A rice vacuum packing machine with precise metering

A vacuum packaging machine, rice technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of large rice weight gap, complex structure, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

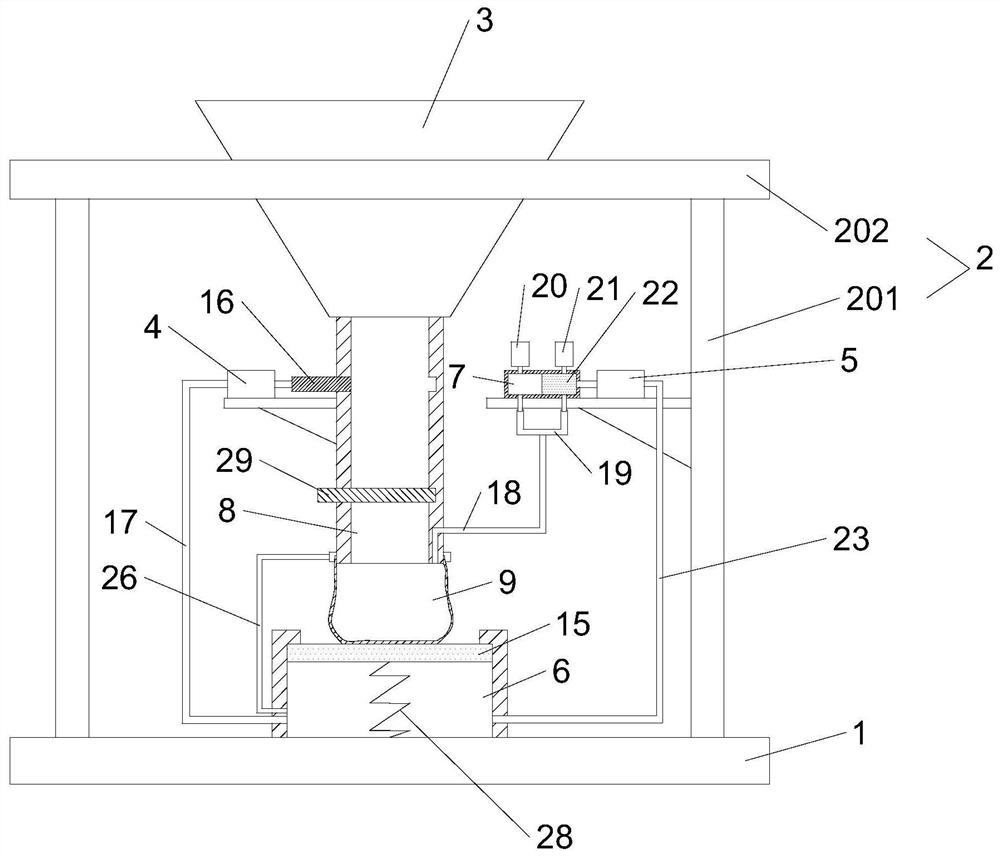

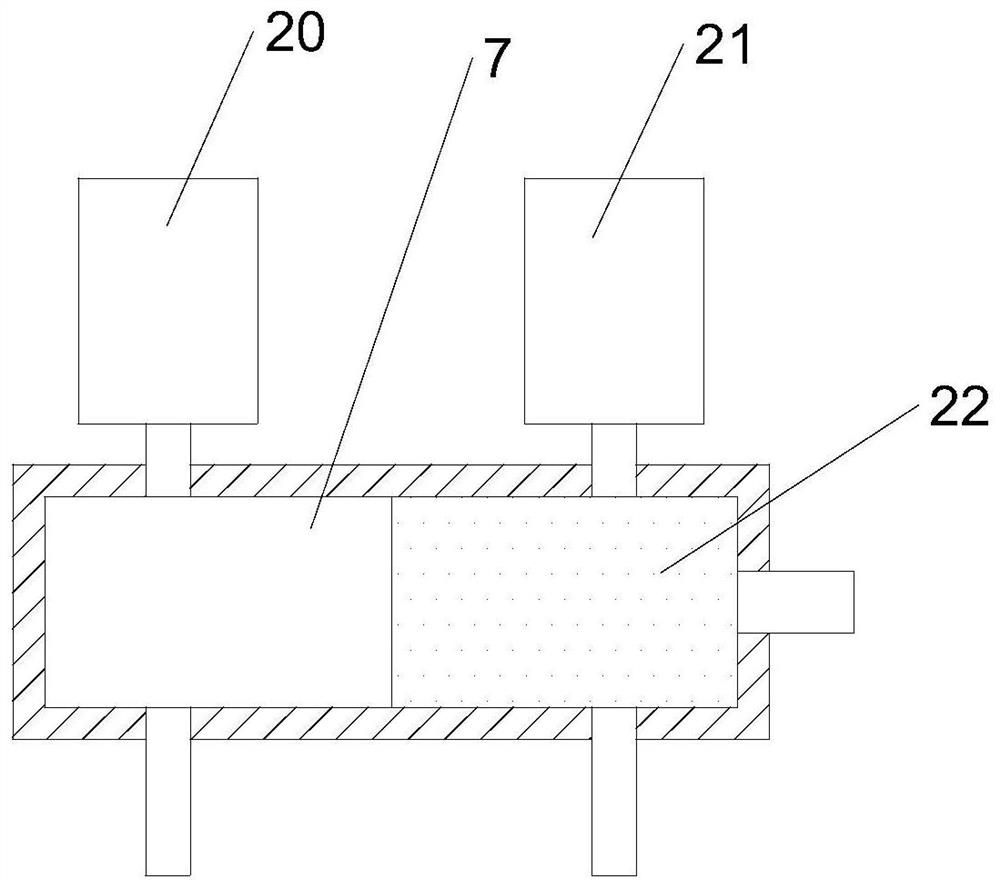

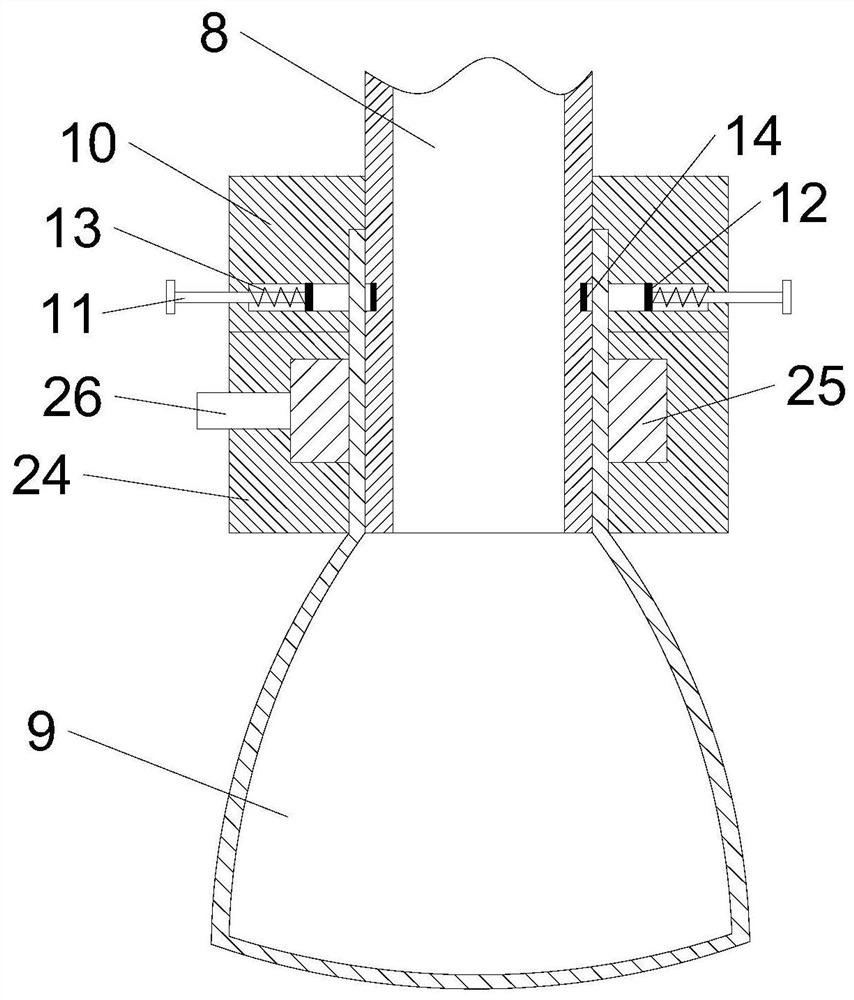

[0034] Please refer to Figure 1 to Figure 3 As shown, this embodiment provides a rice vacuum packaging machine with accurate metering, including a base 1, a frame 2, a hopper 3, a first cylinder 4, a second cylinder 5, a first piston chamber 6 and a second piston chamber 7, The frame 2 includes a vertical bar 201 and a top plate 202, the bottom of the vertical bar 201 is welded to the base 1, the top of the vertical bar 201 is welded to the bottom of the top plate 202, a round hole is provided in the middle of the top plate 202, and the hopper 3 is in the shape of a funnel, the hopper 3 is installed in the round hole, and the upper bottom of the hopper 3 is integrally formed with a hard square discharge pipe 8, and a switch valve 29 is installed on the discharge pipe 8, and the discharge pipe The bottom of 8 is sleeved with a packaging bag 9, specifically: the outer wall of the discharge pipe 8 is welded with a pocket fixing piece, and the bottom of the pocket fixing piece is...

Embodiment 2

[0041] Such as Figure 1 to Figure 4 As shown, this embodiment provides a rice vacuum packaging machine with accurate metering. In addition to all the technical features in Embodiment 1, the difference lies in: the base 1 is provided with a moving assembly, specifically: the bottom of the base 1 is provided with The second groove, the moving assembly includes a screw shaft 30, a moving wheel installation shaft 31 and a moving wheel 32, the screw shaft 30 is rotatably installed in the second groove, and the screw shaft 30 is in contact with the groove wall of the second groove Rolling bearings are installed between them, the left and right sides of the screw shaft 30 are symmetrically processed with threads in opposite directions, the two ends of the screw shaft 30 are threaded and installed with a shaft sleeve 33, and a strut 34 is hinged on the shaft sleeve 33, and the moving wheel is mounted on the shaft 31 Hinged on the hinge seat fixed on the inner wall of the second groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com