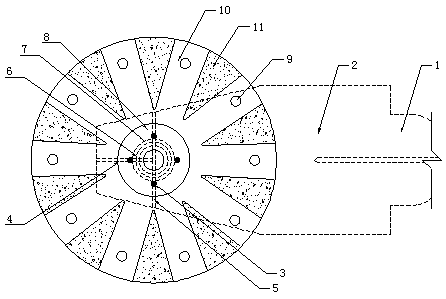

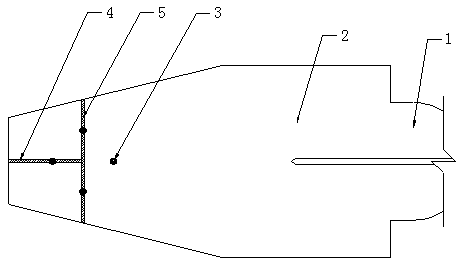

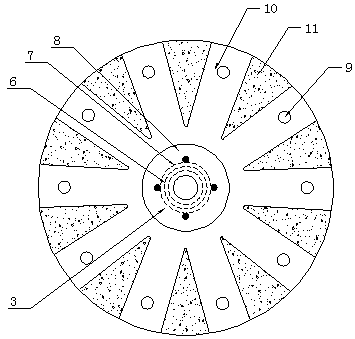

Circular pump station water collecting tank with uniform water distribution device

A technology of water distribution device and water collection tank, which is applied in the configuration of water supply device, water supply pool, construction, etc., can solve the problems of poor inflow conditions of pumps, uneven water distribution, and top flushing of water flow, so as to improve circumferential flow distribution, Uniform outflow, the effect of promoting uniform and smooth upward flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific implementation parameters are set as follows:

[0026] The pumping flow Q of the pumping station is 36.6m 3 / s, single pump flow rate Q' is 3.66m 3 / s, the inlet width B of the water distribution tank is 18m, the outlet width B′ is 8m, the height H of the water distribution box culvert at the orifice position is 2.20m, and the orifice diameter between the upper and lower layers of the sump is D 0 is 5m, the suspension height H of the longitudinal deflector 0 is 0.8m, the height of the top of both sides of the longitudinal guide plate to the bottom of the water distribution box culvert is 1.5m, the height of the middle plate of the longitudinal guide plate to the bottom of the water distribution box culvert is 3.9m, and the bottom elevation of the first laminate is h 1 and the clear distance h between the three laminates 2 、h 3 Both are 1.6m, the thickness h of the pressing plate is 0.3m, and the inner diameter of the first laminate is D 1 4.2m, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com