Self-adhesive stress cloth

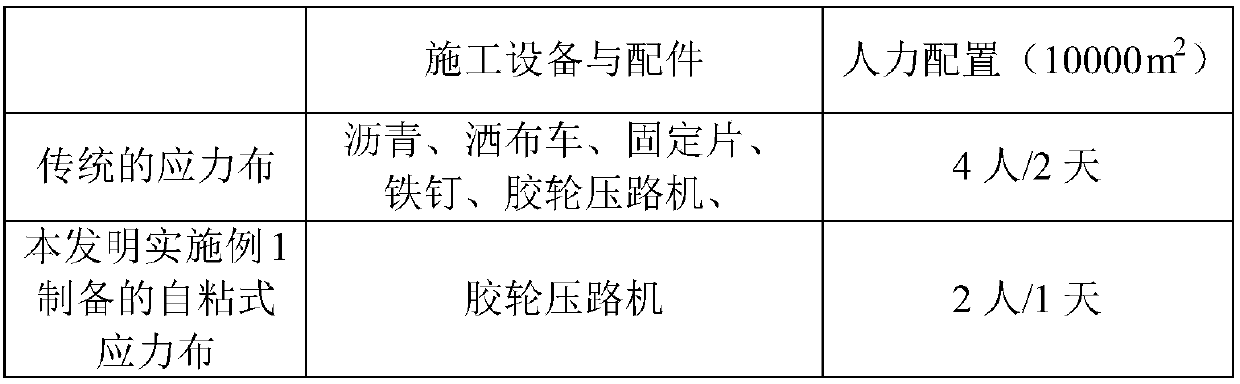

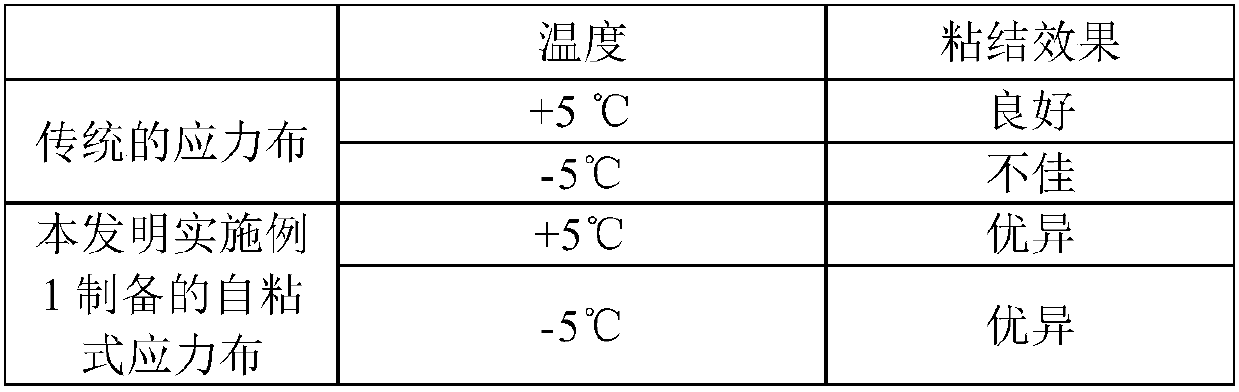

A self-adhesive, stress-based technology, which is applied in the direction of textiles and papermaking, roads, on-site paved coagulation pavements, etc., can solve the problem that the stress cloth cannot meet the rapid development of construction engineering, increase the workload of construction, and meet the urgent requirements of the construction period, etc. Problems, to achieve excellent adhesion, reduce the quantity, reduce the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A self-adhesive stress cloth, including a base cloth and a waterproof layer, the base cloth adopts a warp-knitted directional structure, and the base cloth is made of alkali-free glass fiber yarn (purchased from Taian Glass Fiber Co., Ltd.) and polyester glass fiber cloth (purchased from Taian Fiberglass Co., Ltd.) Composed of Kaifeng Sinoma New Building Materials Co., Ltd.), one side of the base fabric is covered with a waterproof layer. The waterproof layer is a waterproof layer of self-adhesive material. The waterproof layer of self-adhesive material is prepared according to the mass ratio of the following components at a temperature of 150°C and a pressure of 6.5MPA for 2 hours. SBS modified asphalt (purchased from Hebei Baoli Chemical Technology Co., Ltd. Co., Ltd.): elastic asphalt (purchased from Hebei Baoli Chemical Technology Co., Ltd.): EVA resin (purchased from Shanghai Jiahao Adhesive Products Co., Ltd.) is 5:4:1.

