Preparation method of full-wool wash and wear fabric

A fabric and washable technology, which is applied in the production field of washable and wearable fabrics, can solve the problems of poor machine-washing resistance of wool fabrics, and achieve the effects of improving hand feeling, good anti-wrinkle effect and stable modeling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

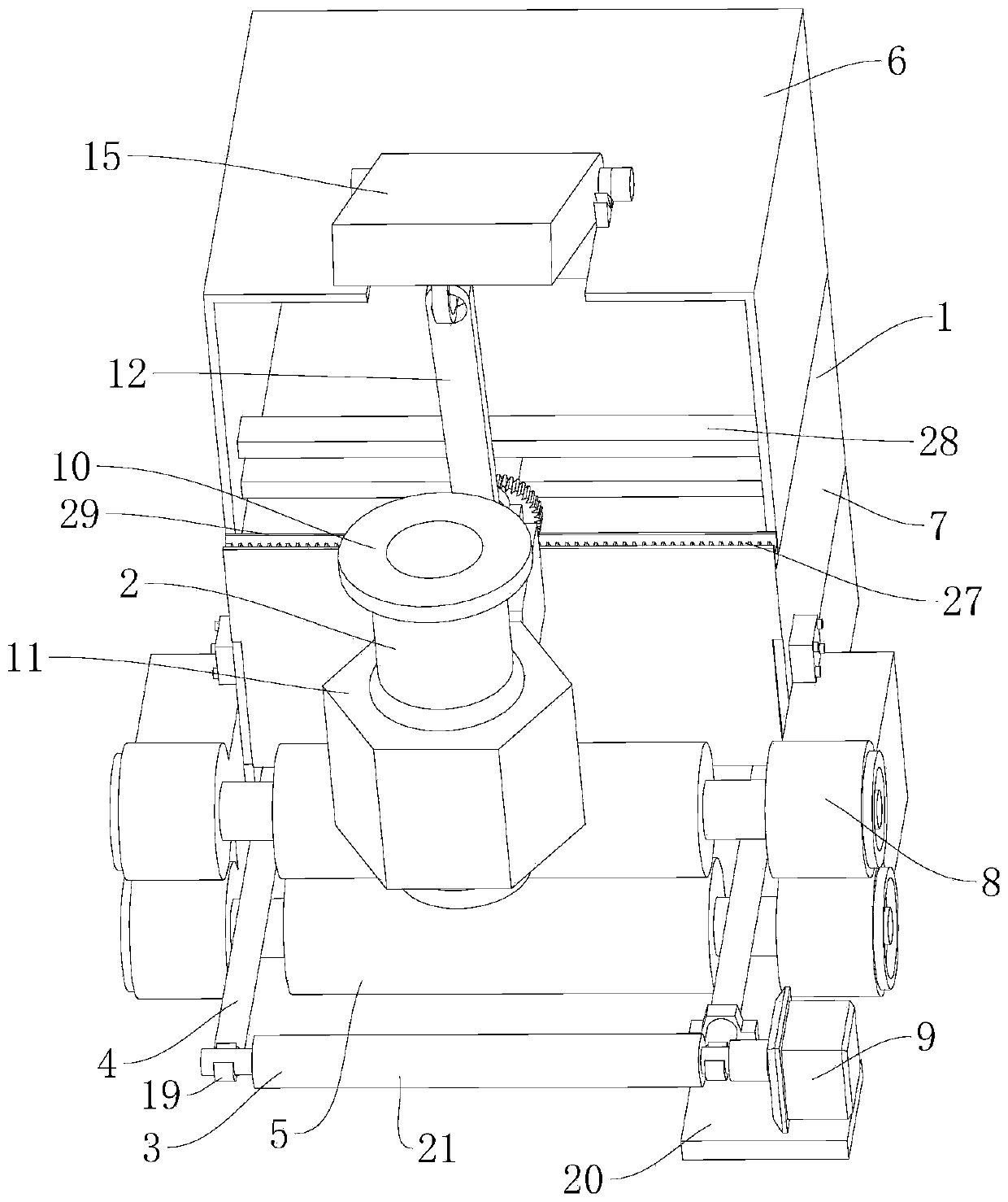

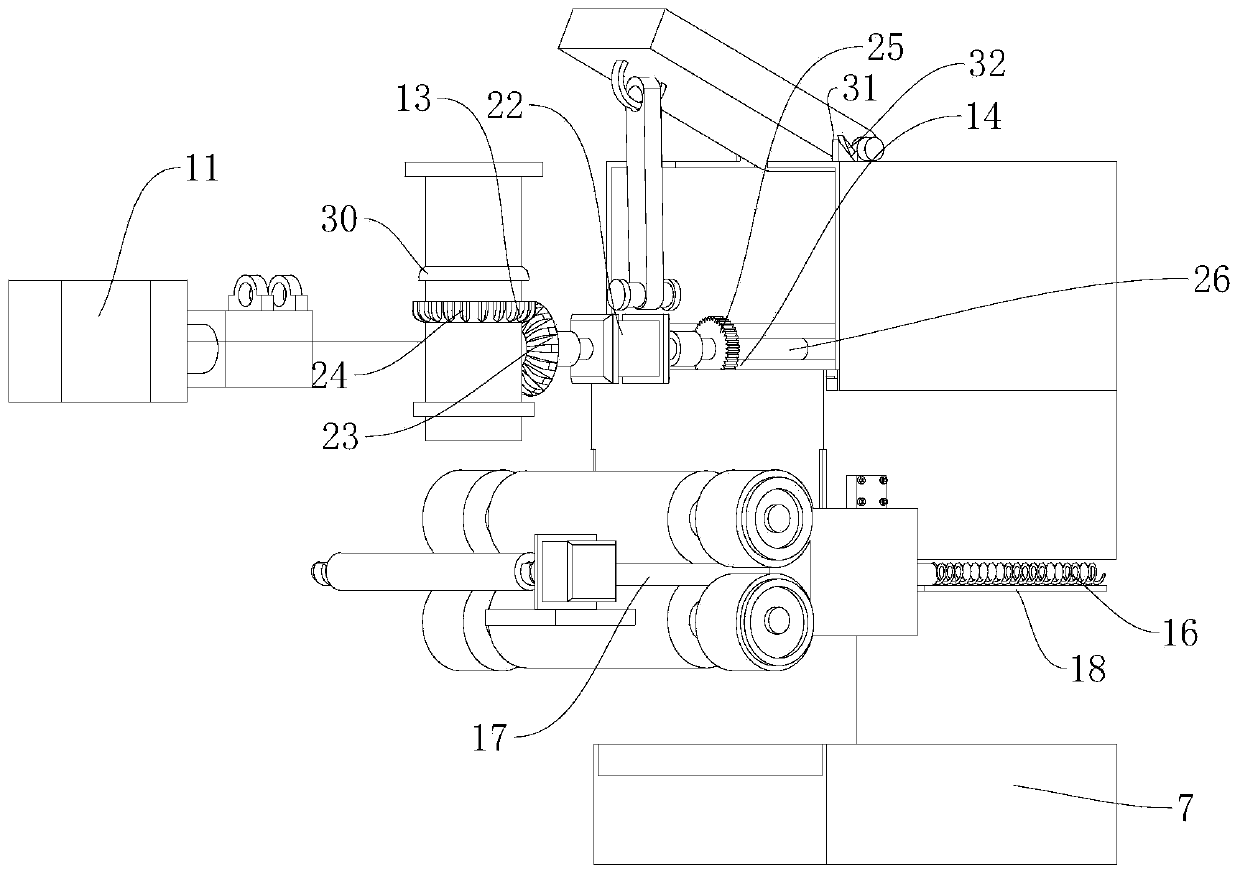

