Lead-acid storage battery pack remote monitoring and online repairing system based on internet of things and cloud platform

A lead-acid battery, remote monitoring technology, used in the repair/maintenance of secondary batteries, transmission systems, secondary batteries, etc., can solve the problems of difficult uploading of measurement data, battery deterioration, and battery inconsistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

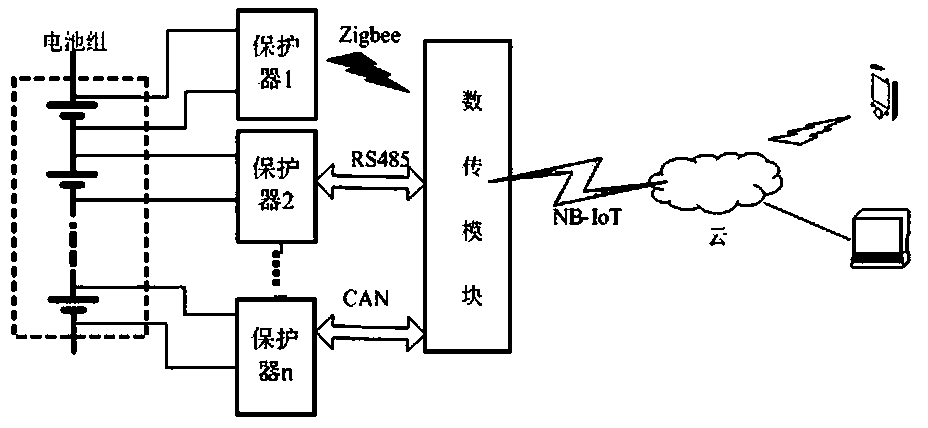

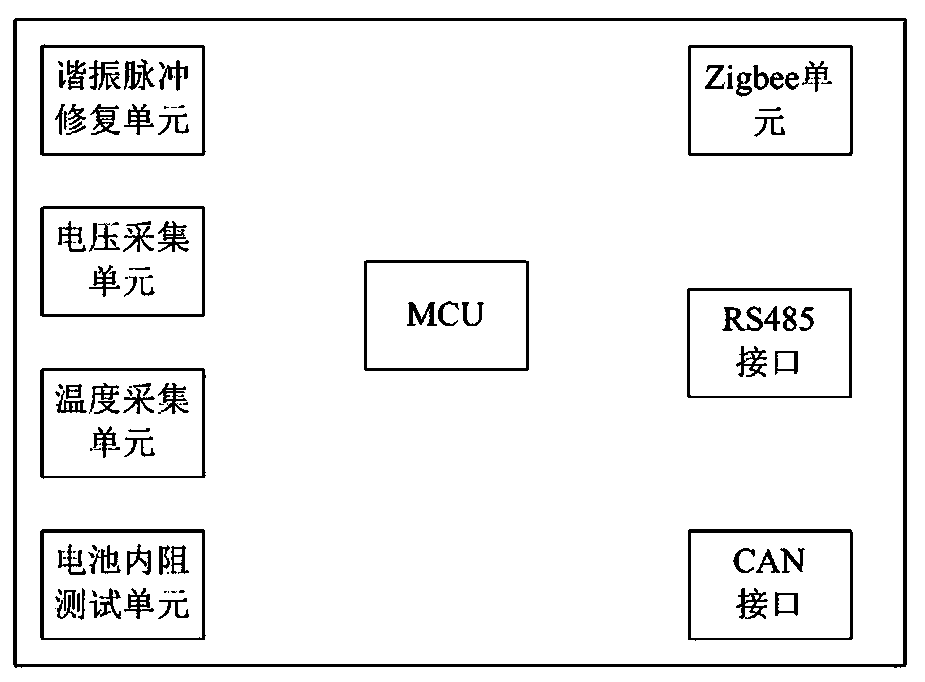

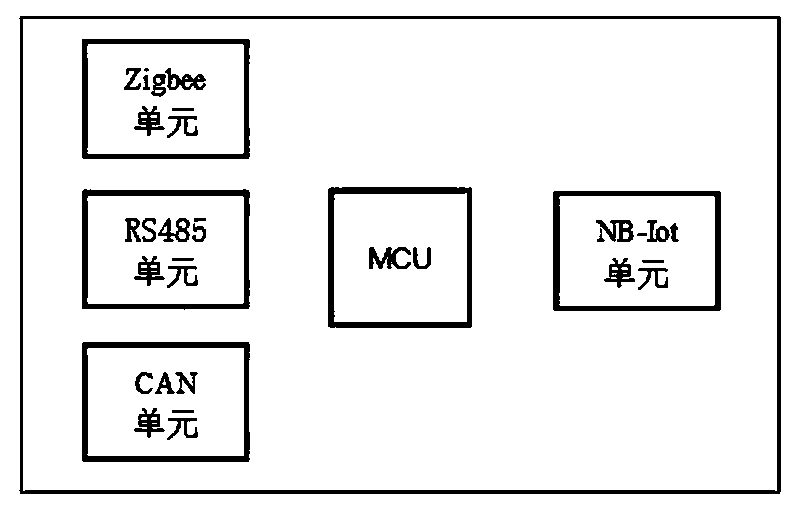

[0032] Embodiment 1 is a remote monitoring and online repair system for lead-acid battery packs based on the Internet of Things and cloud platform, such as figure 1 As shown, it includes a battery state monitoring device and an online battery repair device distributed at each lead-acid battery pack; a data transmission module that uses the Internet of Things to communicate with the cloud platform, and the data transmission module uses wired or wireless communication to communicate with the battery state The monitoring device communicates with the battery online repair device, uploads the state parameters of the lead-acid battery collected by the battery status monitoring device to the cloud platform, and receives commands from the cloud platform to control the battery online repair device to perform online repair on the lead-acid battery. The wired or wireless communication device between the data transmission module, the battery status monitoring device and the battery online ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com