Device for concrete production weighing bin adhering prevention

A weighing device, anti-adhesion technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problem of affecting the accuracy of concrete mixture proportioning, affecting the quality of concrete production, and reducing the conveying function of weighing bins, etc. problems, to achieve the effect of saving manual cleaning costs, improving accuracy and production efficiency, and alleviating metal fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

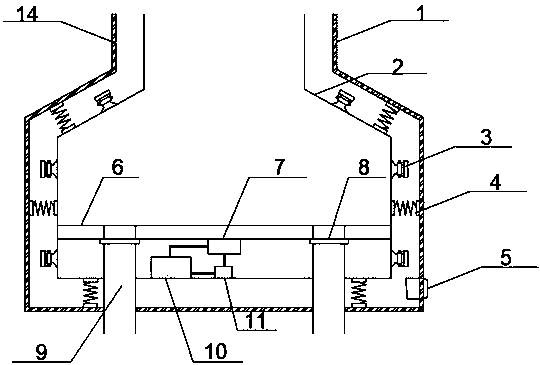

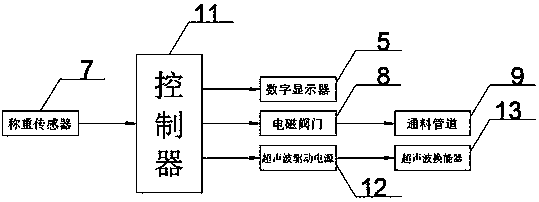

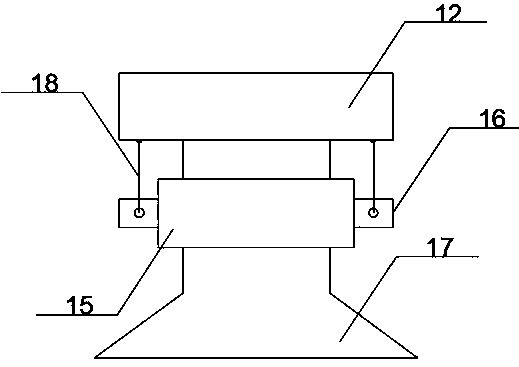

[0013] In order to further understand the implementation objectives, technical solutions and advantages of the present invention, the present invention will be described more fully below with reference to the relevant drawings.

[0014] like figure 1 The shown anti-adhesion device for weighing bins in concrete production includes a bin body, a weighing device and an anti-adhesion device, wherein the bin body includes an inner chamber 2 and an outer chamber 1; The bottom of the heavy bin includes a load cell 7 , a controller 11 , a bearing plate 6 , an electromagnetic valve 8 and a power supply 10 ; the anti-adhesion device includes several ultrasonic generators 3 and several return springs 4 .

[0015] In this embodiment, the silo body is cylindrical, with a feed inlet at the top, the feed inlet is funnel-shaped, and two discharge pipes 9 are symmetrically arranged at the bottom of the silo body with respect to the central axis, forming a buffer when feeding and discharging ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com