Deep narrow river valley super deep foundation pit muddy excavation road construction slope protection structure and method

A technology of road construction and construction method, which is applied in the direction of infrastructure engineering, roads, excavation, etc., can solve the problems of high construction cost and long construction period, so as to ensure anti-sliding stability, ensure bearing capacity, and ensure firm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

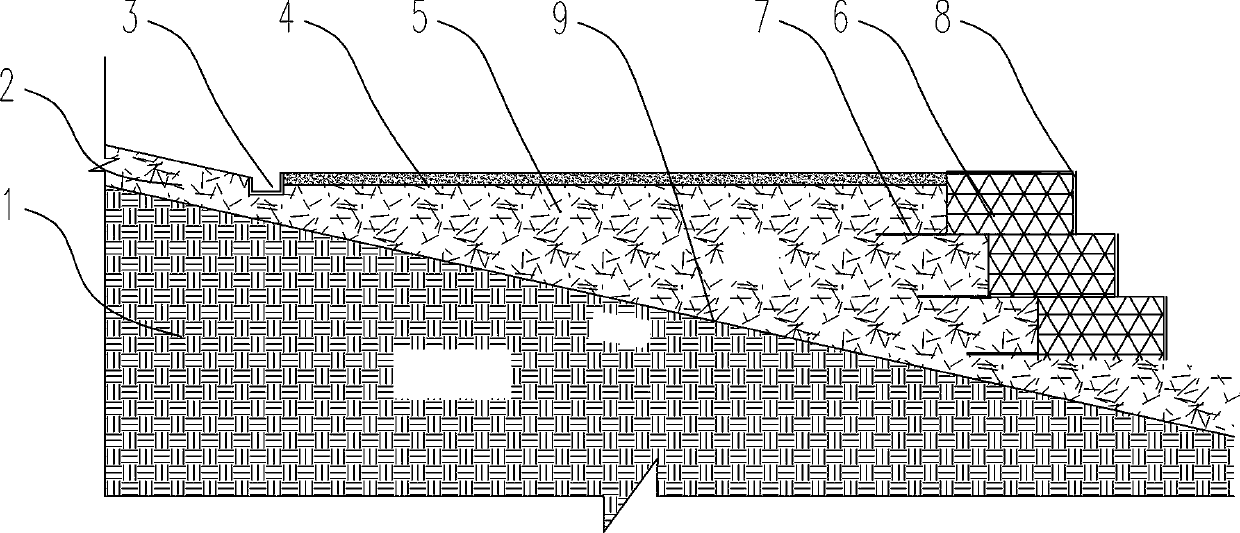

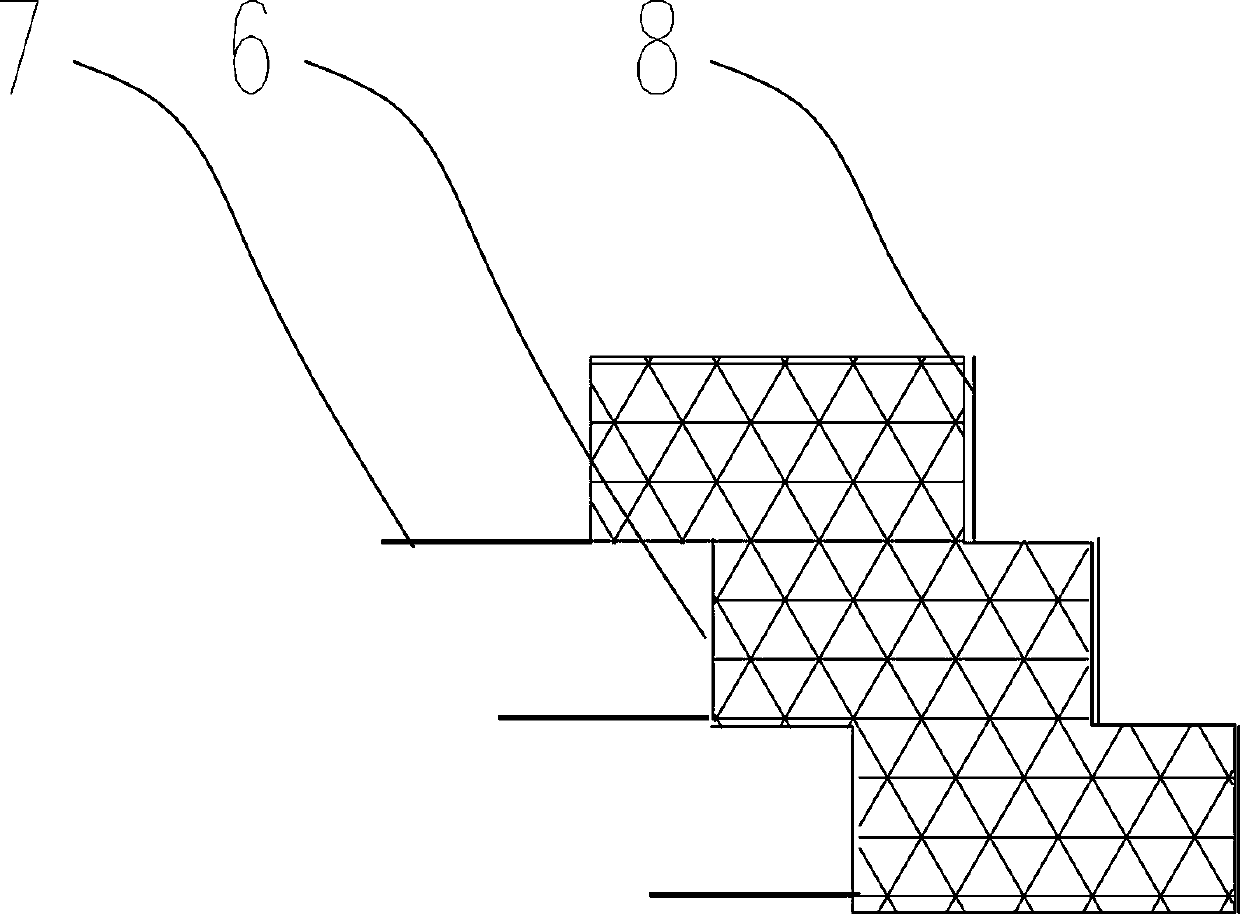

[0032] Such as Figure 1~3 Among them, a muddy excavation road construction slope protection structure for ultra-deep foundation pits in deep and narrow valleys, a gravel cushion 5 is arranged below the road surface 4, preferably, the thickness of the gravel cushion 5 is 1.5m~2m, A concrete drain 3 is provided on the side of the road surface 4 near the top of the slope, and a plurality of stacked steel gabions 6 are provided on the side of the road surface 4 near the bottom of the slope. The steel gabion 6 is a cage body welded by steel bars, and the cage body is filled with block stones.

