Sewage separation device for kitchen sink

A separation device and kitchen sink technology, applied in the directions of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of low discharge efficiency of impurity filtration and separation of sewage, small filter area, time-consuming and labor-intensive, etc. The effect of large area and improved emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

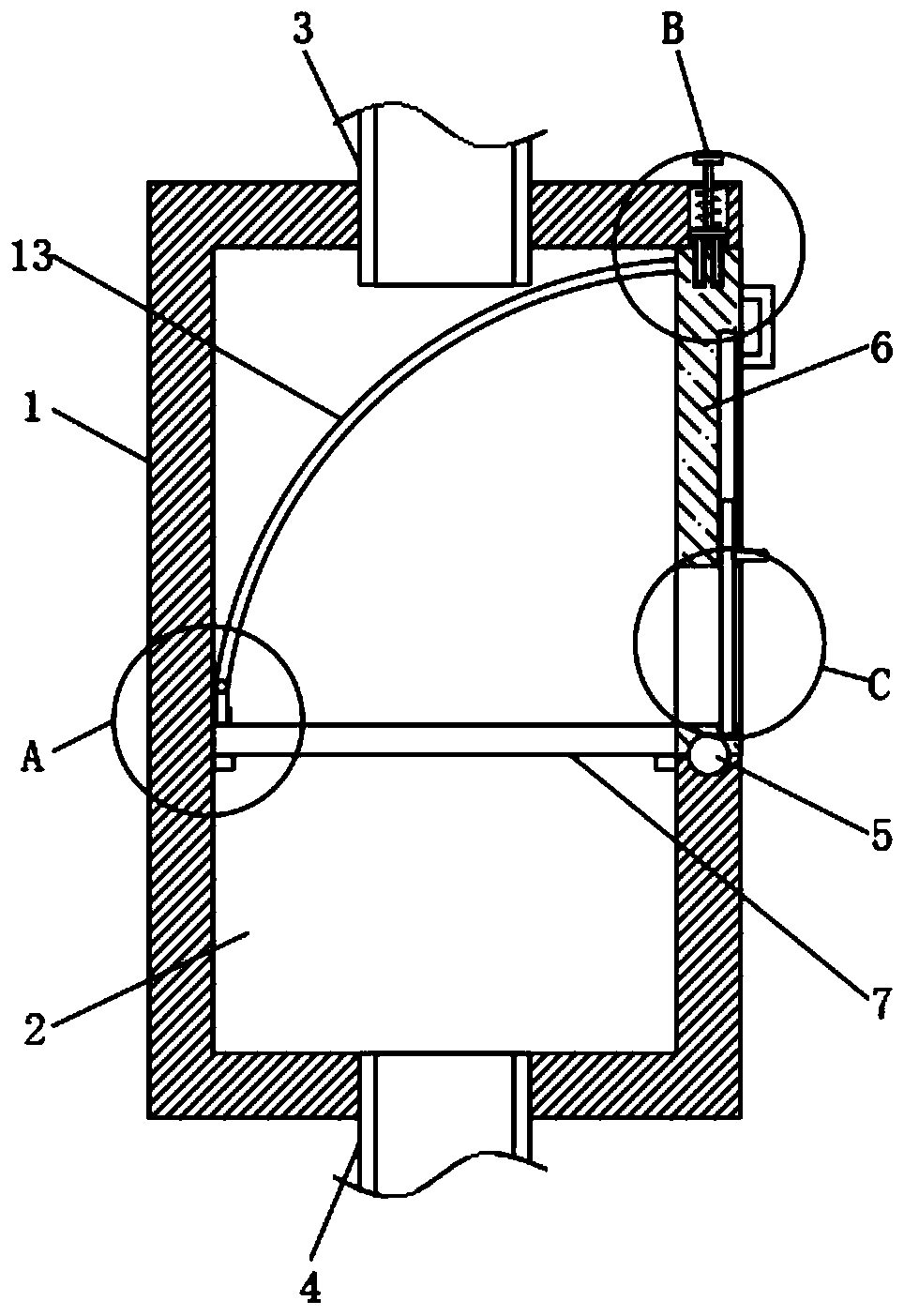

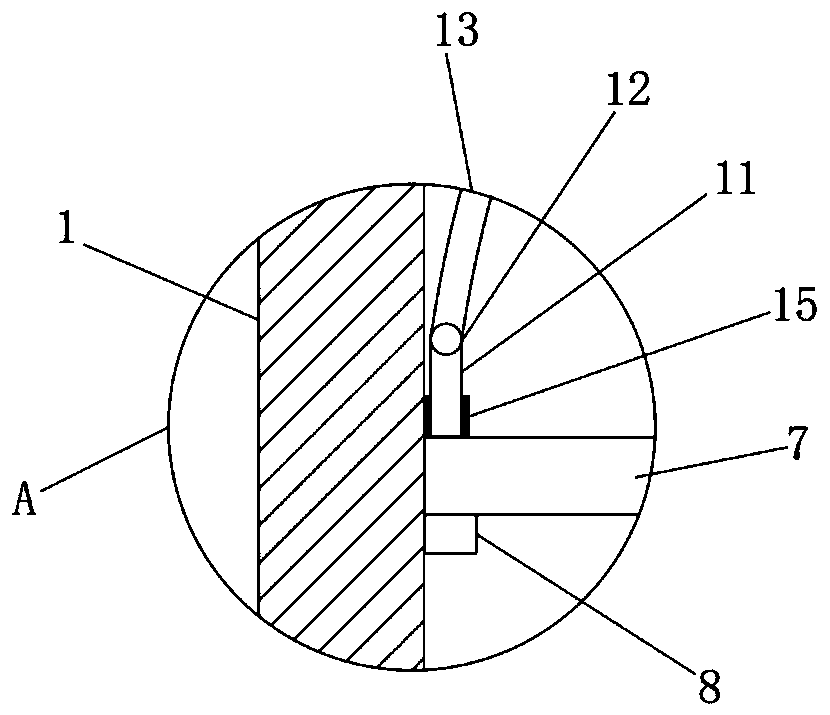

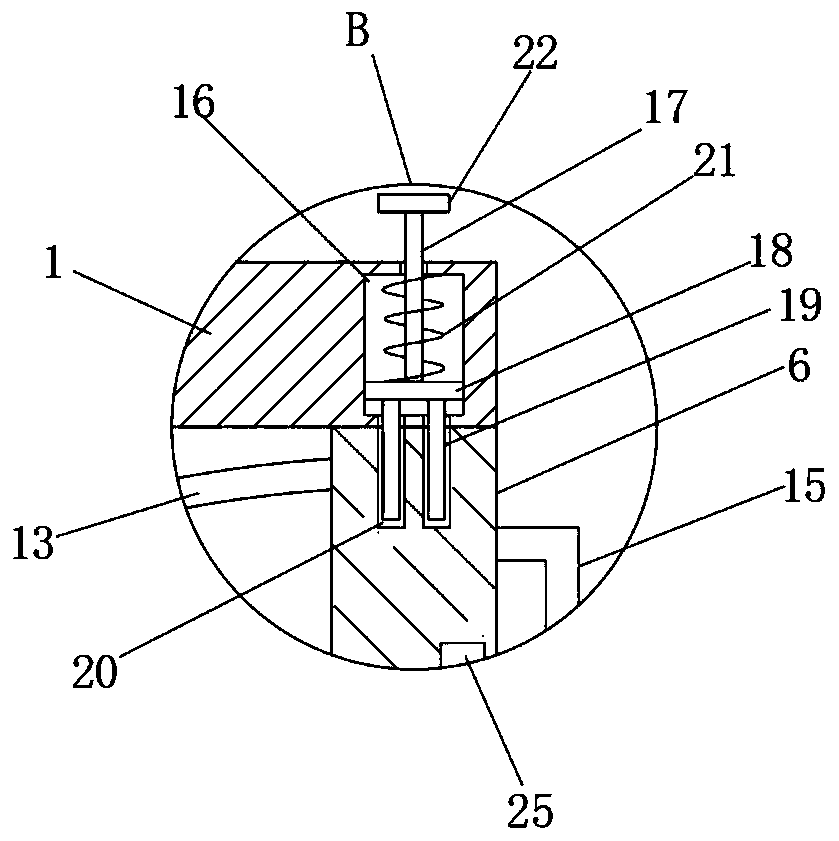

[0032] refer to Figure 1-8 , a sewage separation device for a kitchen sink, comprising a body 1, a hollow cavity 2 is arranged in the body 1, a water inlet 3 is penetrated through the upper end side wall of the body 1, and the drain pipe of the kitchen sink is communicated with the water inlet 3, The sewage containing more impurities in the kitchen sink enters the hollow cavity 2 through the water inlet 3. The lower end side wall of the body 1 is provided with a drainage outlet 4, which can connect the drainage outlet 4 with the sewer. One side wall of the body 1 is provided. A side door 6 is rotatably connected to the upper through the rotating shaft 5, a handle is fixedly connected to the side wall of the side door 6, a partition plate 7 is fixedly connected to the side wall of the side door 6 close to the hollow cavity 2, and the opposite inner walls of the hollow cavity 2 are fixedly connected. There is a placing block 8, the lower end side wall of the clapboard 7 is in c...

Embodiment 2

[0038] refer to Figure 9-12 , the opposite side walls of the hollow cavity 2 are respectively inclined with a third chute 29 and a fourth chute 30, the fourth chute 30 penetrates the inner wall of the hollow cavity 2, the third chute 29 and the first arc chute 13 The fourth chute 30 is communicated with the second arc-shaped chute 14, one end of the pull rod 12 is slidably connected to the inner wall of the third chute 29, and the other end of the pull rod 12 is slidably connected to the inner wall of the fourth chute 30. Extending to the outside of the body 1, a second opening 31 is provided through the side wall of the partition 7 near one end of the side door 6, the inner wall of the second opening 31 is provided with a third opening 32, and a placing bucket 33 is slidably connected in the second opening 31. , the side wall of the placing bucket 33 is set as a filter screen, which can be used to drain the sewage from the impurities. The side door 6 drives the partition 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com