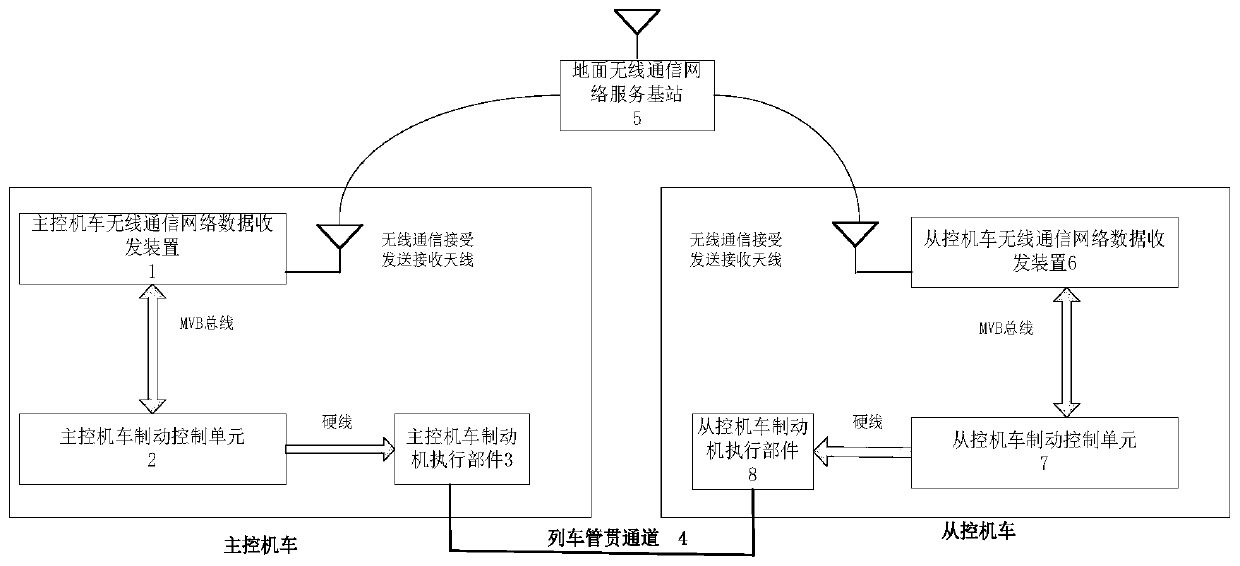

Train pipe synchronous control method and system for heavy-haul combination train

A technology of synchronous control and train management, applied in the general control system, control/regulation system, program control, etc., can solve the problems of large longitudinal impulse of trains, affecting train safety and operating efficiency, and poor vehicle synchronization, so as to improve safety , avoid frequent changes, and ensure the effect of flexibility and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

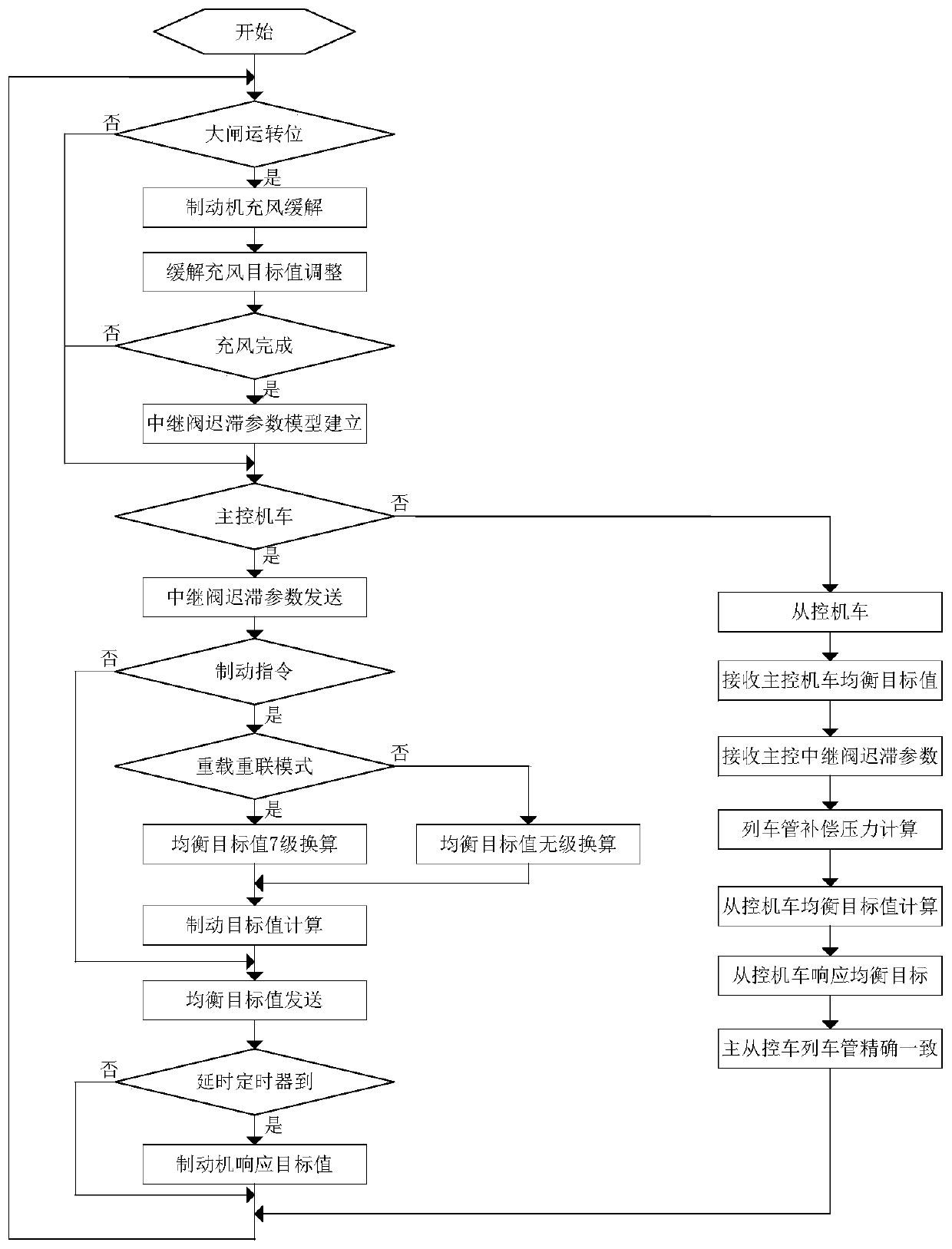

[0034] The main realization process of the present invention is as follows:

[0035] (1) First, judge whether the locomotive brake is in the running position. If it is the running position for air charging, set the target value of air charging higher than the constant pressure value of 600kPa, and set the target value of 607kPa to eliminate the relay valve hysteresis and cause the train to The pipe pressure cannot reach the target pressure value of 600kPa.

[0036] (2) After the air filling at the operating position is completed, record the pressure of the balanced air cylinder of the brake and the pressure of the train pipe, calculate the difference between the pressure of the balanced air cylinder and the pressure of the train pipe, and obtain the hysteresis parameter of the relay valve of the locomotive brake. The master locomotive transmits the hysteresis parameter value of the relay valve of the master locomotive to the slave locomotive through wireless, and the slave loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com