Medical spring ring and manufacturing method and using method thereof

A technology of spring coils and coils, which is applied in the field of medical devices, can solve problems such as the inability to change the softness of spring coils, and achieve the effects of improving safety and treatment effects, reducing the risk of rupture, and not being easy to compress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

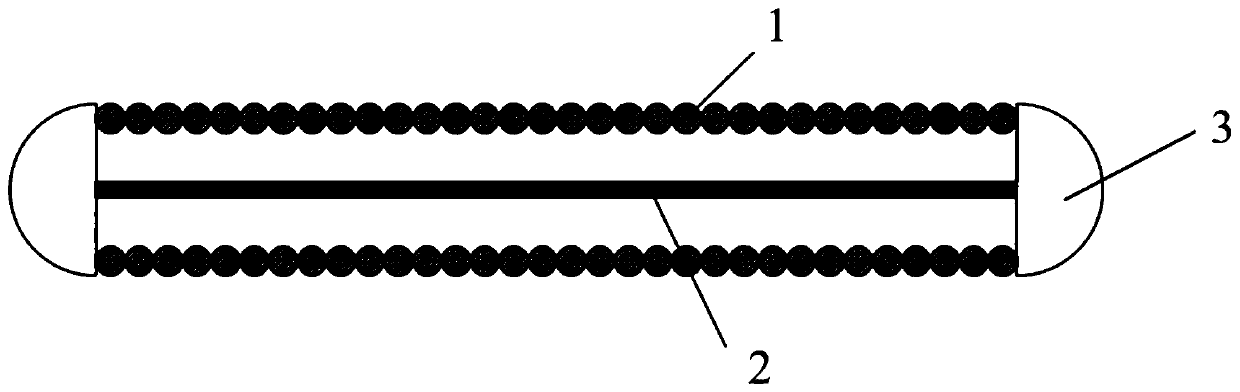

[0042] Please refer to figure 1, the present embodiment provides a medical coil for embolization of luminal lesion sites such as aneurysms, including not only a first coil 1 but also an anti-untwisting component 2 . The first coil 1 may be wound from a metal wire, which may not have the ability to change the stiffness under a set trigger condition. The first coil 1 can be a primary coil, such as a tubular spring structure, and the anti-untwisting component 2 can be a wire-like structure with one or more strands, and is arranged along the axial direction of the first coil 1 at the second In a coil 1 , it can also be said that the anti-untwisting component 2 is arranged in the cavity of the tubular spring structure of the first coil 1 . The two ends (ie the proximal end and the distal end) of the anti-unrotation component 2 are fixedly connected to the two ends (ie the proximal end and the distal end) of the first coil 1 respectively, that is, the proximal end and the first end...

Embodiment 2

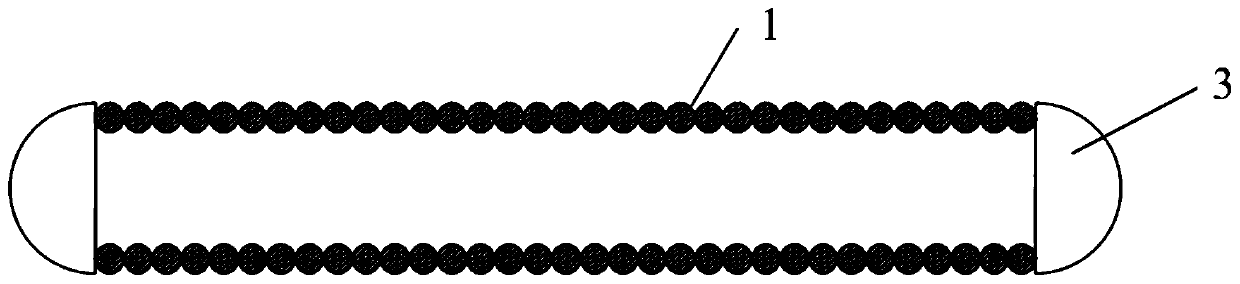

[0062] Please refer to figure 2 , the present embodiment provides a medical coil, which is used for the embolization of luminal lesions such as aneurysms, and has a first coil 1. The first coil 1 can be a primary coil, such as a tubular spring structure. The first Both ends of the coil 1 are respectively connected with a connection mechanism 3, such as a tubular, cap-shaped or hook-shaped fastener, which is welded to both ends of the first coil 1 by welding to strengthen the medical coil mechanical properties; the connecting mechanism 3 can also be a structure formed by adhesive, which is bonded to both ends of the first coil 1 .

[0063] The difference between the medical coil of this embodiment and the medical coil of Embodiment 1 is that the anti-unrotation component is omitted, and part or all of the first coil 1 is made of a material with variable stiffness under the set trigger conditions . The material with variable stiffness under the set triggering conditions may b...

Embodiment 3

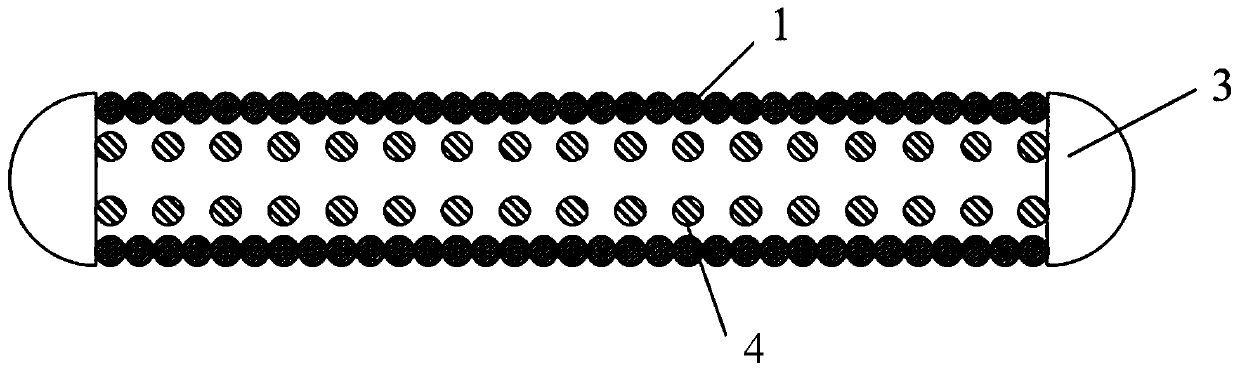

[0072] Please refer to image 3 , this embodiment provides a medical coil, which is used for embolization of luminal lesion sites such as aneurysms, and not only has a first coil 1 , but also has a second coil 4 . The first coil 1 may be wound from a metal wire, which may not have the ability to change its stiffness under a set trigger condition. Both the first coil 1 and the second coil 4 are primary coils, such as tubular spring structures, the outer diameter of the second coil 4 is smaller than the inner diameter of the first coil 1, and the second coil 4 is arranged in the first coil 1 (i.e. the second coil 4 is nested in the lumen of the first coil 1), and the two ends (i.e. the near end and the far end) of the second coil 4 are respectively connected to the two ends (i.e. the near end and the far end) of the first coil 1 The distal end) is fixedly connected, that is, the proximal end of the second coil 4 is fixedly connected with the proximal end of the first coil 1 , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com