Environment-friendly solid waste treatment device

A processing device, an environmentally friendly technology, applied in the field of environmentally friendly solid waste processing devices, can solve problems such as wasting time and reducing labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

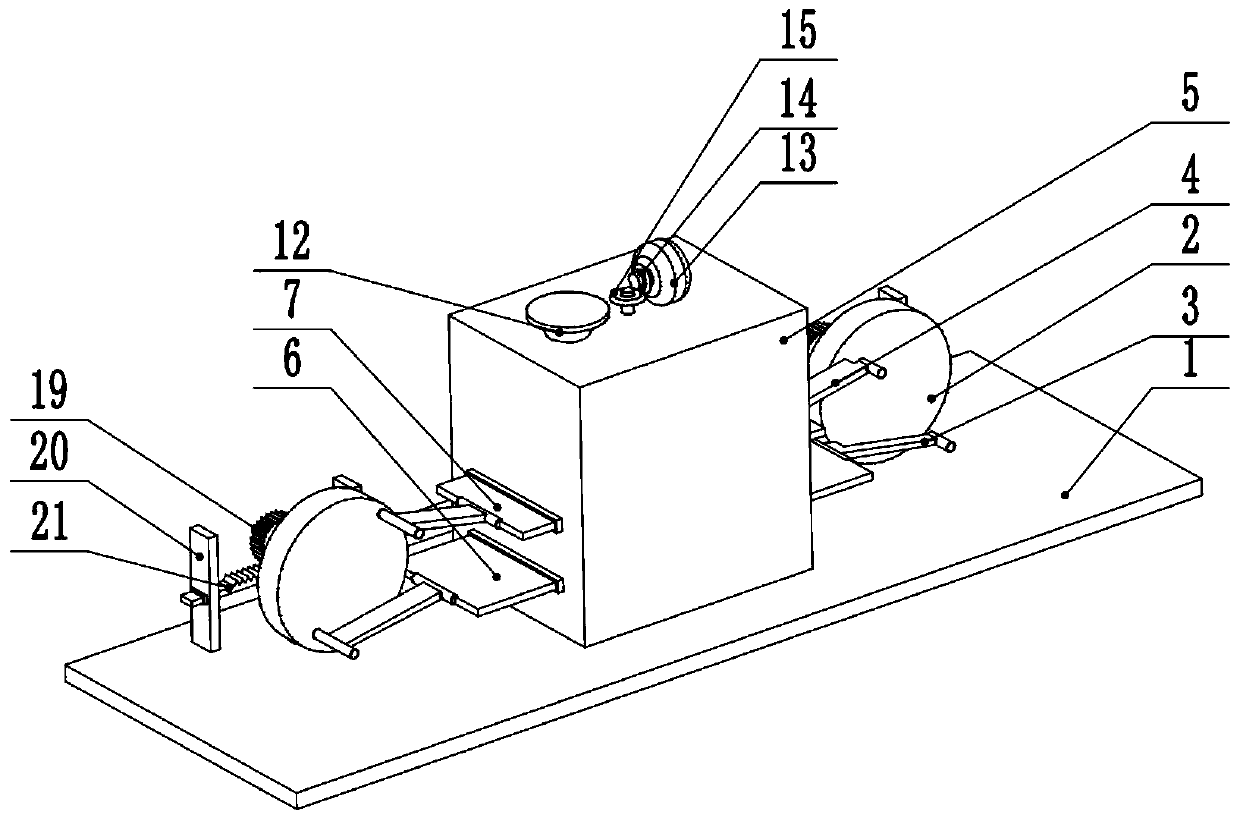

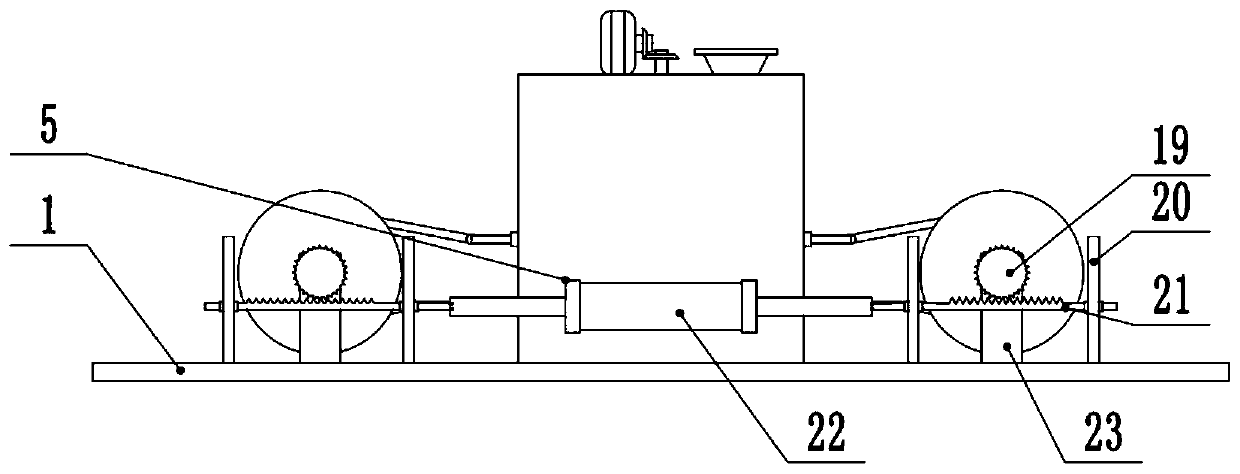

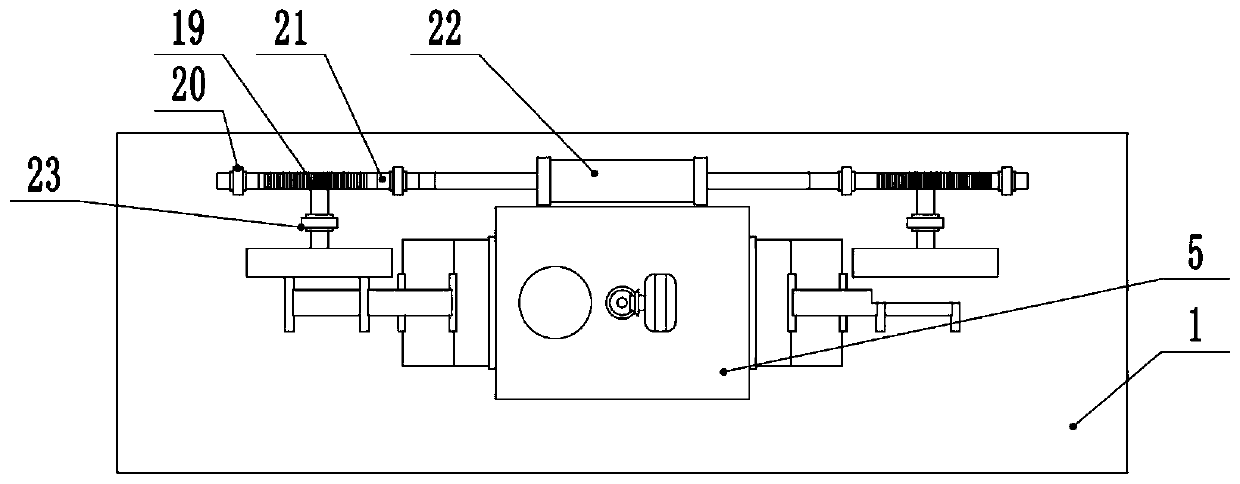

[0026] see Figure 1-5 , an environment-friendly solid waste treatment device, comprising a bottom plate 1, a reaction box 5 is provided in the middle of the bottom plate 1, a discharge port 12 is provided on the left side of the upper surface of the reaction box 5, and bearing seats 23 are provided on the left and right sides of the bottom plate 1, The bearing seat 23 is connected to the driving wheel 2 in rotation, the lower part of the driving wheel 2 is connected to the first connecting rod 3 in rotation, and the end of the first connecting rod 3 is connected to the baffle plate 6 in rotation, and the baffle plate 6 is slidably connected to the side wall of the reaction box 5. The driving wheel 2 The upper part is rotatably connected to the second connecting rod 4, the end of the second connecting rod 4 is rotatably connected to the push plate 7, the push plate 7 is fixedly connected to the pressure plate 9 on the middle side, and the bottom of the reaction box 5 is provide...

Embodiment 2

[0029] see Figure 4 , the other content of this embodiment is the same as that of the first embodiment, except that the right side of the air outlet 16 is rotatably connected to the rotating plate 17 . When the device is not in use, in order to prevent sundries from entering the device through the air outlet 16 and affecting the normal operation of the device, the rotating plate 17 is connected to the right side of the air outlet 16, and the rotating plate 17 is in a vertical position due to gravity, thereby The air outlet 16 is blocked, and when the air outlet 16 needs to be used, only the rotating plate 17 needs to be lifted.

[0030] During the implementation of the present invention, the drive motor 13 is started, and the drive motor 13 drives the rotating shaft 11 to rotate through the meshing first bevel gear 14 and the second bevel gear 15, thereby driving the crushing rod 10 to rotate through the rotating shaft 11. At this time, the material is opened mouth 12, put t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap