A thin film growth component, method and LED preparation method

A thin film growth and component technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as large lattice stress and poor performance of LED devices, and achieve the effect of improving lattice stress, improving performance, and ensuring film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

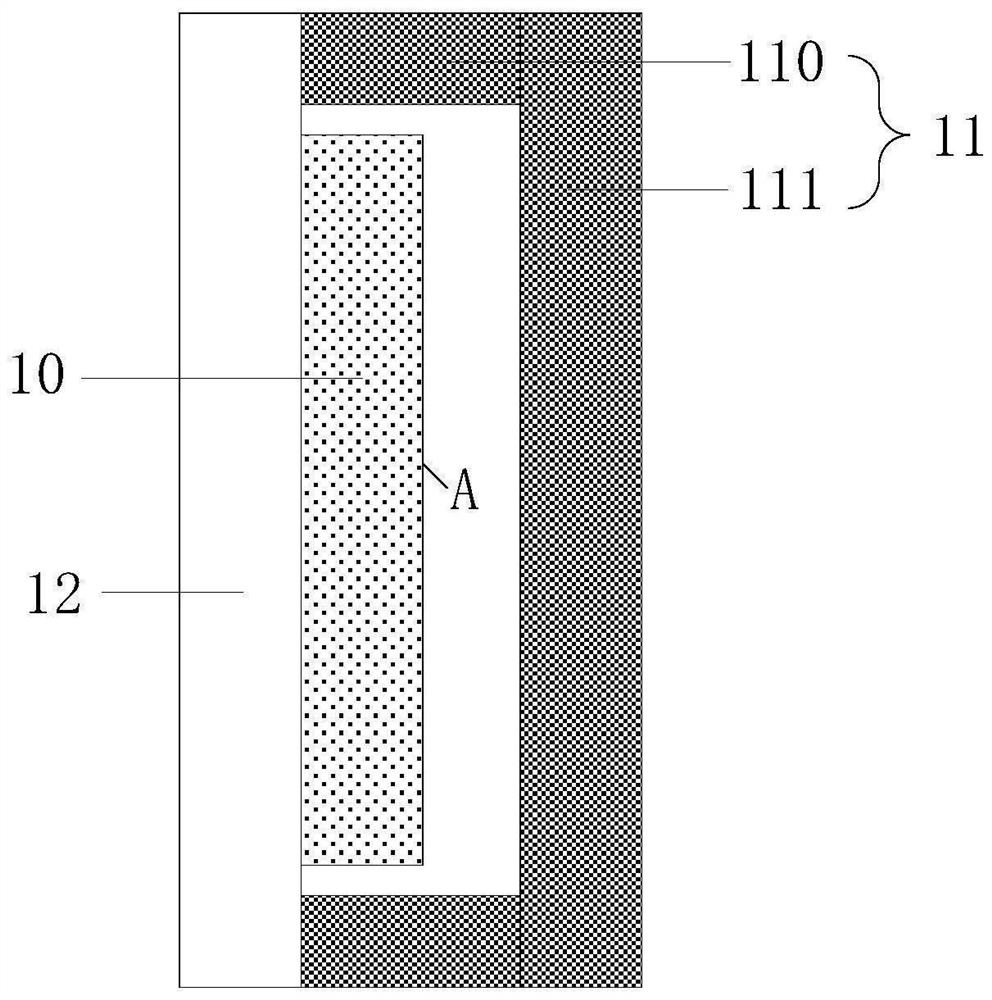

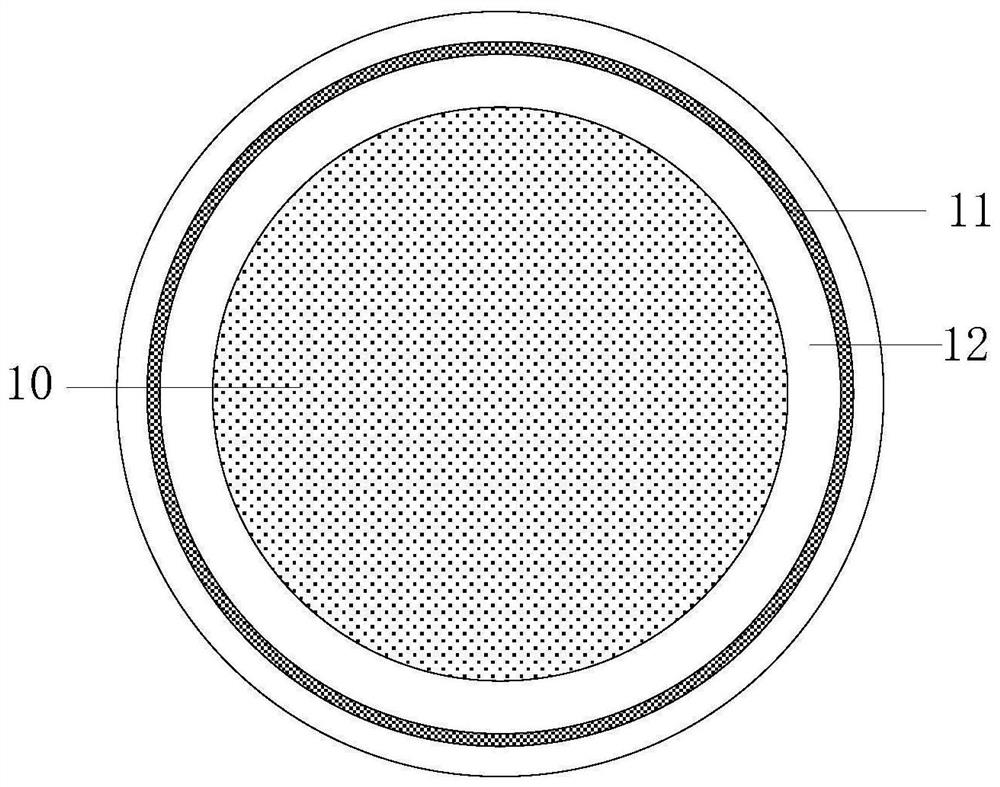

[0032] As mentioned in the background art, there is a huge lattice stress between the ALN buffer layer and the GaN thin film, which makes the performance of the LED device poor. The inventors found that the use of an AlGaN buffer layer can effectively improve the lattice stress of the GaN film. However, when an AlGaN