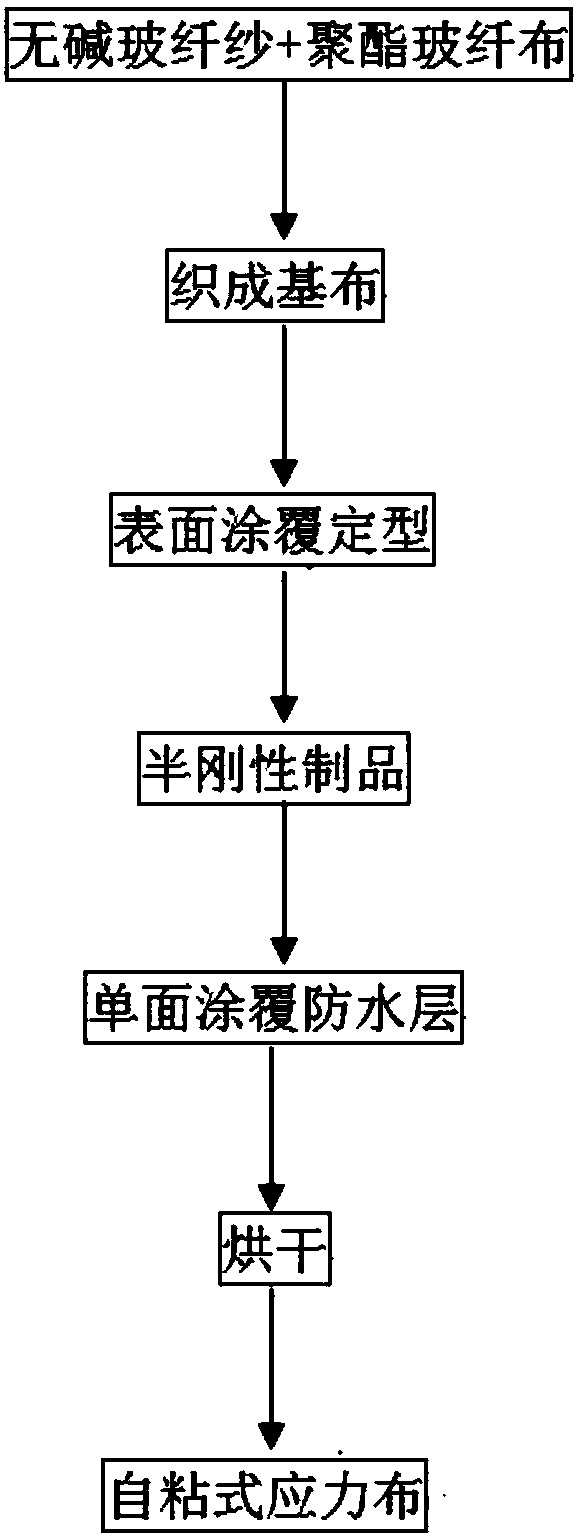

[0019] The process flow of self-adhesive s...

Embodiment 2

[0024] This example is basically the same as Example 1, except that the waterproof layer of the self-adhesive material is prepared by copolymerization at a temperature of 160°C and a pressure of 6.5MPA for 3 hours.

Embodiment 3

[0026] This example is basically the same as Example 1, except that the waterproof layer of the self-adhesive material is prepared by copolymerization at a temperature of 170°C and a pressure of 6.5MPA for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com