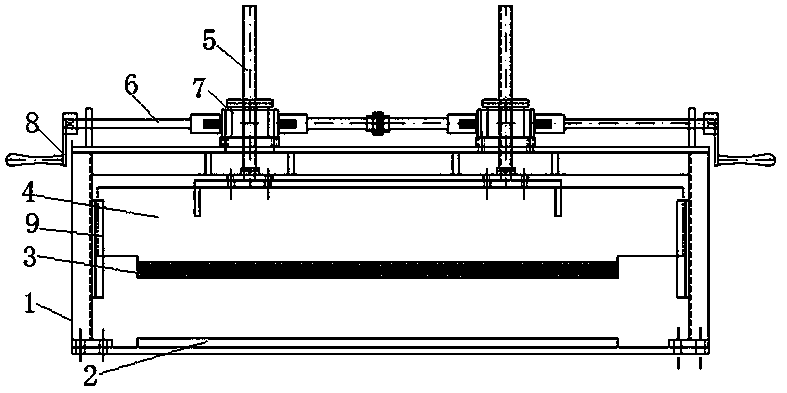

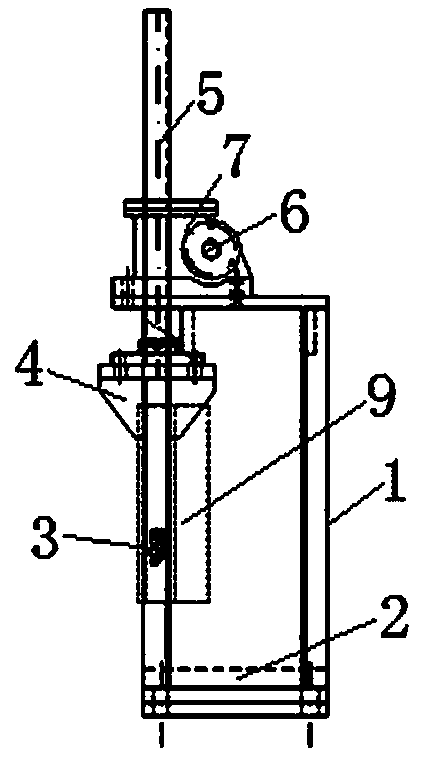

[0022] see figure 1 and figure 2 As shown, the present invention includes a belt conveyor, which is mainly composed of a frame 1, idlers and a conveyor belt 2 arranged on the idlers. The frame 1 of the belt conveyor is provided with a scraping mechanism above the conveyor belt 2 .

[0023] Specifically, the scraping mechanism is mainly composed of a rubber sheet frame 4 and a rubber sheet body 3 .

[0024] Wherein, the rubber sheet frame 4 is made of stainless steel and is a plate-shaped structure. The width of the rubber sheet frame 4 in the left and right direction is greater than the width of the conveyor belt 2 of the belt conveyor in the left and right direction. The bottom surface of the rubber sheet holder 4 is provided with a wedge-shaped groove structure with a wide bottom and a narrow mouth along the length direction—that is, the left and right directions. The rubber sheet holder 4 is assembled with the rubber sheet body 3 through the groove. Near the top left an...

Embodiment 2

[0029] The other content of this embodiment is the same as that of Embodiment 1, except that the power input part on the adjusting screw is a gear or a pulley, which is connected to the output end of the reducer through a corresponding transmission chain, and the input end of the reducer A drive motor is then connected.

Embodiment 3

[0031] The other contents of this embodiment are the same as those of Embodiment 1, except that there are three or four lifting screw rods on the rubber sheet frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com