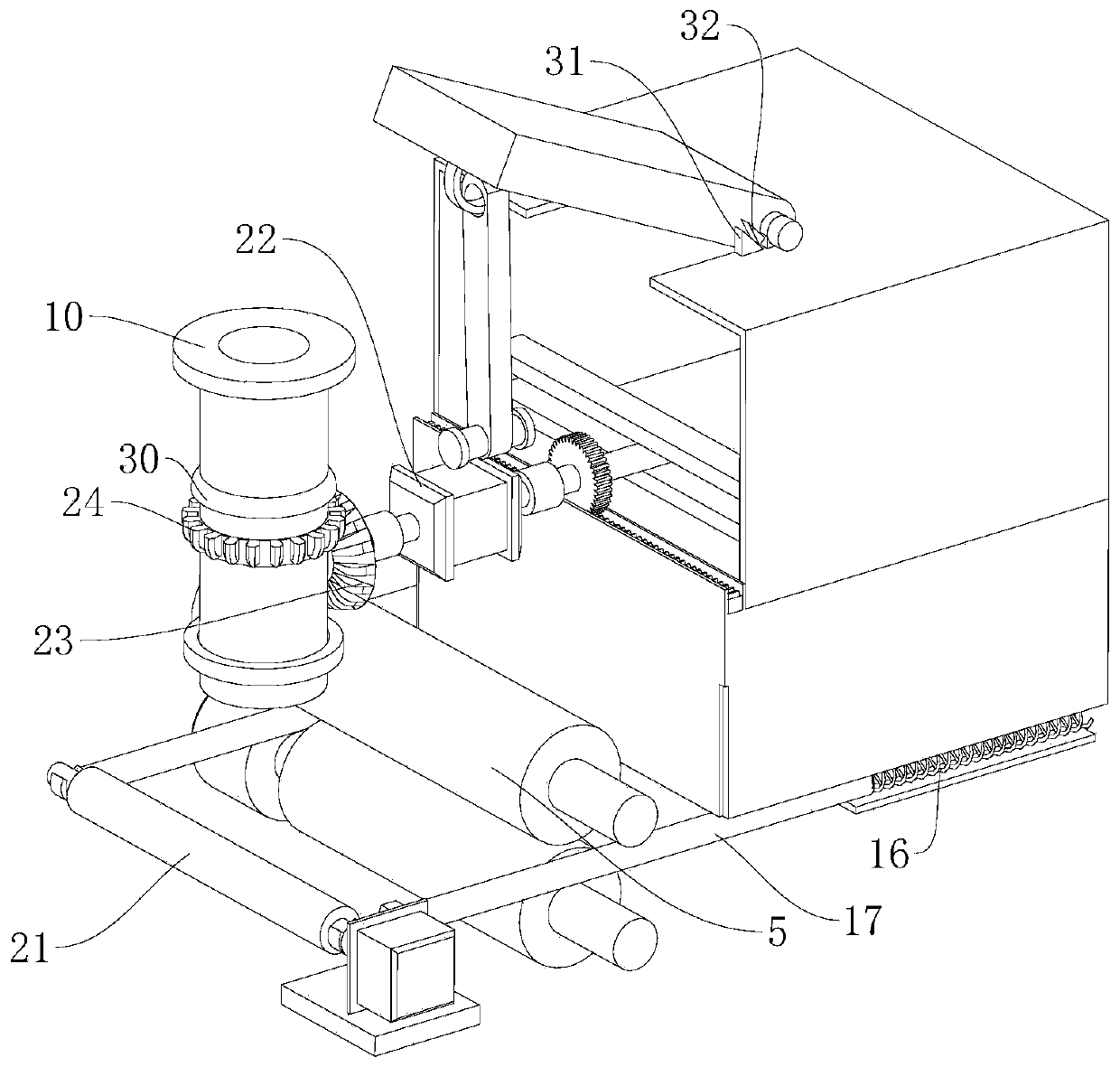

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0029] The preparation method of the all-wool washable wearable fabric is as follows: dyeing→rewashing→recombing→pre-spinning→spinning→self-winding→doubling→two-for-one twisting→steaming yarn→warping→weaving→grey fabric inspection → finishing → finished product;

[0030] The raw material of the all-wool washable fabric is 70S Australian wool;

[0031] In the weaving step, the fabric structure is selected as a 3 / 1 warp double weave, and an unclear shed is used to make the heights between adjacent warp yarns different. And appropriately increase the tension of the upper machine. When warping and reversing, adopt the upper cooling pulp technology to reduce hairiness and reduce the adhesion between warp yarns;

[0032] The post-finishing specifically includes the following step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com