buffer layer is fabricated by using an AlGa alloy target material, since the AlGa alloy is easily oxidized by water and oxygen in the air, the quality of the formed AlGaN buffer layer film is poor.

[0033] Based on this, the present invention provides a thin film growth assembly to overcome the above-mentioned problems in the prior art, including a target and a protective cover, the protective cover is detachably mounted on the target, and the protective cover A closed cavity is formed with the target, so as to seal the sputtering surface of the target in the closed cavity.

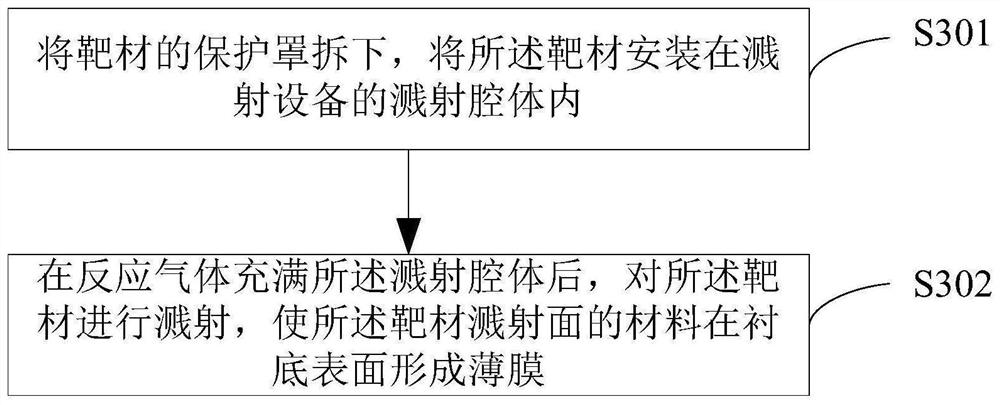

[0034] The thin film growth component, method and LED preparation method provided by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com