Sinking and laying process of large-diameter HDPE pipeline under complex offshore working condition

A technology with complex working conditions and large diameter, which is applied in the sewer pipeline system, pipeline laying and maintenance, waterway system, etc., to achieve the effects of reducing impact, reducing demand, improving efficiency and installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

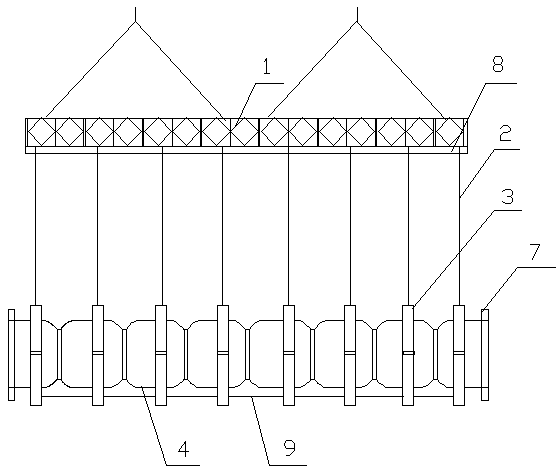

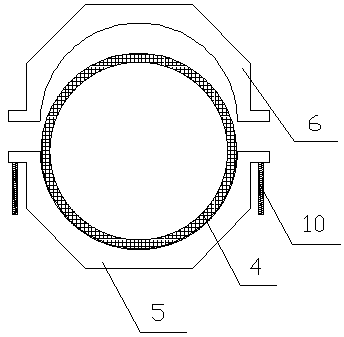

[0034] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0035] The present invention takes the construction of the supporting circulating water system of the XXX power plant project in the Philippines as an example, and its intake and drainage pipelines adopt HDPE structure. The outer diameter of HDPE pipe reaches 3.7m, which is the first case at home and abroad. After reviewing similar HDPE pipeline sinking cases, capsule floating and water injection sinking technology and pipe laying ship laying technology are mainly used at home and abroad. However, the above two processes have not installed large-diameter pipes with an inner diameter of more than 3m. In addition, the capsule floating, water injection and sinking instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com