Method for enriching arsenic on high-arsenic crude lead refining slag

A crude lead refining and slagging technology, applied in the field of metallurgy, can solve the problems of large amount of slag, high lead content in scum, low arsenic enrichment rate, etc., and achieve the effect of simple process, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

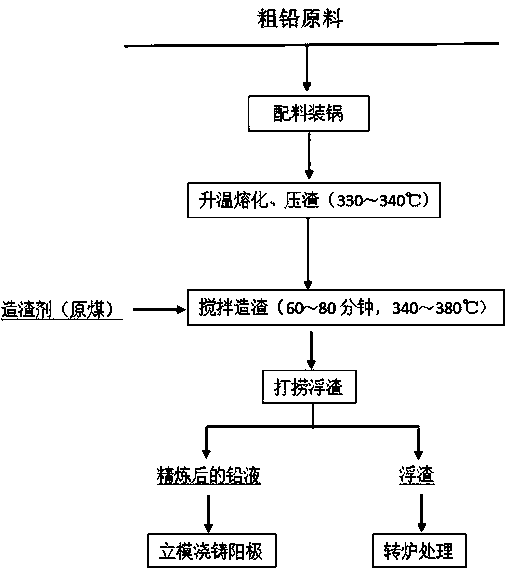

Image

Examples

Embodiment 1

[0017] According to the weight ratio, 18.42% Isa furnace crude lead, 78.2% reduction furnace crude lead, and 3.7% converter crude lead are used in the pot, and the environmental dust collection cover is covered after filling once. The average composition of the material in the pot is: Pb : 97.20%, Ag: 887g / t, Cu: 0.21%, Sb: 0.69%, As: 1.15%; heat up and melt, when the temperature of the lead liquid reaches 330°C, start slag pressing, and stir when the temperature reaches about 340°C; stir for 8 minutes Finally, add a certain amount of slagging agent (raw coal) into the pot manually to stir and make slagging; after stirring for 70 minutes, observe that the scum changes loosely, does not agglomerate, and is fine-grained when it is gray-black, indicating that the reaction is sufficient, stop Stirring, the final temperature of slagging is 375°C; the scum is removed, and the scum is processed in the converter after sampling and analysis; the lead liquid after slagging is pumped into...

Embodiment 2

[0021] According to the weight ratio, 18.38% Isa furnace crude lead, 78.22% reduction furnace crude lead, and 3.40% converter crude lead are used in the pot, and the environmental dust collection cover is covered after filling once. The average composition of the material in the pot is: Pb : 96.73%, Ag: 910g / t, Cu: 0.19%, Sb: 0.61%, As: 1.07%; heat up and melt, when the temperature of the lead liquid reaches 332°C, start slag pressing, and stir when the temperature reaches about 341°C; stir for 10 minutes Finally, add a certain amount of slagging agent (raw coal) into the pot manually to stir and make slagging; after stirring for 75 minutes, observe that the scum changes loosely, does not agglomerate, and is fine-grained when it is gray-black, indicating that the reaction is sufficient, stop Stirring, the temperature at the end point of slagging is 378°C; the scum is removed, and the scum is processed in the converter after sampling and analysis; the lead liquid after slagging ...

Embodiment 3

[0025] According to the weight ratio, 18.32% Isa furnace crude lead, 78.16% reduction furnace crude lead, and 3.52% converter crude lead are used in the pot, and the environmental dust collection cover is covered after filling once. The average composition of the material in the pot is: Pb : 97.33%, Ag: 1204g / t, Cu: 0.22%, Sb: 0.64%, As: 0.94%; heat up and melt, when the temperature of the lead liquid reaches 333°C, start slag pressing, and stir when the temperature reaches about 342°C; stir for 10 minutes Finally, a certain amount of slagging agent (raw coal) is manually added into the pot for stirring and slagging; after stirring for 78 minutes, observe that the scum changes loosely, does not agglomerate, and is fine-grained when it is gray-black, indicating that the reaction is sufficient, stop Stirring, the final temperature of slagging is 380°C; the scum is removed, and the scum is processed in the converter after sampling and analysis; the lead liquid after slagging is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com