[0033] In a preferred solution, a gravel revetment 2 is provided on the outside of the road surface 4 near the top of the slope, and the thickness of the gravel revetment 2 is 1 m. In a preferred solution, a geotextile 9 is also provided below the gravel slope protection 2 and the gravel cushion 5 . The geotextile 9 here is a geomembrane with a waterproof effect and a certain bearing capa...

Embodiment 2

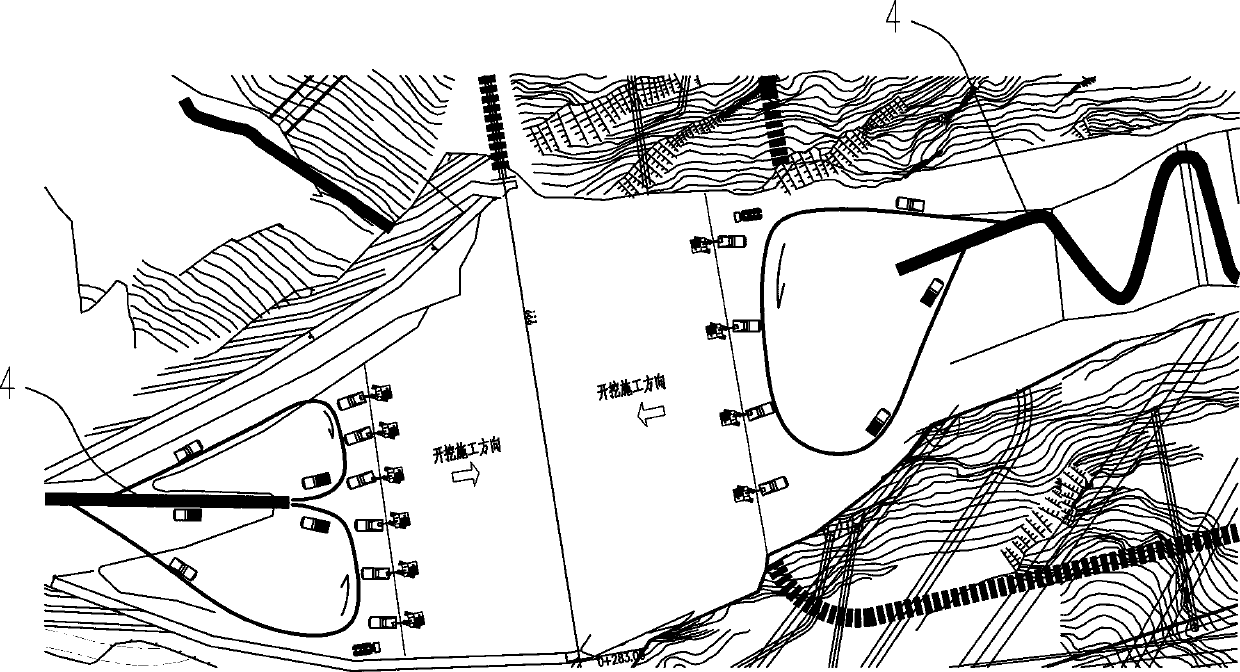

[0039] Such as Figure 1~3 Among them, a construction method using the above-mentioned deep and narrow valley ultra-deep foundation pit silt excavation road construction slope protection structure, comprising the following steps:

[0040] S1. Laying the gravel cushion 5; the laying thickness of the gravel cushion 5 is 1.5m~2m.

[0041] S2. Set excavation drainage ditch on one side of road surface 4. The bottom of the drainage ditch should be lower than the bottom of the proposed construction road surface 4. The drainage ditch is connected to the water collection well located at the lowest position in the foundation pit, and the water collection well is connected to the pump room for continuous drainage ;

[0042] After drainage makes the base reach sufficient bearing capacity, the concrete drainage ditch 3 is erected; the bottom of the concrete drainage ditch 3 is lower than the bottom of the road surface 4 to be laid, so as to continue to assist the drainage of the base.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com